|

| 85 Notchie Build (Page 21/23) |

|

zkhennings

|

JAN 21, 10:24 AM

|

|

I put the Fiero away over a month ago, I cleaned it up nice before pushing it to the other driveway and covering it for the winter.

My dad and I were swapping our cars over to snow tires. I convinced him to get a set of Pilot Sport 4S tires for his summer rims on his stock 2015 Impreza, I wonder if it is the only stock Impreza with those tires. My gold winter wheels and tires can be seen in a stack in the garage.

I put everything away so my parents can park in the garage for the winter. I did remove the engine from the cradle prior to re-installing it and put it back on the stand after taking some measurements. I hope to get to make the alternator bracket for it as well as wrap up other little details so it is ready to go come springtime.

I got my wideband O2 and a gauge installed in the WRX and I have been tuning it constantly. It is pretty fun and I am getting a really good understanding of how the tune works. I may switch to a custom ROM in the near future that would allow speed density tuning, the ROM is based off the Group N rally car ROM. But learning how to dial in the VE table will be very useful for getting the Fiero running. The tuning experience I am getting in general will be really useful for getting the Fiero running well. I had intended for tuning the Fiero to give me the experience I need to tune the WRX, but the tables have turned. The WRX was in a sad state before rebuilding, it had boost issues and was only hitting 9psi, and there was a massive pre-turbo exhaust leak and the motor only made 90psi of compression. With the new bottom end, long tube headers, and having fully gone through the boost lines and then tuning on top of all of that, now I hit 18psi of boost at 3300 rpms and the car is pretty damn fast. I bought a big 18g turbo for it good for 450hp, but I need the Fiero running and driving before I possibly blow the WRX up

I have been spending all my time working on the bus, it has been very cold working long hours outdoors in 20-30* weather, but it will be awesome once the frame is repaired and I can work in the heated interior of the bus.

I bought ten 8' long 2"x3" 11ga rectangular tubing from Metal Supermarket for replacing the crossmembers. Should be really strong and make it much stronger in the event of a rollover. First I am repairing the side frame so I can jack the bus up from the rear to insert the new crossmembers. Here is some repair I have done to the side frame so far.

I just made a build thread for the bus if anyone is interested. Hopefully I get a lot of progress done and am able to use it before the end of the snowboarding season. Once the frame repair is done I will bring my welder back to my parents and work on Fiero fab.

Also I have gone snowboarding 5 days now and my knee feels better and better every time. Tearing my ACL has been a rough journey but the Fiero is almost ready to go which would have never happened had I not torn it, and now my knee is doing great and I am feeling good. Tomorrow is 9 months post-op and my ACL should officially be fused to my bones again. My PT told me that the soft tissue doesn't fully heal from the surgery until a full year out, so I still have a little ways to go before it is 100%, but it feels 90% right now.

Hopefully I finish up the bus frame within the next month and can post an update of working on the Fiero's alternator bracket.

|

|

|

zkhennings

|

MAR 29, 12:17 PM

|

|

No Fiero progress to report but a mini update.

Been working on the bus and the side framing is all repaired, about to finally put in new cross bracing. I need to figure out a good solution for body mounts, I may also forgo them altogether and bolt frame rails right to crossmembers. I have seen older busses built that way, and I am not going to have a ton of passengers in need of comfort like an actual bus. But if you have any recommendations let me know, I have found some poly body mounts for a jeep, they need to be ~2" diameter and Ideally around an inch thick, but I have only found ones 1/2" thick.

My parents house flooded while they were away when the boiler fried and some pipes froze. It was a big problem as the leaks were all the way in the top floor and it still flooded the basement. It is currently an unusable space to work on things. I am honestly tired of working at my parents so I am trying to locate a shop space in northern MA/southern NH area that I will split with a few friends. It is a good time to do it now because I had to box all my car stuff up anyways for the garage and basement to be repaired. Hopefully I can do a couple brake jobs a month to offset the costs of renting a space. The other benefit is I will probably have an indoor space to work on the bus instead of an apartment driveway in the city which will be really nice.

I have been tuning the WRX for a few months now and I have gotten pretty decent at it, I have made it pretty quick and really tuned it to feel how I want it to feel. I have gotten comfortable tuning the fueling, timing, and boost. I have increased stock boost from around 13.5PSI to 20PSI and it has responded very well to the changes after extensive logging and tuning. I have bigger fuel injectors and some other parts to throw into it that I will have to tune for, just trying to gain some experience before getting the Fiero running, but it now seems like it will be a very simple task. I also cannot wait to tune with Tuner Studio with the MS because I have been opensource tuning the WRX and I have to create graphs for all my logs which output as CSVs. I don't have a macro or anything setup so it takes a while and there is no tuning on the fly like with MS. I think it is going to be much more enjoyable tuning the Fiero.

And finally I got in 30 days of snowboarding before partially re-tearing my ACL going off an unexpected drop in the woods. I got an MRI that told me this, and while the doc says I need surgery, the knee feels pretty stable so I am going to try and rehab it without surgery. I was almost a year out from surgery when it re-tore so I don't have a ton of faith in restarting the entire process, especially when I landed the drop fine, knee just was still not strong enough to handle it. And I had been working out 4 days a week, doing yoga twice a week, and snowboarding at least twice a week, so I don't know what I could have done differently to prevent injury other than not snowboard. Been mostly waiting for swelling to go down before starting PT again. And if I get it really strong and it still has issues, I will get surgery and have a much better starting point with a strong knee. I'm gonna be really bummed if I miss a second season of motocross in a row, hoping to just miss half the season, hoping a good 3 months of rehabbing will let it heal up to better than where it was when I re-tore it.

Hopefully find a workshop space in the near future and get all my belongings transported there and can get cracking on the Fiero.

|

|

|

zkhennings

|

AUG 08, 11:26 AM

|

|

Mini update:

Have not touched the Fiero since last year, I have been focusing 100% of my efforts on the bus to get it drivable by the end of August because we are moving out of our apartment and into our new house!

The new house has a 700sqft detached garage/barn and it will be perfect to work on the Fiero in. I am normally working at my parents house and I have to drive there, set up all my tools, do my work, then pack everything up every day before leaving.

Now I will be able to cruise through projects and work late into the night without disturbing anybody, so I am beyond excited.

At the end of August I will hopefully be driving the bus to the new house (And not tow it) but we will not actually be living there until the first of October. I will be living at my parents house in the meantime, and with no bus to work on I plan on making progress on the Fiero starting in September.

Here is the bus currently LMAO wish me luck

Probably going to take a week off to bang the rest of this out. It is closer than it looks to being structurally sound, it is ready to accept the new crossbeams and the frame is almost all prepped, just have a few more reinforcing plates to weld over the last remaining thin spots.

|

|

|

zkhennings

|

NOV 08, 04:24 PM

|

|

Bus got finished enough to drive to CT, threw the walls, windows, and a makeshift plywood floor in it to load it up and make the drive without getting pulled over.

Unfortunately things did not go to plan while living at my parents for the month of Sept, they were getting their kitchen re-done and it was supposed to be wrapped up before we stayed there. And it was not even close, resulting in a garage full of kitchen crap and a sad Fiero.

Fast forward to October first and we moved into our new place, the barn is awesome. But I really wanted to finish up the bus in CT and use all my free time to get that done and get it up to NH.

Fast forward to now and the bus frame was completed and painted, the chassis extended, and the bus made the almost 3 hour drive up to NH.

It was a lot of work and I am glad to be done with it. On the bright side, I have 0 fear of making my own subframes and suspension for the Fiero now.

I also drove down to NY and grabbed this Bendpak 6000 lift that I need to recess into the floor of the barn, but it will be so useful for working on my vehicles. Got a killer deal on it. Lifts up to 47".

Now that the bus frame is done and it is up at my house, I am making moves to get the Fiero up there to finish it up over the winter. Going to borrow a buddy's truck and rent a uhaul trailer to get it done, if not this week then definitely next week! Writing it here to stay accountable and get it done, it has been way too long. But glad the bus is in a great spot to be usable this winter, it needed an insane amount of work and would have never gotten done if my focus was split.

Stay tuned for real this time.

|

|

|

zkhennings

|

DEC 11, 09:53 PM

|

|

|

|

La fiera

|

DEC 14, 07:11 PM

|

|

That's the same one I got! The gear ratio is awesome specially in 3rd and 4th! There is a Quaife limited slip differential available for it, I got one in mine.

[This message has been edited by La fiera (edited 12-14-2022).]

|

|

|

zkhennings

|

DEC 14, 11:16 PM

|

|

I definitely want to get a Quaife for it, and I hope the engine likes to rev out to take advantage of the shorter gears.

Gotta remember to grab the clutch from my parents house tomorrow, was one of the few things I forgot to grab. Going to put the motor back on the cradle and hopefully keep it there. Might check my pressure plate clearances to the F23 too before mating to the Isuzu so I know if I need to order a new clutch for it. I have a feeling it will fit, seems like most of the SPEC clutches do.

|

|

|

ericjon262

|

JAN 01, 07:17 PM

|

|

|

Glad to see you got the car back, any recent updates? ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

zkhennings

|

JAN 02, 10:47 AM

|

|

Indeed, I had to spend a lot of time organizing the barn and getting stuff out of there that wasn’t necessary and I designed some shelving and whatnot that I have yet to build. I also got a heating solution set up and got some propane tanks to run it. And then I started doing some work on the car. I pulled the subframe out, cleaned up the flywheel on the motor as it had gotten some surface rust, cleaned and remounted the clutch, got the throwout bearing installed and mated the engine and trans for what should be the last time.

I then spent time planning what I want to do with alternator, exhaust, and fuel lines. For the exhaust I have decided to have the manifolds point towards the front of the motor instead of having a crossover over the transmission like I had been planning. I am going to notch the new crossmember and have the exhaust pass between the oil pan and motor mount, and it will have a Y right before the cradle hump that allows the exhaust to exit to the muffler. This should allow me to make better headers that will be easier to fabricate, get the exhaust away from the shifter cables, and it will make it really easy to remove from below.

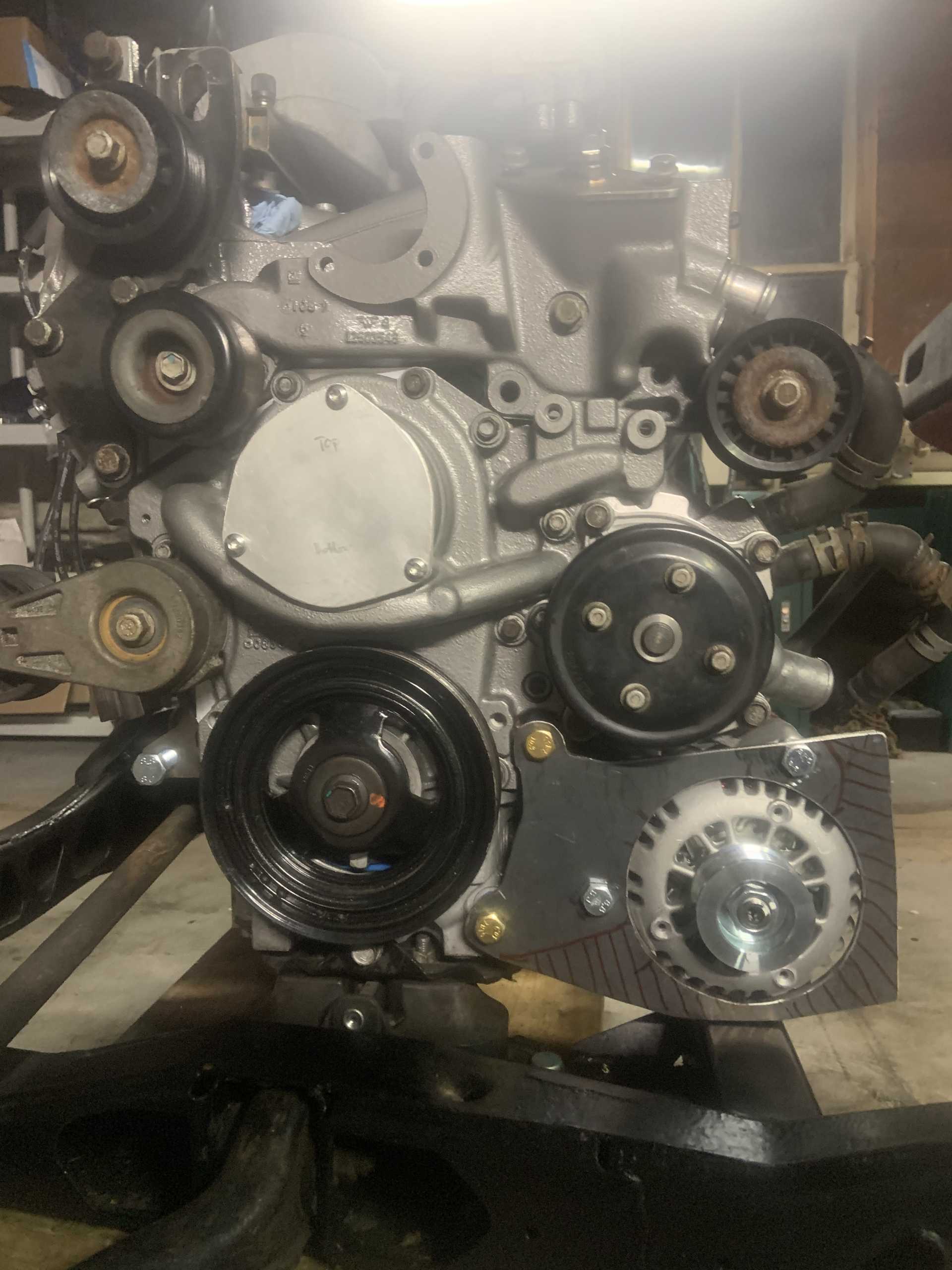

For the alternator I ended up deciding it will go where I have been planning, under the water pump.

I have decided to run the fuel pressure regulator to the drivers side hinge box area, which will make a much shorter run of braided line to get to the fuel rail. Since the exhaust is not going to be over there anymore, it makes much more sense to put it closer to the fuel rail input. It’s much less busy over there.

I bought some 1/4” metal for the alternator bracket and working on that next.

I have also been doing some research to try and figure out a ballpark hp number for this thing. These LZ9 heads have really good flow, with my cam and the 1.7 ratio rockers, it will have almost 0.600" of lift on the intake and a little less than that on the exhaust side of things. Combine that with the port work (especially in the intake and exhaust bowls) and I think I should have very good flow, maybe even close to 300cfm on the intake side. Combined with some good headers I think I could realistically see 300+whp, and I will definitely get it on a dyno to find out. Also want to get a 1/4 mile time on the list and maybe take the spot for fastest NA V6 (or at least fastest NA pushrod 60* V6)

Something else I want to explore is upgrading the trunions in the LZ9 rocker arms, currently needle bearings, these are known to fail in the similarly designed LS motors, especially with higher RPMs. I am very curious if they could be rebuilt with brass bushing trunions for LS rocker arms. With all the other LS components that have fit this motor, I would imagine that they will work, but I am not sure if the OD of the trunion will match the LZ9 pedestal. I may have to get a spare rocker arm and see if I can buy a single trunion upgrade to figure out feasibility. I did some searching but came up with nothing.[This message has been edited by zkhennings (edited 01-02-2023).]

|

|

|

zkhennings

|

JAN 23, 09:54 AM

|

|

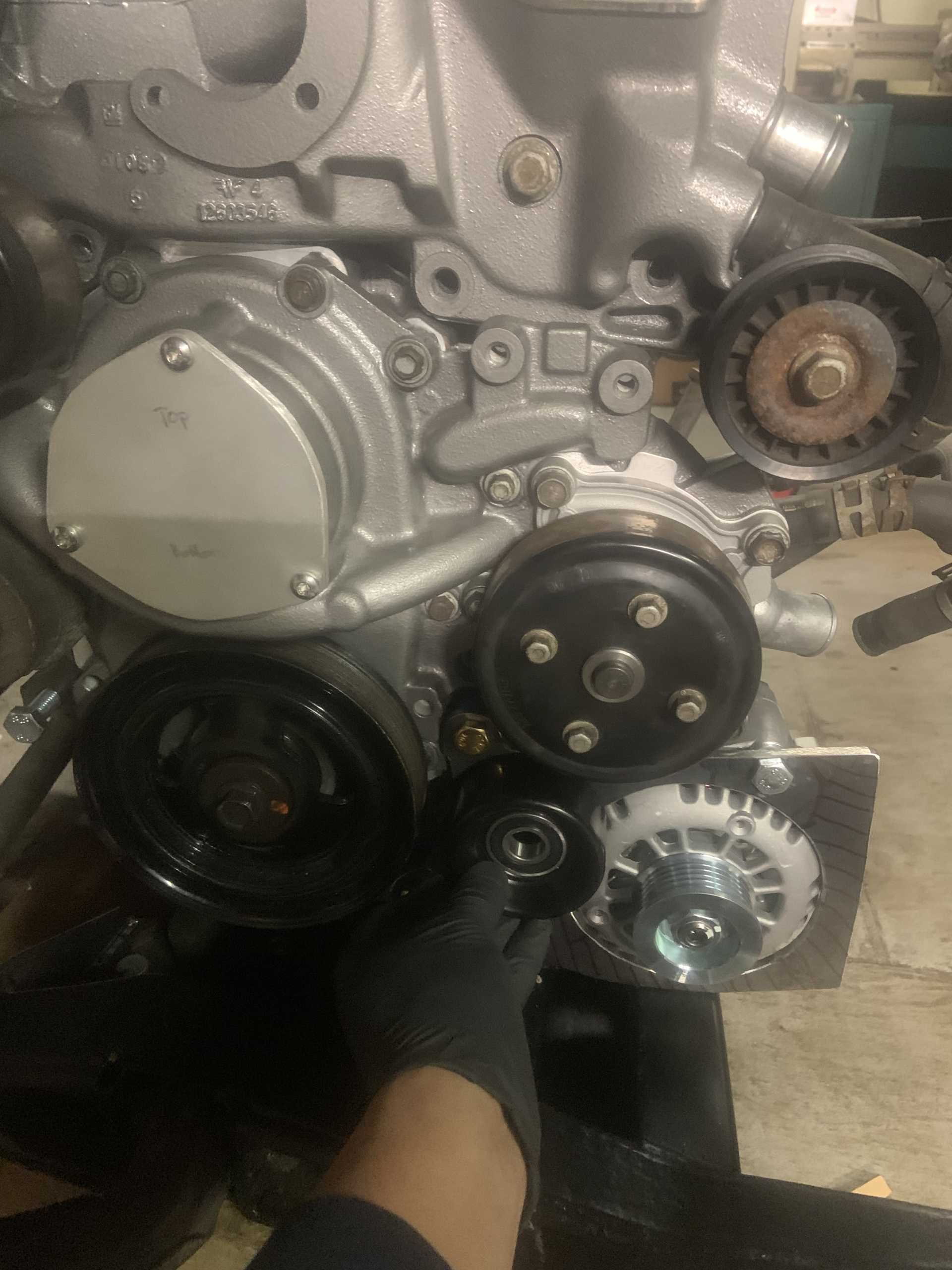

Got some time to mount the alternator.

Did "CAD" to rough out a shape, cut the large circular hole with a jig saw, took forever. I left the bracket as large as possible first to help me figure out all my possibilities.

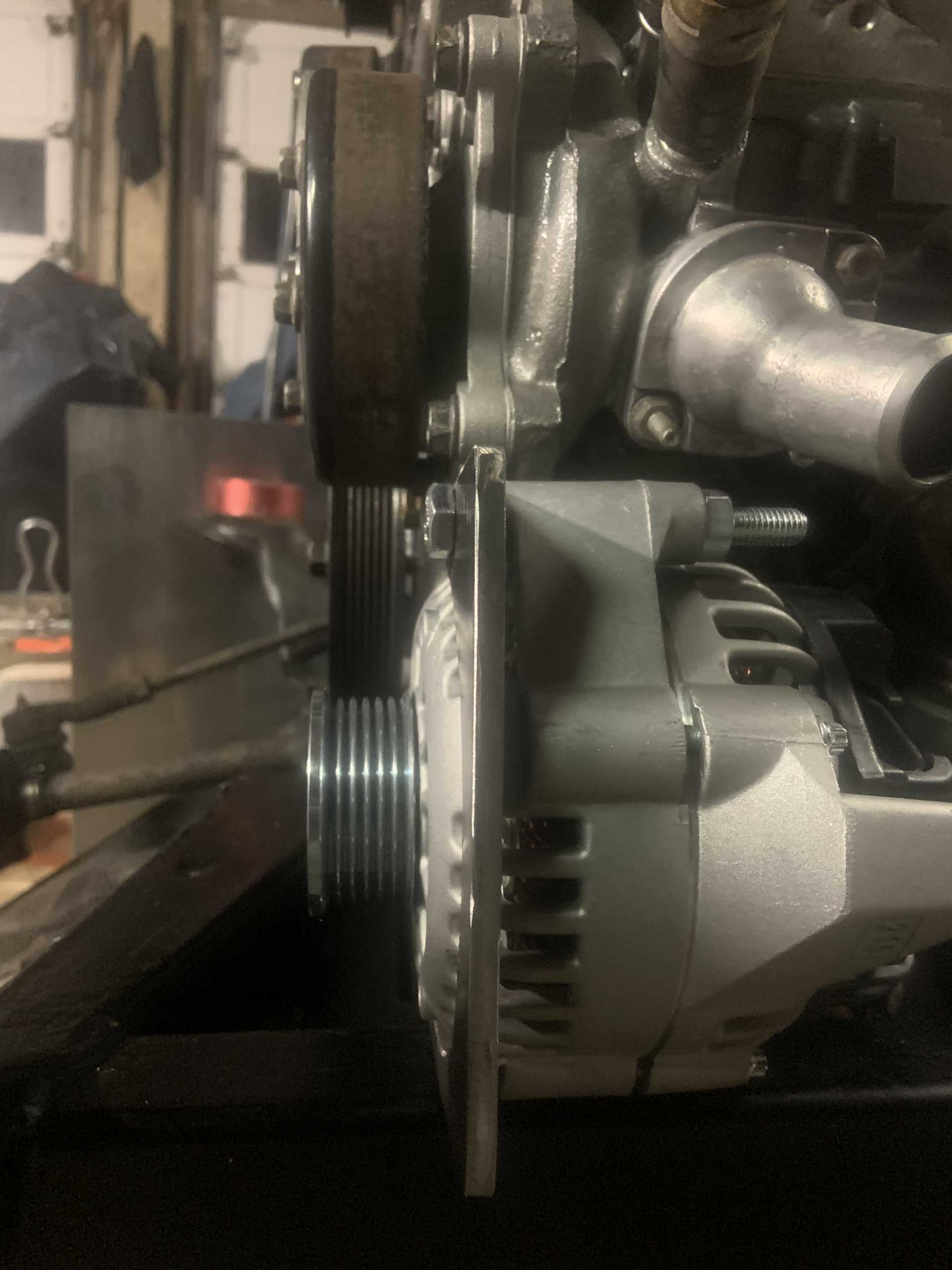

Just using a ton of washers right now to get the spacing correct for the alternator, the two bolt holes I am tying into on the block/oil pan are originally for the AC compressor. I thought they were in the same plane but they are not, the threaded hole in the oil pan is deeper than the hole in the block. I have it spaced out by 2 additional washers right now, but I am going to have to come up with a way to measure the difference precisely.

Not enough clearance to the crossmember for my liking. Engine will only pitch this direction mainly in engine braking, but I don't want them to hit.

Location of idler pulley to maximize belt wrap on the alternator. The spacing is such that the idler pulley will be above all the bolt heads so I have a good amount of freedom on where I put it.

Decided the rear needed to be braced.

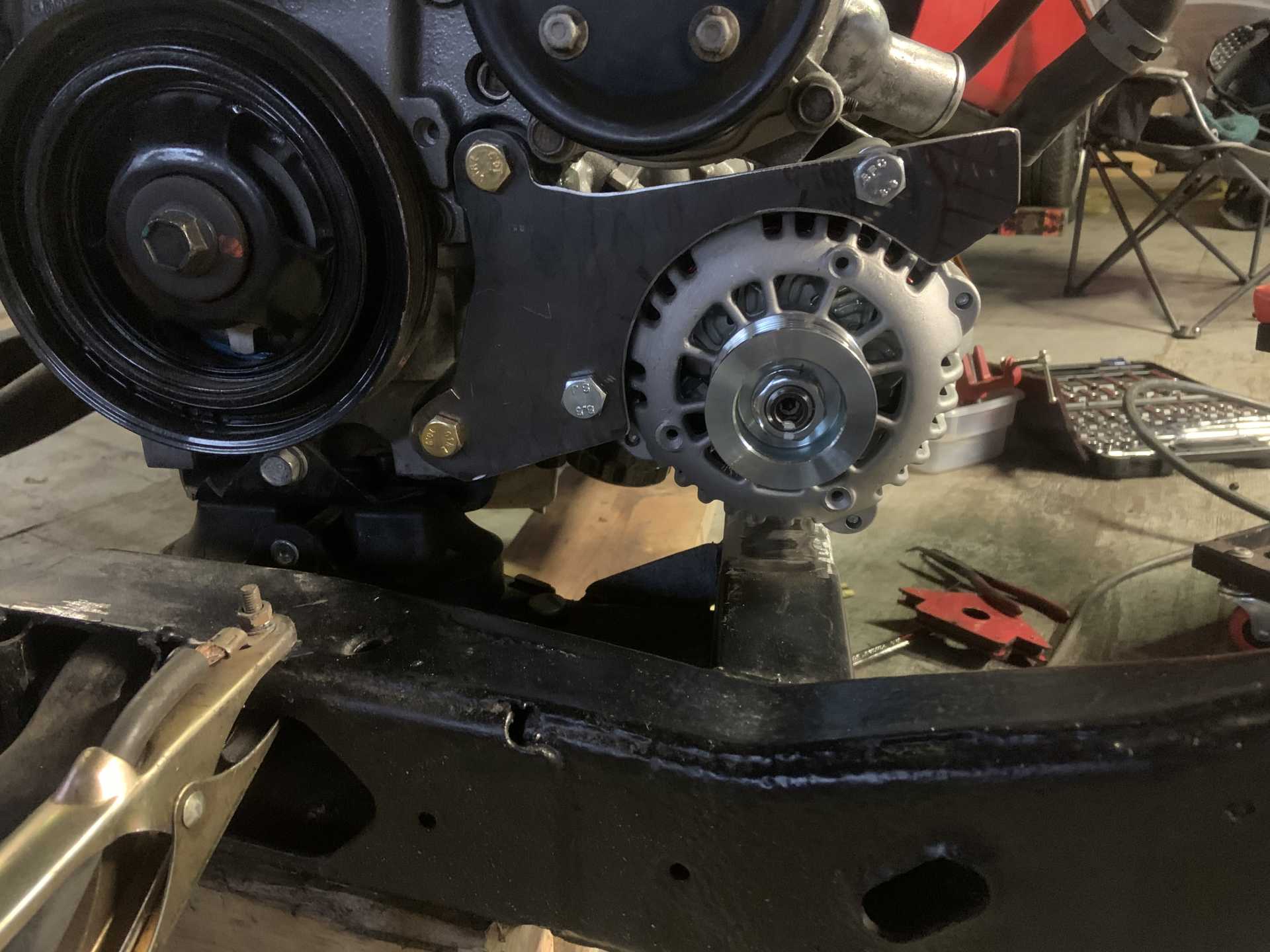

Trimmed the main bracket and fully welded the rear support.

Made a notch in the crossmember for clearance.

And I painted it.

Still have to mount the idler, and make actual spacers with some steel round stock, as well as do some more trimming of the main mount. I had sized the mount originally to be able to bolt on flush, this required me to give it more clearance to the water pump than it actually needs at the spacing that it is at. I may send out to have on laser cut to a more precise shape, or I may just cut another one out by hand. At the same time the current iteration feels plenty strong so I may just leave it.

This was the last bit of major fab required, this took a couple full days, and I did not want to reinstall the cradle until this was done. It is still not done but most of the way there. Before reinstalling the cradle I want to get the fuel lines ran and fuel pressure regulator installed, the battery box made and mounted, and run the stock wiring C500 to get it ready to splice into the Microsquirt harness.

|

|

|

|