|

| The White Bug (Page 21/46) |

|

Franked

|

AUG 13, 09:27 AM

|

|

I've been reading every page of this, just caught up. Very nice build!

So.. I am not going to be the only one to ask, what was your 1/4 mile time?

|

|

|

pmbrunelle

|

AUG 13, 12:55 PM

|

|

| quote | Originally posted by Honest Don:

At what increment are you advancing timing? |

|

For initial setup, I got the car running with a boost retard of 0.3 °/kPa, relative to the values I have in the 100 kPa row. It worked, and when my wastegate wasn't working right, I overboosted to 200 kPa a few times without issue.

I realized with that much slope, I wouldn't have any advance left in the higher boost regions. So I reduced the slope to 0.2 °/kPa. I drove around like that until this week (on wastegate spring pressure, about 150 kPa).

Last weekend when I raised the manifold pressure to 175 kPa, I noticed (on the butt dyno) that the engine seemed to fall flat on its face, despite 25 kPa more pressure. I concluded that the boost retard was excessive, and I reduced it to 0.12 °/kPa (as in the table pictured above). The car feels much better like this. Since the car feels good like this now, I'm going to leave the ignition timing the way it is.

I will drive around at 175 kPa on the current tune for at least a month or so to make sure everything is OK at this boost level.

If all goes well, then I will look into increasing the manifold pressure to 200 kPa (with water injection). At that point I may decide if I still like the ignition timing table or not.

I am not advancing the timing until the onset of knock, then backing off. Since I have low compression (and water injection), I suppose that I can set the timing to MBT, rather than being knock-limited. Overadvancing the timing beyond MBT to the knock limit would be counterproductive. This engine really does not exhibit any tendency to knock.

Once I get the tune roughed in as good as I can get it by street/dragstrip/estimation methods, then I may book some time on my local tuning shop's Dynapack dyno. This would allow me to more precisely find the MBT (if not knock-limited) spark advance in the high boost region.

| quote | Originally posted by Honest Don:

Results? |

|

| quote | Originally posted by Franked:

So.. I am not going to be the only one to ask, what was your 1/4 mile time? |

|

My best time so far remains 14.122 s @ 97.62 mph, with 150 kPa manifold pressure:

http://www.fiero.nl/forum/F...HTML/098801.html#p21

I didn't beat that time on 175 kPa last Saturday due to:

1. I simply cranked up the boost (earlier the same day) without really adjusting the tune.

2. I wasn't feeling sharp that day. I had a run where I missed a shift, and another where I launched with massive wheelspin. I decided to stop, and enjoy watching other people race.[This message has been edited by pmbrunelle (edited 08-13-2020).]

|

|

|

pmbrunelle

|

AUG 17, 12:17 AM

|

|

Unsurprisingly, my sketchy water injection system failed. Eric called this one!

It's been more than a year since the initial setup, so I figured that the stagnant water might corrode things enough to cause problems.

Therefore, before cranking up the boost further, I wanted to make sure that the system was functional. I didn't trust it...

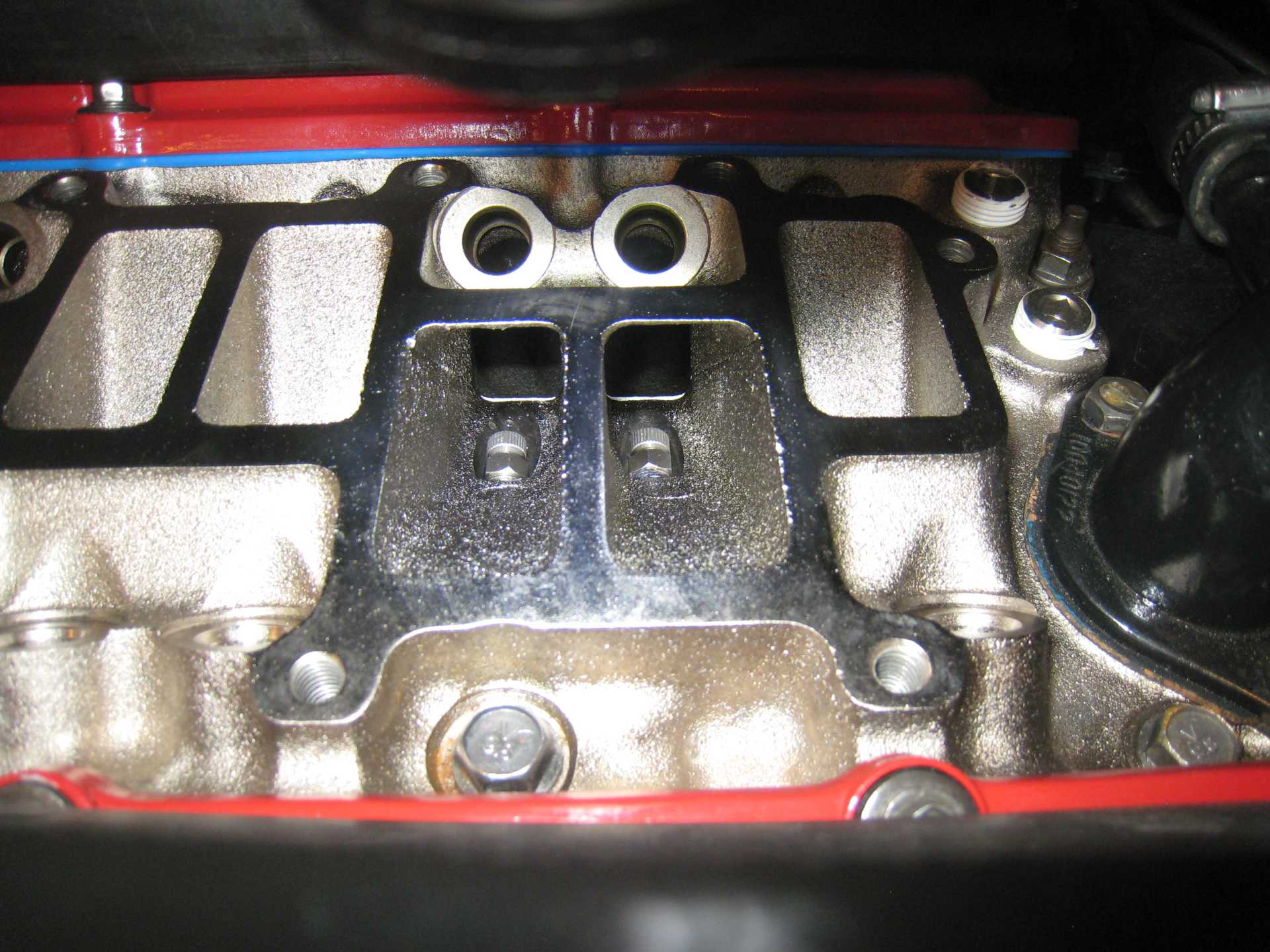

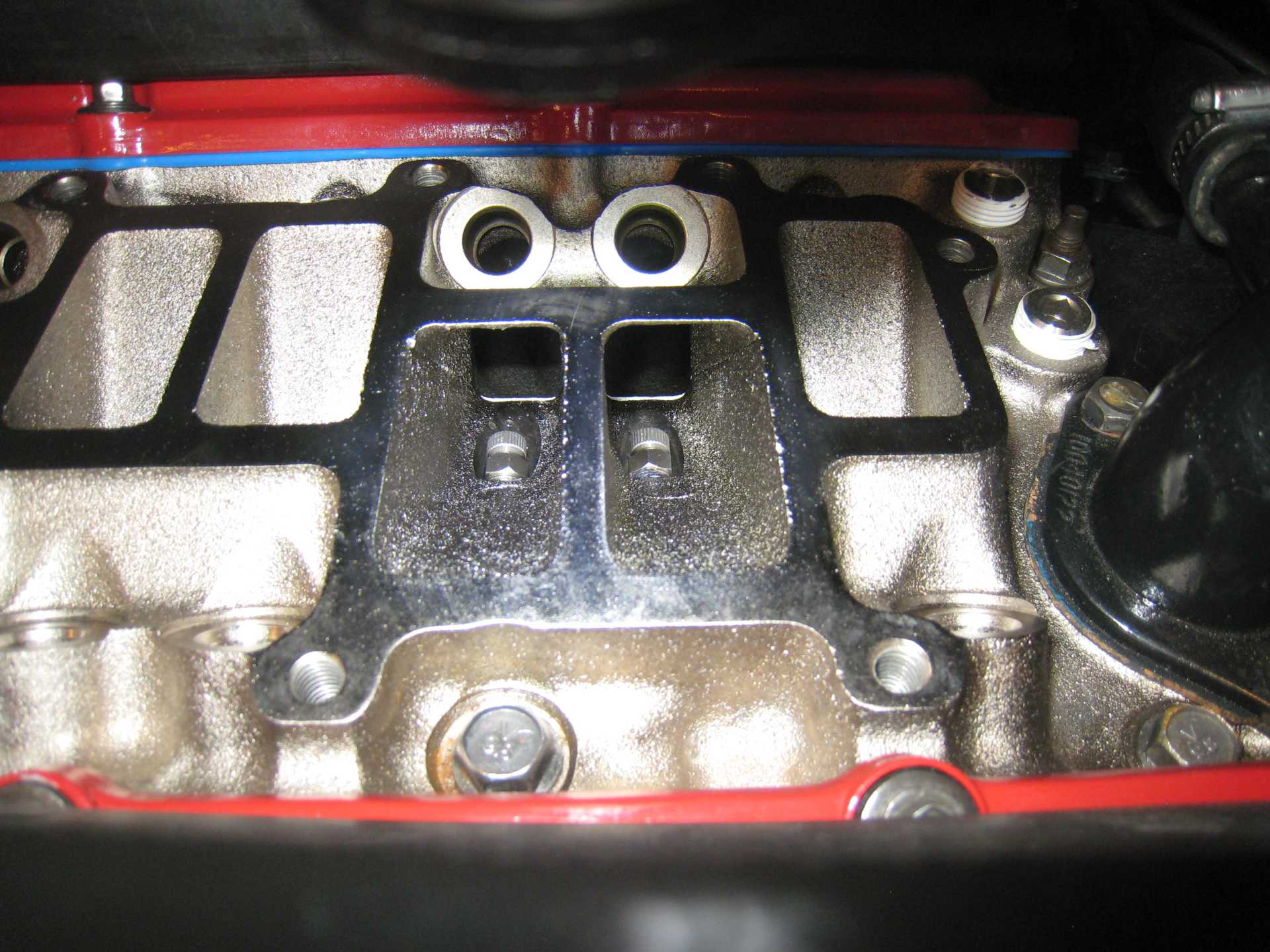

I removed the upper and middle intakes; this gave me a view of the intake runners and the water nozzles:

Then, my plan was to turn on the water; long enough to observe the water spray, without flooding the engine with water.

Well, the nozzles just dribbled a small amount of water. Good thing I decided to check up on things before increasing the boost.

I then removed the lower intake, and the nozzles.

Here is a view of one of the nozzles:

The (previously) white object is a plastic foam filter that is pushed in the inlet hole of the nozzle.

It seems like green bacterial slime grew on the filters (all six), blocking the filters.

I then reinstalled the same nozzles into the intake, but with the filters removed, and they sprayed like usual. Problem identified!

I think I'll be reassembling the engine without the filters on the nozzles, since the bacterial blockage could return if I reinstall new filters. They seem to like this plastic.[This message has been edited by pmbrunelle (edited 08-17-2020).]

|

|

|

pmbrunelle

|

AUG 19, 11:08 PM

|

|

I screwed the water nozzles (without filters) into the intake manifold, then I bolted the intake onto the engine.

Since RTV is used to seal the intake to the block, I decided to wait a few days for the RTV to cure, before driving the car again.

I am using this RTV-curing downtime to perform other jobs on the car, without extending the overall project schedule.

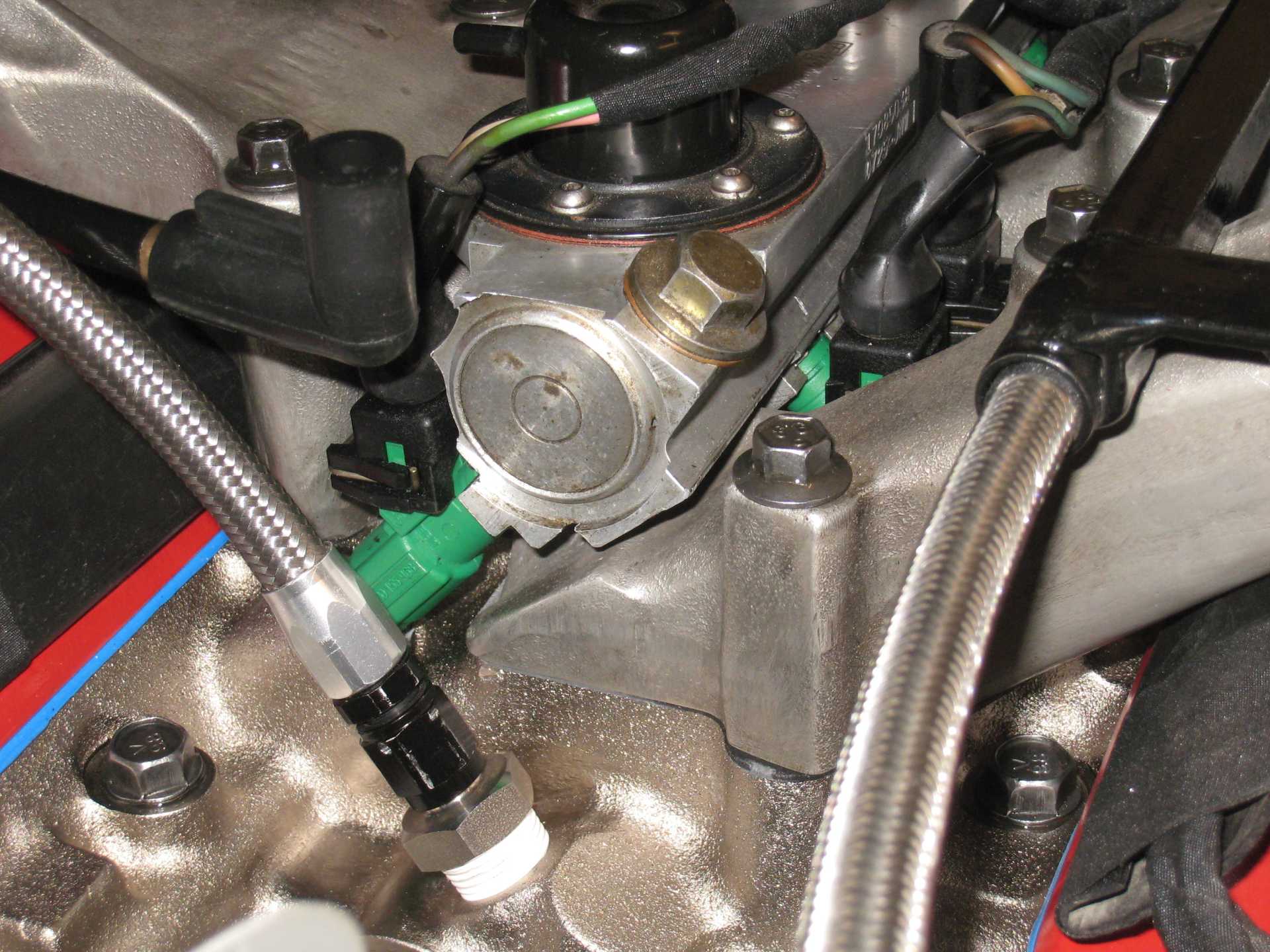

I installed the Bosch "Green Giant" fuel injectors, courtesy of La Fiera:

I didn't have the injector test jig ready, so I will simply tune the dead times in the car.

To confirm that the injector dead time is correct, I will switch the fueling between 1 squirt/cycle and 2 squirts/cycle.

If the measured lambda remains constant, regardless of the number of squirts, then I conclude that the dead time compensation is correct.

|

|

|

Will

|

AUG 20, 08:00 AM

|

|

| quote | Originally posted by pmbrunelle:

Unsurprisingly, my sketchy water injection system failed. Eric called this one!

It's been more than a year since the initial setup, so I figured that the stagnant water might corrode things enough to cause problems.

Therefore, before cranking up the boost further, I wanted to make sure that the system was functional. I didn't trust it...

I removed the upper and middle intakes; this gave me a view of the intake runners and the water nozzles:

Then, my plan was to turn on the water; long enough to observe the water spray, without flooding the engine with water.

Well, the nozzles just dribbled a small amount of water. Good thing I decided to check up on things before increasing the boost.

I then removed the lower intake, and the nozzles.

Here is a view of one of the nozzles:

The (previously) white object is a plastic foam filter that is pushed in the inlet hole of the nozzle.

It seems like green bacterial slime grew on the filters (all six), blocking the filters.

I then reinstalled the same nozzles into the intake, but with the filters removed, and they sprayed like usual. Problem identified!

I think I'll be reassembling the engine without the filters on the nozzles, since the bacterial blockage could return if I reinstall new filters. They seem to like this plastic.

|

|

You're not just going to convert the nozzles to a "Sneaky Pete" direct port Nitrous system?  [This message has been edited by Will (edited 08-20-2020).]

|

|

|

pmbrunelle

|

AUG 21, 12:44 PM

|

|

It's almost as if GM made the factory manifold-in-a-manifold for hotrodders.

I'm surprised that I haven't seen the IAC passage being used more often (to administer whatever substance) by 2.8 Fiero hotrodders.

|

|

|

Will

|

AUG 21, 03:15 PM

|

|

I think someone's done something like that at some point, but I don't recall specifics.

Unfortunately, the idle air distribution passages are probably terrible for cylinder-by-cylinder wet flow distribution.

|

|

|

pmbrunelle

|

AUG 23, 01:24 AM

|

|

| quote | Originally posted by pmbrunelle:

Now the injectors are really maxed out (94% duty cycle observed).

|

|

With the Green Giant injectors, peak duty cycle is now 61%.

Good, there's now plenty of headroom to increase the boost further!

...except for:

| quote | Originally posted by fierosound:

If the RAM clutch fails, consider Canadian made Bully Clutch. I have the same one in both my cars.

2 others here in Calgary have also bought them. (one is 3800 S/C, the other a 3400/Turbo)

We all got Stage 3. Light pedal effort, not "grabby" but high clamping and work great.

http://www.fiero.nl/forum/Forum2/HTML/129057.html

|

|

Well, it happened...

When I go WOT in 4th gear, as the engine hits its torque peak of ~3500 RPM, the RAM 9.75" HD clutch slips. The hot summer days are largely behind us here, so I think that the cooler air helped the engine produce more torque.

Tony, do any of your Fiero friends with this clutch have a Muncie like me, or do they all have Getrags? I'm wondering if this clutch can work with my transmission. Bully doesn't seem to list any Muncie 4-speed applications on their website.

Also if anyone else has an opinion regarding Muncie/Getrag clutch interchangeability, feel free to chime in. Or simply a recommendation for a Muncie.[This message has been edited by pmbrunelle (edited 08-23-2020).]

|

|

|

Will

|

AUG 23, 06:30 AM

|

|

The pressure plate, disk and flywheel are the same. The throw out bearing is different.

Interested in a dual disk 7.25"?

|

|

|

pmbrunelle

|

AUG 23, 12:38 PM

|

|

| quote | Originally posted by Will:

The pressure plate, disk and flywheel are the same. The throw out bearing is different.

|

|

Do you know why Spec (as an example) lists different part numbers for the 4-speed vs. 5-speed? I guess I could ask them.

I was also wondering if the clutch release fingers are at the same distance from the flywheel regardless of 4-speed vs. 5-speed.

The throw-out bearing is on my transmission, so I expect to keep that.

| quote | Originally posted by Will:

Interested in a dual disk 7.25"? |

|

I'm not really sure what that involves. If I sift through your build thread "The Mule rides again (sort of) - pics." will I find information on that?

This is my wishlist of minimum specifications:

410 lb*ft engine torque

50000 km lifespan

Ability to slip the clutch for stop+go traffic

Moment of inertia not critical; shift time (well, synchronization) is slow with my current setup, but I accept that.

I don't know if there exists a solution that satisfies the above wishlist; I have some research to do.

|

|

|

|