|

| The White Bug (Page 20/46) |

|

Will

|

JUL 18, 04:36 PM

|

|

| quote | Originally posted by pmbrunelle:

oil puddle (does this happen?) above the ball.

What's better? Grooved or smooth? |

|

See my post above yours... Pre-oil and engine with stock rockers and oil will DEFINITELY pool in the rocker arms, immersing the rocker ball in oil.

|

|

|

pmbrunelle

|

JUL 18, 04:46 PM

|

|

| quote | Originally posted by Will:

See my post above yours... Pre-oil and engine with stock rockers and oil will DEFINITELY pool in the rocker arms, immersing the rocker ball in oil. |

|

I saw that now. I didn't see your last post when I was writing my previous message.

|

|

|

fieroguru

|

JUL 18, 05:53 PM

|

|

If you start the car when cool and let it run w/o the valve cover off, it will confirm what the issue is before the exhaust manifolds start getting too hot. You could install a shield over the exhaust if you wanted an extra safety. It is pretty cool to see the rockers in motion at idle and some issues are very obvious, like this one...

|

|

|

La fiera

|

JUL 19, 09:15 PM

|

|

|

Another approach you can try is to slot or elongate the hole torwards the ball. By doing this the velocity of the oil from the pushrods will decrease at the rocker oil hole because it's bigger. Oil at lower velocity will not fly off missing the ball but spew like a volcano filling the rocker bowl with oil.

|

|

|

pmbrunelle

|

JUL 26, 12:27 AM

|

|

I put the engine back together with stock replacement Melling MRK-407 rocker arms and smooth (non-grooved) pivot balls. The Melling rocker has its oil hole oriented towards the rocker stud.

So the engine is running again, and it sounds normal.

Two questions remain:

1. Will the pivot balls live this time? I will find out by driving the car.

2. Will this engine breathe less well, because the stamped rocker may have less consistent (i.e. lower) ratios? My WOT tune was pretty good (hitting the AFR target) with the Comp Cams rockers. With the stamped rockers, if the engine runs richer than before at WOT, that means that the engine isn't breathing as much air as it did before. I will check this shortly.

I think that I want solid lifters (either roller or flat tappet) for my next project. Hydraulic lifters are a huge PITA in the sense that it's hard to verify valvetrain operation with the engine off. Solid lifters work the same with or without oil pressure.[This message has been edited by pmbrunelle (edited 07-26-2020).]

|

|

|

Will

|

JUL 26, 11:32 AM

|

|

|

If you go solid, go solid roller... fewer valve adjustments required down the road.

|

|

|

pmbrunelle

|

JUL 26, 05:38 PM

|

|

In order to meet the AFR target, I cut the fueling:

1% @ 5500 RPM

4% @ 6000 RPM

I am slightly disappointed, but a reliable (still to be proven) engine beats a better-breathing engine with a lifespan of a several hundred kilometres!

|

|

|

La fiera

|

JUL 26, 10:31 PM

|

|

If you are going to use solid lifters use these;

http://schneidercams.com/SOLIDlifter5206-12.aspx

The advantage of these is that they have a tiny hole (.024) that delivers pressurized oil between the lobe and the lifter to keept the cam lobe and lifter always lubricated. I've always used these in my Supernatural engines and cams look like new. Every time I check the lash is on point. They are not dependant on splash oil, the are pressured fed.

|

|

|

pmbrunelle

|

AUG 09, 10:40 PM

|

|

I started to experiment with the boost control solenoid yesterday.

With the wastegate spring alone, MAP is around 150 kPa.

I finally enabled the boost control feature of the MS3, and I increased the MAP to about 175 kPa. Now the injectors are really maxed out (94% duty cycle observed).

I then went to the dragstrip to see what it would do:

https://www.youtube.com/watch?v=sucaTBVG6K4

The timing equipment seems to be in disrepair (timeslips missing information), so I didn't get too much value from that dragstrip evening...

On the butt dyno, the boost increase didn't seem to increase performance very much. I think that's because I was retarding the ignition timing too much with boost. I uploaded a new ignition timing table with less boost retard to the car.

I also advanced the ignition timing in the 5000 to 6000 RPM range, since the engine is breathing less well in this range. A less dense air-fuel mixture (and therefore a slower-moving flame) needs to be ignited earlier to perform the most work on the piston. I looked at the VE table for indications on how to do this.

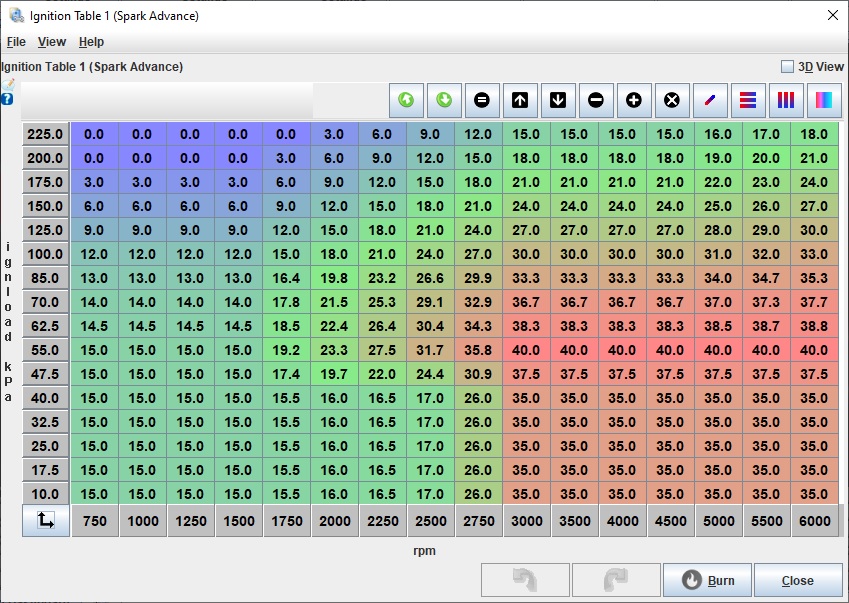

Here is the revised ignition table I just loaded into the car:

There have been many revisions. This is is certainly not the last!

You will notice that at low loads, the timing is quite retarded relative to MBT.

The car used to have a bucking sensation at low loads below 2500 RPM... driving with more throttle would eliminate that, but I did want to be able to drive calmly and smoothly.

Retarding the timing at low loads cured that problem. I am not certain of the root cause, but I do have my suspicions.

Apparently the bucking is something that happens when people install aggressive cams; too much exhaust gas remains from the previous cycle and dilutes the air-fuel charge. Maybe by retarding the timing, the cylinder pressure is higher at the moment the exhaust valve opens, and the cylinder is scavenged better.

Probably my low 7.4 compression was a factor, leaving room for more exhaust gas to stay inside the cylinder (instead of being pushed out), but the car drives fine now.

Oh, I forgot to add that the stock-style stamped rockers are doing just fine![This message has been edited by pmbrunelle (edited 08-09-2020).]

|

|

|

Honest Don

|

AUG 13, 01:17 AM

|

|

|

Results? At what increment are you advancing timing?

|

|

|