|

| Eff. My trans has internal break. Epoxy? (Page 3/5) |

|

Dennis LaGrua

|

APR 03, 04:32 AM

|

|

| quote | Originally posted by sourmash:

JB Weld responded Monday to an email I sent Sunday.

[QUOTE]

You can use our original JB Weld #8265S.

J-B Weld Support

P.O. Box 483 | Sulphur Springs, TX 75483

Ph: 903.885.7696 | Fx: 903.885.5911 |

|

[/QUOTE]

I've had good luck with JB weld repairs but not on aluminum. I'd still go with the alumaloy low temp brazing rods. to fix that. Of course you could try JB Weld and see what happens. You could always go back to the low temp aluminum rods if that doesn't work. What raises questions in my mind is the effect on submersion to trans fluid that the JB Epoxy would be subject to.------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

olejoedad

|

APR 03, 07:49 AM

|

|

The problem with aluminum is the porosity, it is difficult to remove all of the trans fluid from the broken metal area.

Solvent cleaning several times followed by heating the area to remove any trace of the contamination may work, but the odds are against you......the only way to improve your odds is to clean and heat the area many times....

From my experience in industry, the only thing that will work long term is to TIG weld the area and then file or machine to return to the original shape.

Seriously, I do not have much faith in an epoxy repair simply due to the extreme difficulty in properly and completely removing contamination from the porous aluminum broken casting.[This message has been edited by olejoedad (edited 04-03-2020).]

|

|

|

sourmash

|

APR 03, 10:39 AM

|

|

I took my old trans and pics of the current damage to the trans shop (to illustrate exactly where this circuit is located) before doing this band-aid. Maybe he already knew since I took it down for them to diagnose. Maybe I'm reading too much into his opinion but his statement was that a shift solenoid is still the reason it wouldn't shift. So I'm suspecting maybe he knows and that this is not a primary forward operating circuit--or won't prevent adequate operation. I'm wondering if this is PERHAPS the reverse circuit which did operate, but was quite slow to respond when gear selected.

But I ordered and received the lower valve body separator plate pictured above and have the 2 shift solenoids. Hopefully this weekend we'll see what happens. I should've done the shift solenoids before having them install the trans. I would've seen the damage. A shift solenoid letting go is what destroyed the original trans, so it was a miss on my part initially. They still should'vel told me. They should've cleaned the replacement pan out and cleaned the wiring insulation and grenaded pieces from the hockey stick strainer screen before taking them off the old trans and installing. I have a suspicion the workers want a used trans to fail.

Anyway, here's the repair before shaping it down. It's just a plug and held in place by the hole in the wall and shouldn't blow out if it's not high pressure. It can erode though or a piece could break loose. My wax paper wrinkled and caused a divot (where it doesn't really matter once it was shaped). But for anyone using epoxy putty, you should use a large deep well socket that would roll over the area instead of dragging something across it. Put the wax paper over it and roll the socket across it like a rolling screed. That way you don't have to shape it much. The metal separator plate between the valve bodies has paper gasket material bonded to it so it will take up some small deviations.

[This message has been edited by sourmash (edited 04-03-2020).]

|

|

|

sourmash

|

APR 04, 05:08 PM

|

|

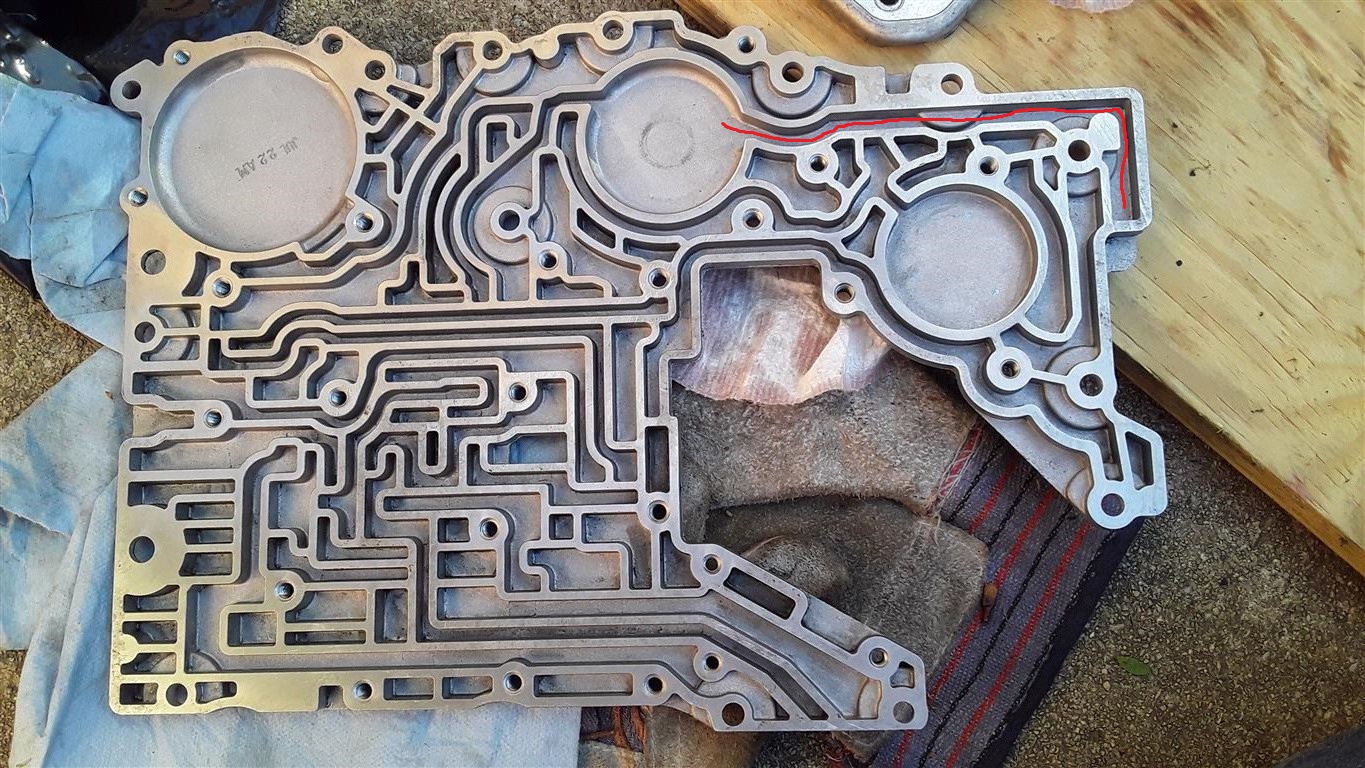

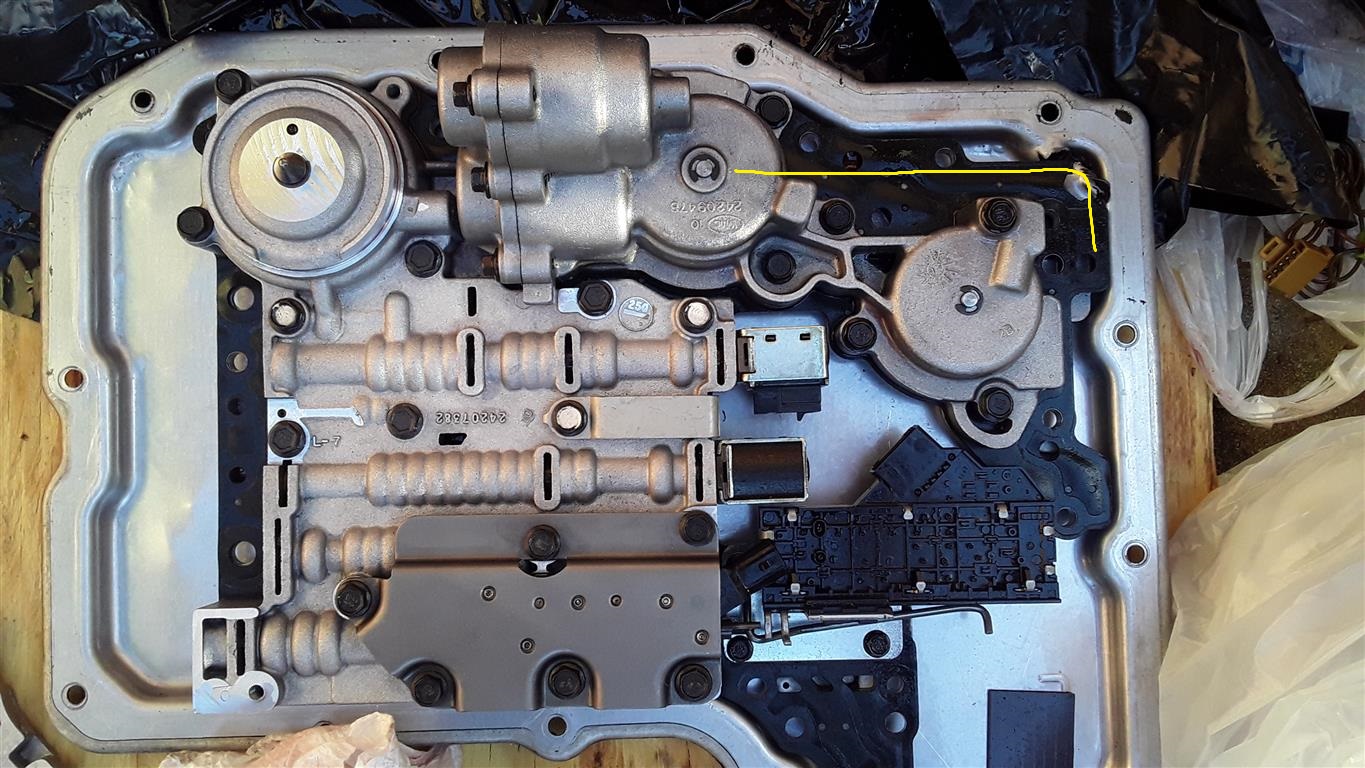

Anyone recognize what this circuit is that was broken open? And what the device is that it's coming from? This is the good channel plate with the red line. The yellow is from the valve body that sits above the channel plate.

|

|

|

theogre

|

APR 04, 11:51 PM

|

|

The large round thing at end of red path?

Quick guess likely an accumulator. Several ways can be used and can have more then one job too. Examples:

Can be used to store pressurize oil so whatever part acts fast. (Main pump etc will have problems keeping up w/ fast flow for some parts.)

Can be like a Hammer Stop for household pumping to prevent things from breaking.

Can be both depending just how valve body is design.

|

|

|

sourmash

|

APR 05, 01:03 PM

|

|

Ok, thanks. really curious to see if anything is repaired when this is done but it won't be this weekend.

Turns out I got half good and half bad advice on shift solenoids. The info given was that the 2 shift solenoids were the same, but aren't. For my 2000-2001 built trans there are 2 different numbers. The 1-2 solenoid is rotated 90 degrees in the metal housing from the 3-4 solenoid to clear the channel plate. They have different plugs to differentiate them. Other than the plug everything is the same, just oriented differently. I believe the 98-99 one they might be the same since they install the same rotation. Note the tan plastic part is rotated in the pic. The electric plug colors correlate to the part number.

|

|

|

OldsFiero

|

APR 06, 07:36 AM

|

|

The broken passage is 2nd clutch oil to the 1-2 accumulator piston. Will cause slipping or no 2nd and burned clutches.

Marc

|

|

|

sourmash

|

APR 06, 08:02 AM

|

|

Makes sense why it wouldn't shift automatically to 2nd then.

To make it operate in 2nd from a dead stop I had to pull the lever to 2nd and start out. It would shift from 1st to 2nd as normal. And if I waited until higher RPMs to manually move the lever to 3rd or D it would properly shift to 3rd and onward. However if I manually shifted to 3rd too soon it would freewheel with no forward motion as it tried to fall back to 1st gear. If I started out in D it would take off in 1st and never shift until RPMs were high enough to take on 3rd.

|

|

|

OldsFiero

|

APR 06, 10:15 AM

|

|

The 4th band is applied in manual 2nd to provide engine braking, thus holding the reverse drum instead of the 2nd clutch.

Marc

|

|

|

sourmash

|

APR 07, 08:57 AM

|

|

|

These are things the trans shop wouldn't tell me. They really must just want to do full rebuilds only and actually have done 2 for me, plus others for family. All performed well. My 98 Tahoe for $1000 in 2005 and 84 Cavalier in the mid 90s I had rebuilt while replacing the engine.

|

|

|

|