|

| How does ECU know if Manual or Automatic Transmission is Used (Page 2/3) |

|

Mickey_Moose

|

NOV 26, 08:28 AM

|

|

link repaired in original post - sorry about that

Everything is in the EPROMS files\others directory, EPROMS are relatively cheap, but are getting harder to find, there are still a few places as there is still a high demand for them in the "retro" hobbies.

The only files you needs are the EPROM - the smaller chip are all the same as mentioned above contains the limp mode tables.

Oh, and thanks for your link, wish I had that a few months ago.  lol lol[This message has been edited by Mickey_Moose (edited 11-26-2024).]

|

|

|

Romsk

|

NOV 26, 07:42 PM

|

|

Raydar,

Thanks for the info. So the CALPACK has the Limp Home parameters... good to know.

Yes, that would be interesting if the engine could run without a PROM at all. My thoughts... all the ECU has to do is put the EST ICM in bypass mode and pulse the Injectors when the EST signal comes in from the Distributor, and using the TPS to widen the Injector pulse depending on its position. Pretty much a fancy carburetor at that point. Since all 6 Injectors are pulsed at once to better atomize the fuel at each intake port (learned that at this site), no Injector cylinder timing is needed... another reason why all Injectors pulse at once... an eaiser fail safe (limp home) mode.

A simple hardware circuit can do all that with no computer control at all.

I think it is high time for me to get schematics of the ECU and source code for the PROM. They use a 68HC11 microcontroller as the CPU. I wrote 68HC11 assembly code when I was a young pup engineer in the late 1980's. It can't be all that difficult compared to missile system I have helpec designed back then.

Can anyone point me in the right direction?

|

|

|

Romsk

|

NOV 26, 07:47 PM

|

|

Micky_Moose

Great web site. I download the APR for my old ECM and the APN for my existing GT ECM.

Thanks!

Would you mind if I posted a link to your page in my web page?

|

|

|

Romsk

|

NOV 26, 08:08 PM

|

|

Raydar,

These PROMs can become temperature sensitive?... well they are 40 years old and that memory technology is approaching 45 years or so now.

We are on the forefront of witnessing this technology in one of it its widest, oldest, and stil living applications.

My Fiero would start but once it warmed up near operating temperature, if I stopped it and then restarted it a few minutes later, it REFUSED to start. I would have to wait 15 to 30 minutes before it would re-start. This happened at a gas station. It probably was having this problem for a couple of week, but since I was driving it only to work and then home at the time, I never saw it because the car had hours between starts... I was filling up every two weeks and gas was the only place I stopped to/from work.

I guess the ECU has a fail safe to prevent the Engine from starting if it has been running for a while, stopped, and CTS is though the roof. The ECU must have some way of knowing

it was off long enough to be safe to start... because the CTS resistance was wide open hot or cold. My SES light was not working at time, I found that to be a loose connection on the Instrument Cluster connector.

I connected my car to the Fiero GT ALDL Monitor tool that I designed, put it DMDIAG Mode, and saw in seconds that my IAT (MAT) and CTS were reading at the end of their scales after sitting all night at around 70 degrees F. I replaced them both and I was running normally again.

|

|

|

Romsk

|

NOV 26, 09:33 PM

|

|

Raydar,

You said the SES lamp was blinking rapidly when your ECU/PROM got hot, correct?

We all know the SES lamp comes on steady in Normal Mode (no resistance or shorting on pins A and B on the ALDL Connector) when a Error Code is thrown.

But I think I remember reading somewhere (the owners manual?) that a flashing SES lamp means shut down the engine now. Correct?

That SES lamp tells us a lot:

NORMAL Mode (what users can get):

Off: No Errror Codes, nothing bad detected but there may be issues building.

Steady on: Service Engine Soon, check Error Codes.

Blinking: Shut down Engine NOW.

DMALDL Mode:

Need to confirm this.

I think it is off in this mode.

Other: Not sure yet.

DMFACT Mode:

Need to confirm the lamp function in this mode.

This mode puts the ECM in Limp Home Mode to test that Fail Safe Circuitry.

I forget what the SES lamp does. I think it is on in this mode.

DMDIAG Mode:

Ignition On, Engine Not Running: Blinks Error Codes.

Engine Running:

Blinking Rapidly: ECU is in Open Loop.

Blinking Slower: ECU is in Closed Loop. On when the O2 level is slightly Rich (AFR just under 14.7 to about 14.5), Off when slightly Lean (AFR from just over 14.7 to about 14.9).

Because a Narrow Band O2 Sensor is used, the ECU constantly adjust the Air Fuel Ratio slightly above and below the Stoichiometric midpoint of 14.7 : 1 as a running check to make sure the O2 sensor is working properly and responding quickly to AFR changes (it does this all the time, even in NORMAL Mode, but we never feel it because it is a slight AFR change but the O2 Senor swings the most volts in this narrow range).

It should blink about every second or so and it should go above (light on) and below (light off) 50% of the time... it varies, but on average a 1Hz 50% Duty Cycle blink rate.

Not too shabby for a light most people think is just an "Idiot Light" [smile].

|

|

|

Mickey_Moose

|

NOV 29, 11:39 AM

|

|

| quote | Originally posted by Romsk:

Micky_Moose

Great web site. I download the APR for my old ECM and the APN for my existing GT ECM.

Thanks!

Would you mind if I posted a link to your page in my web page? |

|

Hi, glad it was of some use. Feel free to post a link (not really a "page" just a google drive directory that can be shared).  lol lol

edit: saw in your other post, I may have a copy of the ECM schematic as well. I will have to look for that - but in my head I seem to think that I have a copy of that.  [This message has been edited by Mickey_Moose (edited 11-29-2024).]

|

|

|

Dennis LaGrua

|

DEC 05, 10:12 PM

|

|

| quote | Originally posted by Romsk:

82-TA [At Work].

The 85 V6 had provisions for a Knock Sensor. You mean the 1226869 ECU has an input pin for a Knock Sensor? |

|

You just need to add the sensor, the GM ESC module, wire it to the ECM, reprogram to accept knock inputs and you have knock control. I did this on my turbo 3.4L and it works like a charm but ONLY with the1226869 ECM that was used in 85.

------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Mickey_Moose

|

DEC 08, 10:31 AM

|

|

| quote | Originally posted by Romsk:

I think it is high time for me to get schematics of the ECU and source code for the PROM. They use a 68HC11 microcontroller as the CPU. I wrote 68HC11 assembly code when I was a young pup engineer in the late 1980's. It can't be all that difficult compared to missile system I have helpec designed back then.

|

|

I finally found what I have for the 7170 schematics - uploaded to the google drive posted earlier.  [This message has been edited by Mickey_Moose (edited 12-08-2024).]

|

|

|

Romsk

|

DEC 29, 10:24 PM

|

|

Mickey_Moose

Thanks for the info.

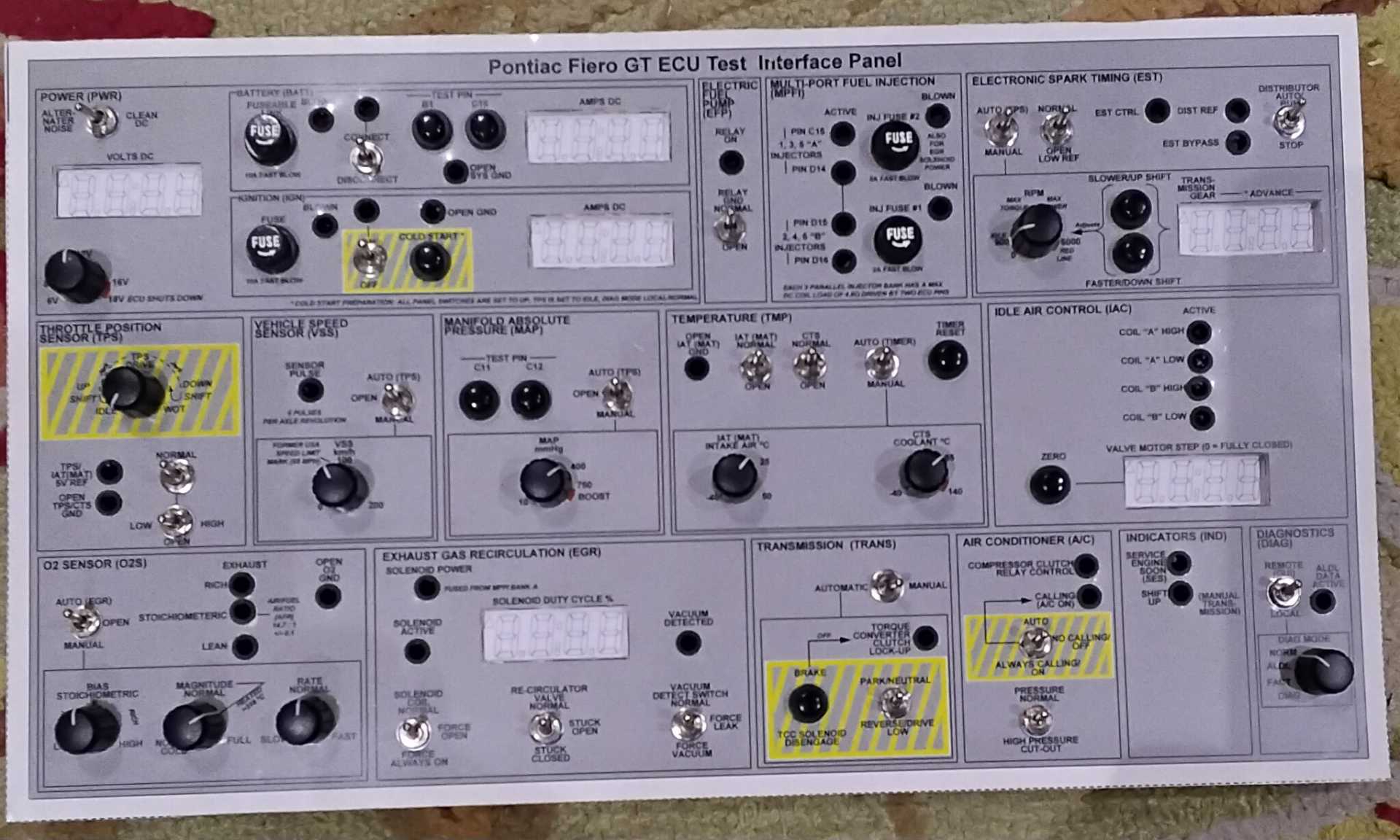

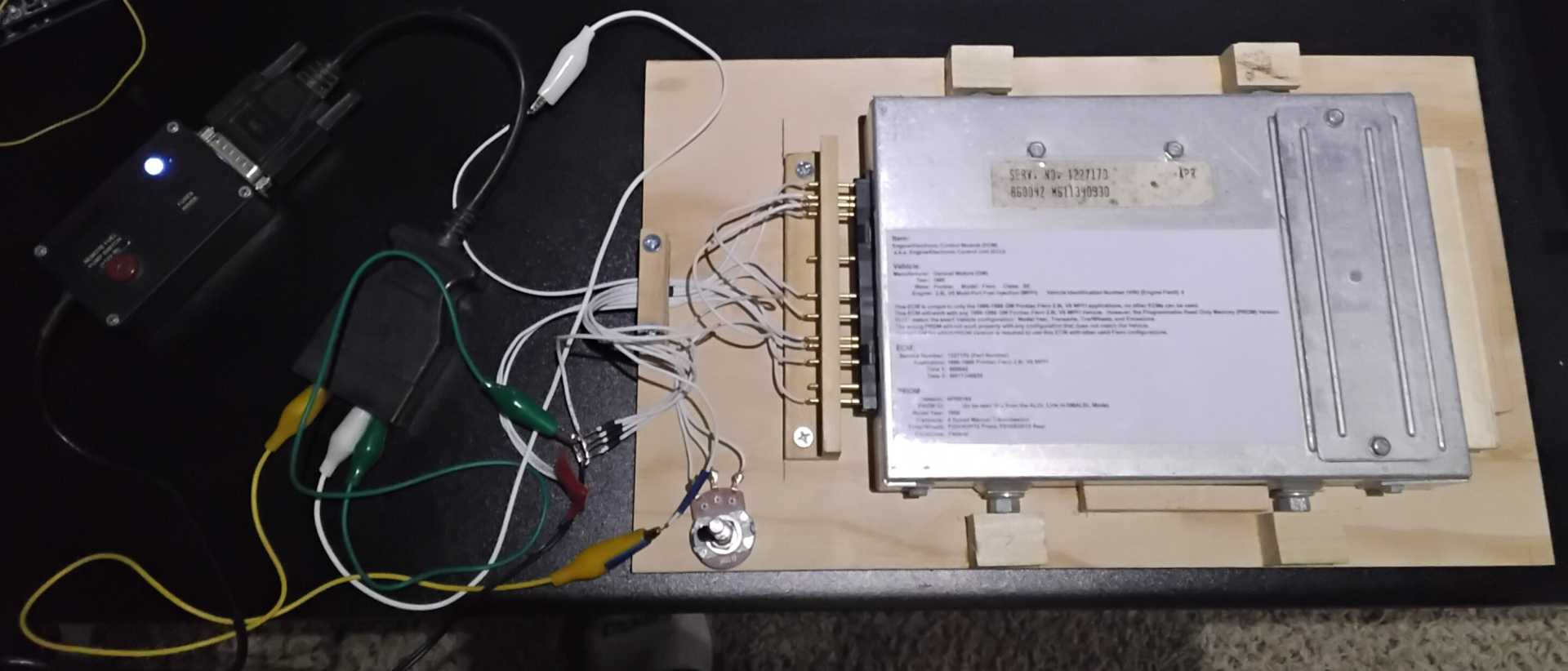

My ECU Bench Tester is coming along. I have been ordering parts here and there for the control panel. I went to Staples and they printed out the panel 1:1 scale on 11x17 photographic paper with ink that is smudge proof. I glued it to high quality thin plywood. I still have to order LEDs and the LCD displays. I tried it with just the TPS pot and my ALDL Adapter connected to my spare ECU. So far it works and only throws an error code for the MAP sensor. When I get all the inputs and outputs wired, it should work.

------------------

Paul Romsky

|

|

|

Patrick

|

DEC 29, 11:22 PM

|

|

Looks pretty cool!

|

|

|

|