|

| 1987 GT – Rear Struts Do Not Hold Camber Setting (Page 2/2) |

|

Raydar

|

JUL 22, 02:17 PM

|

|

| quote | Originally posted by Brian A:

What IS the torque spec for those nuts??? |

|

I always preferred the "Tighten until it strips, then back off a quarter." method.

...or not.

|

|

|

Brian A

|

JUL 22, 02:50 PM

|

|

| quote | Originally posted by Raydar:

I always preferred the "Tighten until it strips, then back off a quarter." method.

...or not.  |

|

… or use the welder.[This message has been edited by Brian A (edited 07-22-2025).]

|

|

|

fieroguru

|

JUL 22, 05:52 PM

|

|

By definition, bolted joints fail when there is any movement. So I am not a fan of filling the slotted gap or counting on the cam washer to hold it in place.

The old camber bolts had the washer part of the head and they were full diameter M14. They were to hold the camber setting in place until the bolt is torqued. Still have a set on my car.

If you wanted to do anything, you could have a plate cut similar to the 88 sway bar bracket. It is 1/4" thick and covers the side of the strut flange. It helps spread the clamp load further beyond just the area of the bolts.

|

|

|

cartercarbaficionado

|

JUL 22, 05:54 PM

|

|

| quote | Originally posted by Brian A:

I'll be darned. I never questioned the needed torque. Thank you.

I've been cranking on the wrench but have just been using "normal" pressure. It may be that I, and the alignment shop, are just not tightening them enough.

What IS the torque spec for those nuts??? |

|

if you use the later splined hardware from a grand prix (which i just did) i used the 2001 gtp spec which is 135 ft lbs (we have a steel knuckle vs aluminum so you could go to the limit of the bolt there.) so far i havent had a slip except dropping the car off a trailer.... other than that its holding through as aggressive of driving as im comfortable doing without a rear sway bar

|

|

|

pmbrunelle

|

JUL 22, 09:53 PM

|

|

| quote | Originally posted by fieroguru:

By definition, bolted joints fail when there is any movement. So I am not a fan of filling the slotted gap or counting on the cam washer to hold it in place. |

|

I also have this point of view.

********************************************************************************

Once you have the joint tightened up well, you can check for movement afterwards using "anti-sabotage" or "tamper seal" paint:

If you paint this between the strut clamp and the knuckle, it leaves a thick bead. Then, if there is relative movement between both parts, the bead will crack.

You can perform regular visual inspections and easily see if something moved.[This message has been edited by pmbrunelle (edited 07-22-2025).]

|

|

|

cvxjet

|

JUL 22, 11:49 PM

|

|

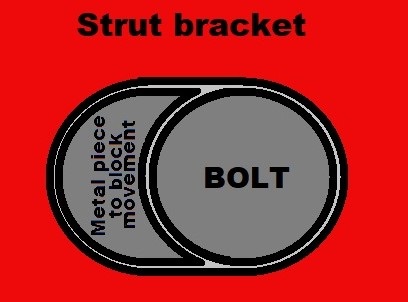

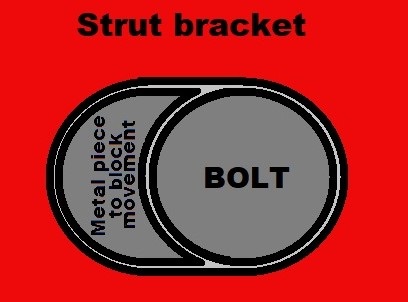

Here is a diagram of what I did with the small piece of metal...

[This message has been edited by cvxjet (edited 07-22-2025).]

|

|

|

Brian A

|

JUL 23, 12:21 AM

|

|

| quote | Originally posted by cvxjet:

Here is a diagram of what I did with the small piece of metal...

|

|

That is what I was thinking too, although it may requirer spacers on both sides of the bolt.

I might actually build them before just trying the higher torque.

|

|

|

Patrick

|

JUL 23, 02:50 AM

|

|

| quote | Originally posted by Brian A:

That is what I was thinking too, although it may require spacers on both sides of the bolt.

|

|

IMO, there's no need to re-invent the wheel. The correct style camber bolt in the lower hole, with the proper torque... and nothing's going to move.

|

|

|

olejoedad

|

JUL 23, 07:16 AM

|

|

The Fiero did NOT come with camber bolts.

The purpose of a camber bolts is to allow the alignment tech to more easily set the camber without help from another mechanic.

It is a labor saving device - that is it's sole purpose![This message has been edited by olejoedad (edited 07-23-2025).]

|

|

|