|

| The White Bug (Page 22/46) |

|

Will

|

AUG 24, 10:34 AM

|

|

| quote | Originally posted by pmbrunelle:

Do you know why Spec (as an example) lists different part numbers for the 4-speed vs. 5-speed? I guess I could ask them.

I was also wondering if the clutch release fingers are at the same distance from the flywheel regardless of 4-speed vs. 5-speed.

The throw-out bearing is on my transmission, so I expect to keep that. |

|

The clutch supplier has to box the pressure plate, disk and throw out bearing in the same package, so they need a different BOM for a package going for the Muncie vice Getrag vice Isuzu.

| quote | Originally posted by pmbrunelle:

I'm not really sure what that involves. If I sift through your build thread "The Mule rides again (sort of) - pics." will I find information on that?

This is my wishlist of minimum specifications:

410 lb*ft engine torque

50000 km lifespan

Ability to slip the clutch for stop+go traffic

Moment of inertia not critical; shift time (well, synchronization) is slow with my current setup, but I accept that.

I don't know if there exists a solution that satisfies the above wishlist; I have some research to do. |

|

Torque capacity with a dual disk is easy. Most 7.25" MFG's have multiple springs to tailor clamp load, and of course a dual disk clutch has twice the capacity of a single disk.

I'm working on the fitment, so I have no idea what the service life would be... which is STRONGLY dependent on usage characteristics anyway.

A couple of members here have done dual disk clutches, and I've asked elsewhere. What I've gleaned is that with organic disks they work in traffic, although still not as friendly as a production style clutch.

QuarterMaster has a part number (probably hasn't made any for a long time) for a bolt-in flywheel for the V6 (Well... SD4). I even have one. I had to build one from scratch for the Northstar.

There's a good aftermarket built around the 7.25" racing clutch "architecture". All the MFG's recognize that it's in their best interest to make sure that another MFG's customer can bolt in one of their clutches. Thus they all use the same mounting bolt circle and locating journal diameter.

Stack heights and setup heights vary considerably depending on configuration. Configurations can vary from two 0.100" sintered iron disks to two 0.200" cerametallic or organic disks to two 0.250" cerametallic or organic disks. A clutch with two 0.250" disks will just *BARELY* fit in the 282 bellhousing. The Muncie has a slightly deeper limiting depth in the bellhousing, so the same configuration should fit there.

There are no Muncie, Isuzu or Getrag-specific throw out bearing holders. (QM might have one for the Muncie, but I don't know the PN; haven't looked either)

This is Tilton's TOB for their clutches: https://www.summitracing.com/parts/til-62-002-5

Clearly it needs a holder, which needs to be specific to the transmission.

The top of the pressure plate cover is the tallest part of the clutch, with the diaphragm spring fingers "below" that. The holders end up being fairly tall as a consequence.

Once it fits mechanically, the next issue is that the 7.25" clutches have a short throw with a high throw out load. That's a throw in the range of 0.250" to 0.300" with a load as high as 500#. The production clutches have throws more like 0.500-0.625" and loads in the 250-300# range.

Setting the entire 7" of Fiero pedal travel to reduce to a 0.300" throw results in a 22# pedal load on a 500# throw out load. That's actually quite light, but requires just the right system in between the pedal and the clutch.

Since all of the Fiero throw out systems (Muncie, Isuzu, Getrag, F23, F40) are designed for a fairly consistent set of throw & load characteristics, the adaptation method that comes to mind for me which should be applicable to all is a hydraulic ratio divider. That would be a hydraulic device in which the master cylinder pushes fluid into a large diameter piston which mechanically pushes on a small diameter piston, which pushes fluid to the slave cylinder (or are "leader cylinder" and "follower cylinder" now the politically correct terminology?). I think one hydraulic divider design could accommodate all 5 of the configurations I listed above, but I haven't collected enough data from the various systems to make sure that I select a ratio that hits the "sweet spot" that covers all five.[This message has been edited by Will (edited 08-24-2020).]

|

|

|

pmbrunelle

|

AUG 24, 08:32 PM

|

|

| quote | Originally posted by Will:

The clutch supplier has to box the pressure plate, disk and throw out bearing in the same package, so they need a different BOM for a package going for the Muncie vice Getrag vice Isuzu. |

|

Now I understand!

********************************************************************************

That was a thorough yet succinct explanation of the 7.25" form-factor clutch architecture.

For the moment I want to buy something and bolt it on relatively quickly so I can continue tuning this setup. So no 7.25" clutch for now.

********************************************************************************

Nevertheless, it is still interesting to discuss the 7.25" clutches.

Is there a reason that the throwout bearing/release mechanism native to each transmission cannot release the 7.25" clutch? Packaging problem because the fingers are too sunken in, and therefore difficult to reach? Do you think that the hydraulic pressure needed to release a 7.25" clutch would damage a factory HTOB? On an external-slave transmission, do you think the fork could be damaged from excessive force?

For the external-slave transmissions, at first glance, either a longer release lever, or a bigger-bore slave would seem to be less kludgy solutions than a stepped piston deal.

|

|

|

Will

|

AUG 25, 08:31 AM

|

|

| quote | Originally posted by pmbrunelle:

Nevertheless, it is still interesting to discuss the 7.25" clutches.

Is there a reason that the throwout bearing/release mechanism native to each transmission cannot release the 7.25" clutch? Packaging problem because the fingers are too sunken in, and therefore difficult to reach? Do you think that the hydraulic pressure needed to release a 7.25" clutch would damage a factory HTOB? On an external-slave transmission, do you think the fork could be damaged from excessive force?

For the external-slave transmissions, at first glance, either a longer release lever, or a bigger-bore slave would seem to be less kludgy solutions than a stepped piston deal. |

|

The throw out bearing holders for the OE style clutches don't put the throw out bearing in the right location/depth for the 7.25" clutches. Thus each transmission needs either a holder specific to its mechanical release mechanism or a modification to the HTOB. I haven't looked at the Muncie fork specifically, but the Getrag fork seems to be fine with the extra load in the few cases that have gone to dual disk clutches. It's less than double the original load. If I can package it, I'll include ball bearing trunions on the holder(s) to eliminate sliding contact and the resultant wear.

Higher pressures in the HTOB shouldn't be a problem... after all, brake calipers handle MUCH higher pressures than the clutch hydraulics see. Seals should be similar between the two.

For one external slave transmission, I'd build a bigger slave and call it done. For three with different slaves, different arms and different brackets that solution is more work. For FIVE choices with two being less practical for making a slave, the hydraulic divider is the only option I see that covers all five with one solution.[This message has been edited by Will (edited 08-25-2020).]

|

|

|

pmbrunelle

|

SEP 04, 12:28 AM

|

|

I ordered a Spec stage 3+ clutch this week.

********************************************************************************

I worked on the tuning the X-Tau model this past week, whereby the ECU multiplies the fuel injection quantity by the inverse of the fuel puddle's low-pass transfer function. It is an attempt to cancel the fuel delivery lag effect of the fuel puddle in software.

In practice, perfect cancellation is not possible. I initially tried X-Tau with "ideal" coefficients, but they resulted in too much noise/variation in fuel delivery. The resulting torque variation was objectionable when cruising at constant speed. Perfect cancellation of the fuel puddle would require the ECU's X-Tau transfer function to have very high gain as frequency increases; not necessarily practical. Depends on the noise of your sensors I guess.

My dad helped with this; he drove the car while applying throttle steps at different RPMs. I was recording things with the laptop and adjusting stuff.

I did achieve partial puddle compensation with X-Tau; good enough that TPS-based accel enrichment is not necessary with the engine warmed-up. The throttle response was still a bit more snappy with TPS-based accel enrichment, so I kept it, but at a reduced level. I still rely heavily on TPS-based accel enrichment following a cold start.

Overall I am happy with how the AFR tracks the AFR target now. Here is a 1-2-3-4 WOT run:

There is a lean spike on the 3-4 shift, but it wasn't perceptible on the butt dyno, so I'm fine with that. I believe that this fast short spike can happen when the throttle opens fast, between the injection quantity calculation, and the intake valve swallowing air.

During gearchanges, I don't manage to bring back the AFR to stoich; that's OK, it doesn't cause a driveability problem, just pollution.

We can see why (among other reasons) cars have moved to drive-by-wire, but (as a consumer) I prefer the paradigm where the driver is the master of his car, and the ECU must accept and cope with the situation it's been put into.

I don't know if MegaSquirt is able to extend an in-progress squirt, or if once it's been started, the duration is fixed.

1st gear WOT suffered from a leaner AFR than in other gears. At first, I blamed the fuel delivery delay (during hard acceleration) due to the fuel puddles. I then found that software filtering of RPM and MAP signals were largely responsible for making the fuel delivery lag behind the engine's fuel needs. So I reduced the amount of RPM/MAP filtering, and things are better in 1st gear now.

********************************************************************************

With La Fiera's injectors, I haven't noticed much different in how the engine runs hot, at the present boost level.

The biggest improvement was in cranking and starting the engine.

With the Accel injectors, I had a hard time to inject the correct amount of fuel when cranking. It was not easy to find the happy medium between flooding the engine, vs. firing up quickly.

With the Green Giant injectors, the tuning window was wider; I converged on a suitable cranking fuel quantity quickly. I suppose that they make a better quality mixture.[This message has been edited by pmbrunelle (edited 09-04-2020).]

|

|

|

pmbrunelle

|

SEP 18, 09:36 PM

|

|

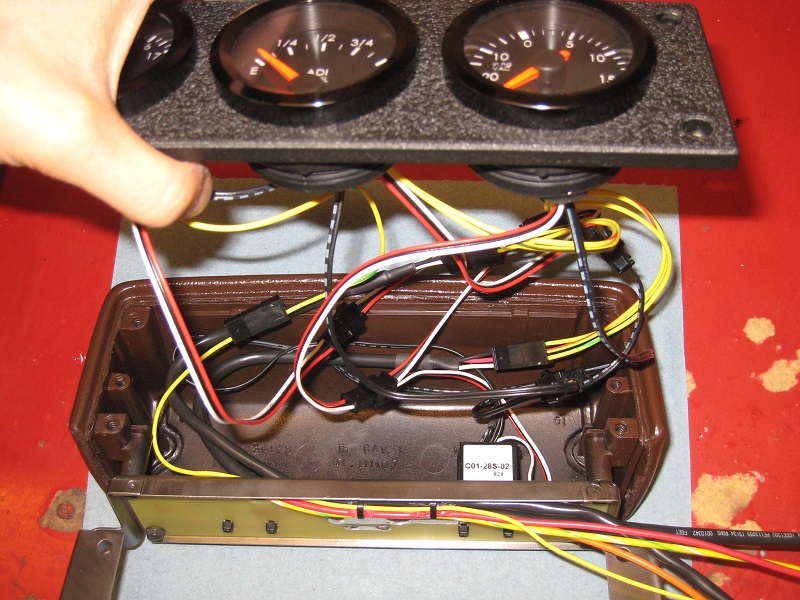

I installed three Speedhut gauges in the aux gauge pod. I used one of the 3-hole aluminium mounting plates available on ebay. I primed it with yellow zinc chromate, and then topped it with black VHT wrinkle paint.

AFR

ADI Level (i.e. the amount of juice in the Anti-Detonant Injection tank)

Boost

Since I have an 85 V6, the oil pressure is already combined into the factory tach.

The Speedhut gauges are quite shallow, and thus good for mounting in situations with low clearance behind the mounting panel, such as the aux gauge pod.

I am not super-happy with having the gauges on the aux gauge pod like that. They're a bit hard to see from the driver's position.

I could always build a replacement mounting plate with angled mounting surfaces, to orient the gauges more towards the driver. However, I feel that alienates the passenger, and I want to be able to see the gauges when I'm the passenger/tuner.

So they will remain on the flat panel for now, in the compromise position.

Illumination of Speedhut gauges is somewhat underdeveloped. According to Speedhut, the LED needles aren't dimmable, and the electroluminescent faces are only dimmable via a potentiometer on an external inverter box:

https://www.speedhut.com/ec...e-Gauges-with-Dimmer

I was able to make the EL inverter box work like stock by cutting off its pot, and varying its input voltage by powering it from the Fiero dimmer. I installed a series diode to drop the voltage some 0.6 V.

For the LEDs, I installed a 2.2 kOhm resistor in series with the LED supply wire (for three gauges), and then connected that to the Fiero dimmer.

Now the Speedhut gauge lighting matches that of the Fiero gauges, even as I use the Fiero dimmer to vary the gauge brightness. Still, I shouldn't have had to add external parts, plus finding a place to mount the external inverter box took some head-scratching.

|

|

|

Honest Don

|

SEP 22, 10:25 AM

|

|

|

|

pmbrunelle

|

SEP 22, 12:51 PM

|

|

Thanks!

Adding external parts (single resistor, diode) is one of the harder mods to do on a car, since you can't just leave these things loose in the harness, subject to the leads flexing. If you really just have one part to add to a harness, I was thinking of using an inline ATO fuseholder. Two spade terminals could be soldered to the component, and the assembly could be plugged into the fuseholder.

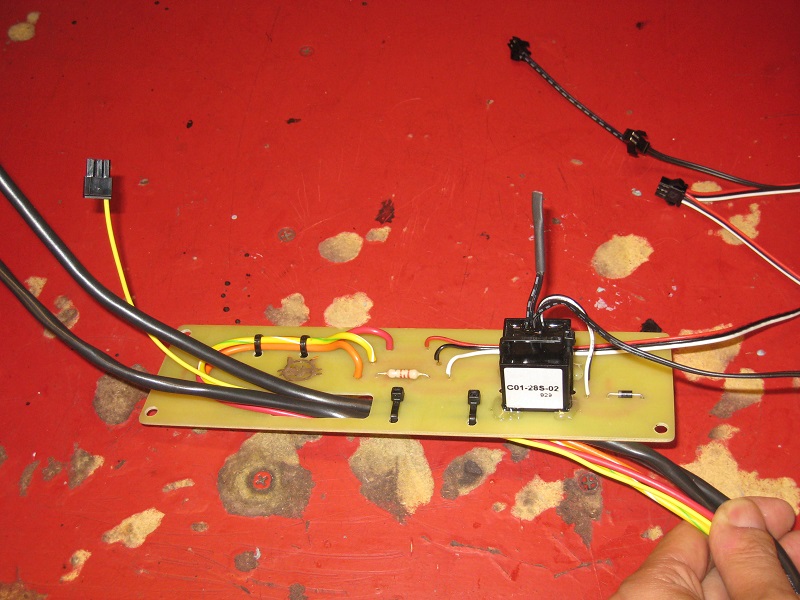

I ended up making a board to support the loose parts, and to provide strain relief for the wires. The board goes installs underneath the stock gauge pod, sandwiched below the stock screw heads.

|

|

|

La fiera

|

SEP 22, 09:08 PM

|

|

| quote | Originally posted by pmbrunelle:

*******************************************************************************

With La Fiera's injectors, I haven't noticed much different in how the engine runs hot, at the present boost level.

The biggest improvement was in cranking and starting the engine.

With the Accel injectors, I had a hard time to inject the correct amount of fuel when cranking. It was not easy to find the happy medium between flooding the engine, vs. firing up quickly.

With the Green Giant injectors, the tuning window was wider; I converged on a suitable cranking fuel quantity quickly. I suppose that they make a better quality mixture.

|

|

That is because despite being bigger, they atomize the fuel better thus improving combustion. Glad you are taking advantage of them!

|

|

|

pmbrunelle

|

SEP 26, 06:05 PM

|

|

I got fairly acceptable highway fuel economy yesterday, despite that fuel economy was low on the list of priorities for this build.

I filled up, and drove 196 km, almost all on the highway at about 110 km/h. I did not test accelerations, which would burn more fuel.

I averaged 9.5 L/100 km for that trip. That's 25 mpg for you Yanks.

I never did a similar test with my old Accel injectors, but I think we can say the combo with the Bosch injectors is working well.[This message has been edited by pmbrunelle (edited 09-26-2020).]

|

|

|

La fiera

|

SEP 26, 09:01 PM

|

|

Glad you are making progress Patrick! Glad you are making progress Patrick!

|

|

|

|