|

| Misfire? +code 25/35 (Page 3/4) |

|

Patrick

|

OCT 06, 08:31 PM

|

|

| quote | Originally posted by A_Lonely_Potato:

i am pretty sure i know EXACTLY how that screw got adjusted. While thinking of the best way to get the plug out, i decided to just grab the threads of the screw with some pliers, and whaddya know, it turns like a charm.

|

|

Is the screw so loose that it could've very slowly turned inwards on its own over the years (while the throttle was being held open)? If so, that might help explain a few other faster than normal idle speeds reported here.

The plug/cap is probably quite easy to remove. I suspect it's very thin metal and easy to collapse and pull out once it's been drilled.

And it might be an idea to "ding" the threads a bit so that the screw can't self-adjust again in the future![This message has been edited by Patrick (edited 10-06-2022).]

|

|

|

A_Lonely_Potato

|

OCT 06, 09:42 PM

|

|

| quote | Originally posted by Patrick:

Is the screw so loose that it could've very slowly turned inwards on its own over the years (while the throttle was being held open)? If so, that might help explain a few other faster than normal idle speeds reported here.

The plug/cap is probably quite easy to remove. I suspect it's very thin metal and easy to collapse and pull out once it's been drilled.

And it might be an idea to "ding" the threads a bit so that the screw can't self-adjust again in the future!

|

|

Possibly? It is pretty loose to turn, but the screw would have had to come down, or thread in against the spring for the idle to increase.

Shhh, i dont need your reasoning. My stubborness will keep me doing it the hard way. Then itll still look unmolested to boot

|

|

|

Patrick

|

OCT 06, 09:59 PM

|

|

| quote | Originally posted by A_Lonely_Potato:

Possibly? It is pretty loose to turn, but the screw would have had to come down...

|

|

Well sure, it would be easier for the screw to "come down" than to go up!

| quote | Originally posted by A_Lonely_Potato:

...or thread in against the spring for the idle to increase.

|

|

During the last four decades, I imagine the throttle's been opened a few times.

| quote | Originally posted by Patrick:

Is the screw so loose that it could've very slowly turned inwards on its own over the years (while the throttle was being held open)?

|

|

However you end up doing it, I think you're on the right track to getting the idle speed down.

|

|

|

A_Lonely_Potato

|

OCT 06, 10:33 PM

|

|

| quote | Originally posted by Patrick:

Well sure, it would be easier for the screw to "come down" than to go up!

|

|

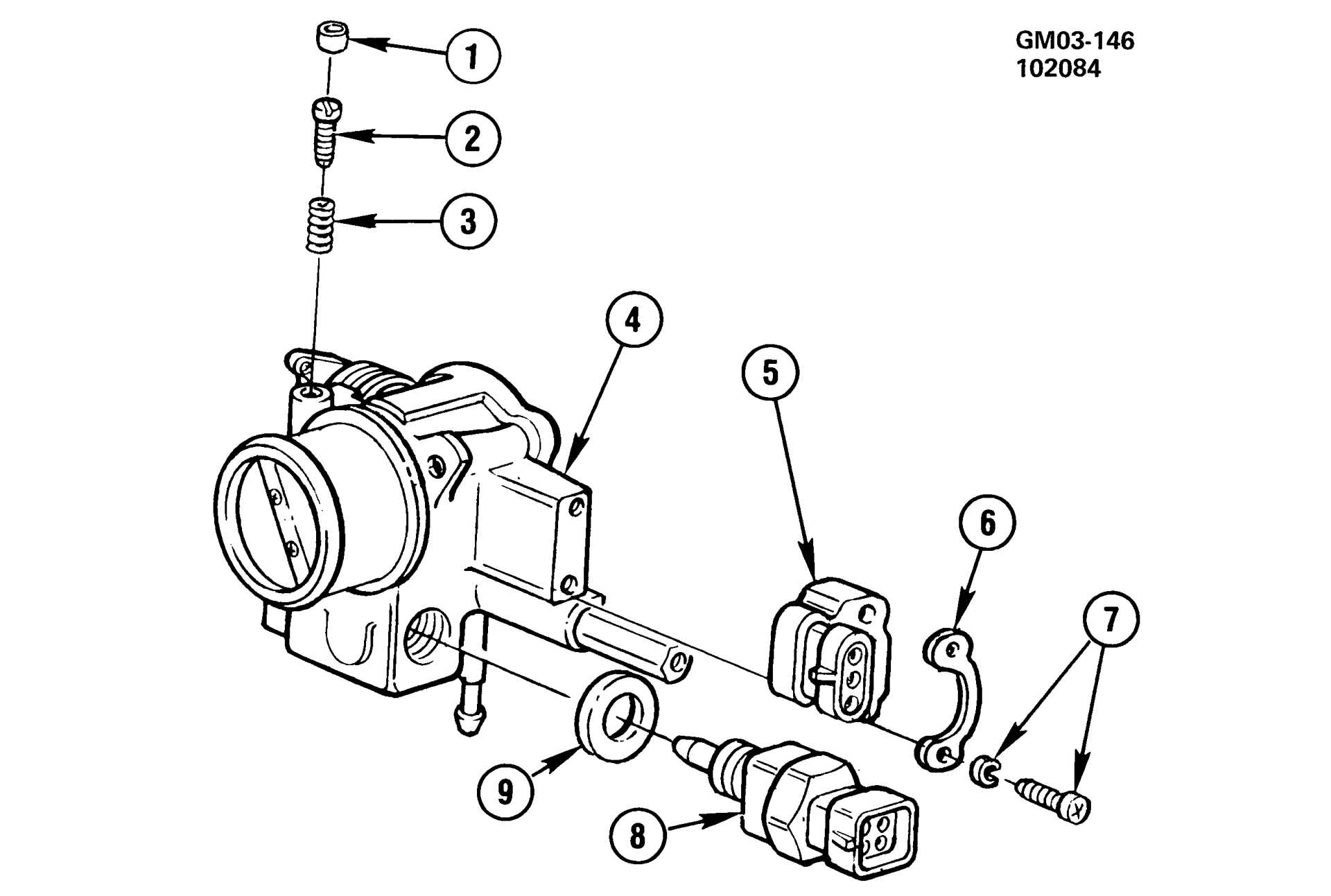

But in order for it to come down, it would be fighting against the spring that keeps tension on it. Not the Spring for the throttle itself, part 3 in this diagram

The throttle being open would remove *some* pressure, but unless that other spring is gone, it shouldn't be able to walk down.

|

|

|

Patrick

|

OCT 06, 10:44 PM

|

|

|

|

A_Lonely_Potato

|

OCT 09, 03:21 PM

|

|

|

Well i got the plate as closed as possible without stalling out. When i plug the IAC port the car will stall. But it still doesn't want to idle lower than 1.5k warm. When capturing the IAC closed as stated by avengador, the car will not start unless given a bit of throttle. I guess i should start looking at my fuel system now? I don't have a pressure gauge, i need to get one.

|

|

|

Patrick

|

OCT 09, 04:48 PM

|

|

| quote | Originally posted by A_Lonely_Potato:

I guess i should start looking at my fuel system now?

|

|

It's never a bad idea to know what the fuel pressure is while the engine is running, and how quickly it drops after the engine is shut off.

You should also determine what kind of readings your Coolant Temperature Sensor and Intake Air Temperature sensor are sending to your ECM. If you don't have a scanner or use WinALDL, this chart may help.

[This message has been edited by Patrick (edited 10-09-2022).]

|

|

|

A_Lonely_Potato

|

OCT 09, 05:33 PM

|

|

]

| quote | Originally posted by Patrick:

You should also determine what kind of readings your Coolant Temperature Sensor and Intake Air Temperature sensor are sending to your ECM. If you don't have a scanner or use WinALDL, this chart may help.

|

|

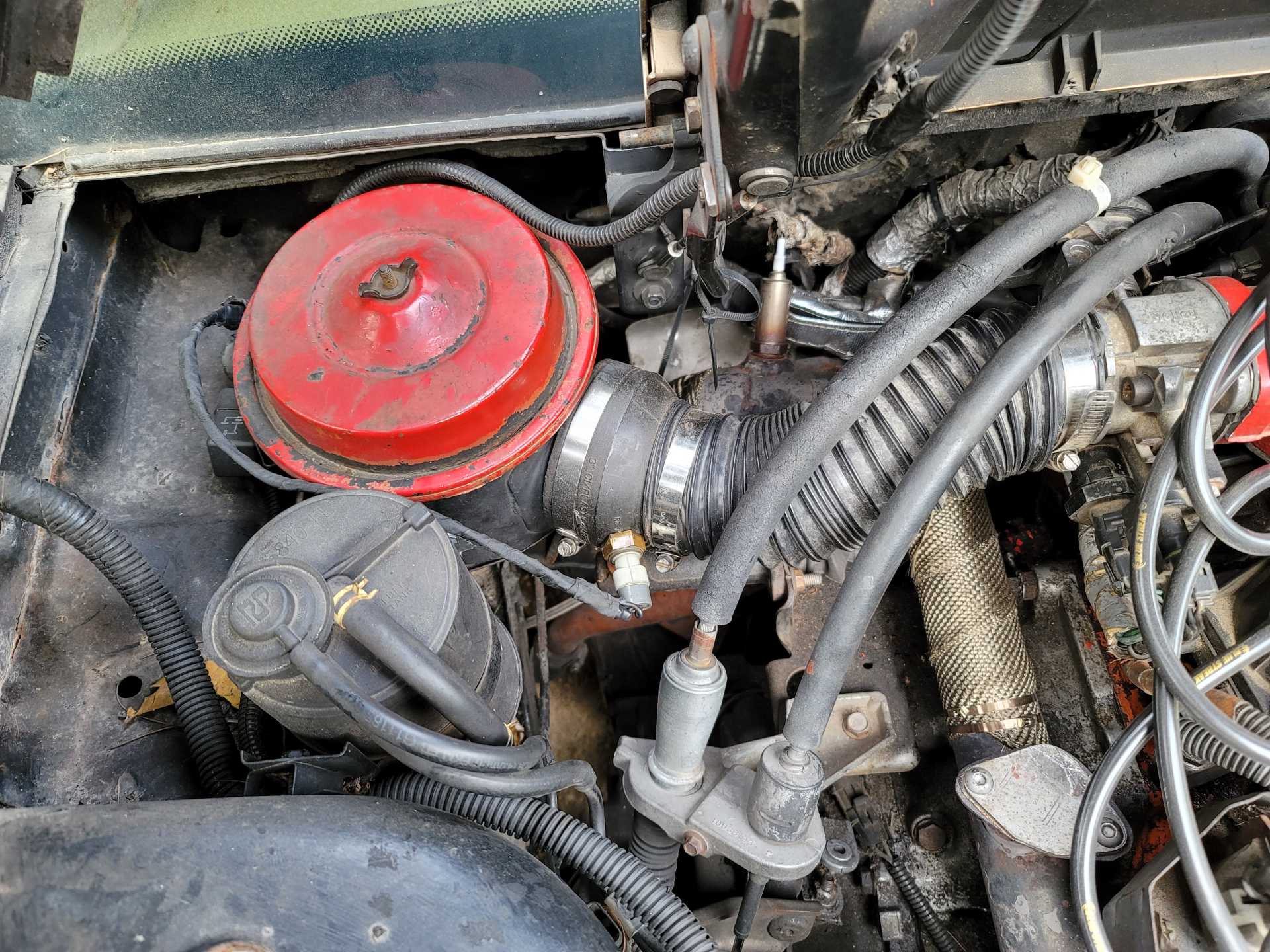

I only have a OBD2 reader, really want to get a winALDL cable but keep putting it off because its $50 that i dont want to spend haha. Tomorrow i will be driving around a fair bit so i will get better readings. Just now my IAT was reading about 70 degrees, which is probably accurate as my engine bay is still warm. CTS showed 130deg, but its been a while since the car ran so that doesn't really mean anything haha. One thought i had, is the positioning of my IAT might be throwing it off? A previous owner swapped the isuzu 5spd in, and the shift/select cables block the stock intake, so they rotated the air box for their own intake tubing. Well, the rotation of it puts the IAT bung perfectly centered on the fuel vapor canister. If i turn the box further to position the IAT bung on the inboard side of the vapor canister, then the decklid hinges hit the intake tube! So for now i am stuck with the whack IAT location.

[This message has been edited by A_Lonely_Potato (edited 10-09-2022).]

|

|

|

Patrick

|

OCT 09, 05:41 PM

|

|

| quote | Originally posted by A_Lonely_Potato:

|

|

Image fail. Newb.

I like to double-check on occasion that my CTS and IAT are basically reading the same as each other first thing in the morning (after sitting all night) before starting the engine.

|

|

|

A_Lonely_Potato

|

OCT 09, 06:28 PM

|

|

| quote | Originally posted by Patrick:

Image fail. Newb.

I like to double-check on occasion that my CTS and IAT are basically reading the same as each other first thing in the morning (after sitting all night) before starting the engine. |

|

Look again, your eyes decieve you in your advanced years.

Alright, ill give that a go in the morning

|

|

|

|