|

| F40 Shifting mechanism? (Page 2/2) |

|

Will

|

MAR 21, 06:53 AM

|

|

| quote | Originally posted by pmbrunelle:

By cutting off the air supply as the shift rail reaches neutral (see the importance of position feedback as already mentioned), it is enough to prevent going to the other side, in conjunction with the detent. I did study the possibility of discrete three-state rail position sensors, but it was preferred to use rail position sensors with a continuous reading.

...

I don't know how things could/should be with hydraulic actuators.

********************************************************************************

The clutch is much more position-controlled, and not force-controlled.

This lends itself more to hydraulics, or an electric motor + ballscrew. Continuous position feedback is really needed here.

|

|

The pulse width to the air cylinder has to be tuned in order not to over-shift the transmission and bump the synchro on the other side. That's probably simpler than tuning hydraulics to do the job, but still requires tuning.

With a solenoid, you'd just hit the juice until the end-point switch closes

Anti-lock and stability control functions have been pumping up high brake fluid pressure without any pedal force for thirty five years or more. Adapting one of those systems to operate a clutch shouldn't be so difficult. A position sensor and a PWM solenoid (like the ones used as isolation & dump valves on ABS systems) should handle the job with some tuning.[This message has been edited by Will (edited 03-22-2022).]

|

|

|

pmbrunelle

|

MAR 22, 11:05 AM

|

|

| quote | Originally posted by Will:

The pulse width to the air cylinder has to be tuned in order not to over-shift the transmission and bump the synchro on the other side.

|

|

I wasn't in the project anymore, but I heard colleagues constantly discussing/characterizing mass flow rate in and out of the cylinder for a solid 6 months ~ 1 year to avoid that issue.

********************************************************************************

Thinking about it some more, an F40 direct-acting actuator retrofit would likely place the actuators in-line with the shift rails, which would then run into the LH lower frame rail of the Fiero.

Since the automotive problem is one of packaging, the XY solution might work better for that reason.

|

|

|

Will

|

MAR 23, 07:42 AM

|

|

A Muncie has a single shift rail on which all shift forks are free sliding. Actuators would not be able to work on an individual rail because the design does not allow for that.

A Getrag has FOUR shift rails (1/2, 3/4, 5, R) to which shift forks are pinned. Actuators COULD work on each rail, but as you noted would interfere with the Fiero frame rail if mounted co-axially. The actuators would need to work via rocker arms like a valvetrain in order to operate the shift forks.

An F40 has two shift rails (1/2 & 5/6, 3/4 & R, I *think*) with free sliding shift forks, so an actuator per rail would not work.

|

|

|

Will

|

MAR 24, 10:57 AM

|

|

| quote | Originally posted by pmbrunelle:

On the Eaton Endurant,

|

|

I looked up the Eaton Endurant and read some of the marketing materials. It occurred to me that the heavy duty sector mates up engines and transmissions from different manufacturers all the time. There are standardized SAE bellhousings to make this easier.

Is there also a standardized bus specification that lets the controllers talk or is each combination an exercise in bus integration?

|

|

|

pmbrunelle

|

MAR 24, 12:15 PM

|

|

All sensors/actuators on the transmission lead to the transmission control module via bespoke protocols.

The "intelligence" is mostly located inside the TCM, but I don't know how the TCM interfaced to the vehicle. I was an oompa-loompa (among many other people), I just mostly focused on figuring how to get feedback of shift rail positions and send it back to the TCM.

********************************************************************************

Speculating...

SAE J1939 standardizes a lot about CAN bus communication on a vehicle, and also covers different abstraction levels of the OSI model, all the way down to specifying the wiring layout of the bus itself.

Truckers are pretty keen on SAE J1939, so if J1939 happens to specify how to handle throttle lift/blip, I bet they would follow J1939.

SAE J1939 is a pretty gigantic standard; its different sections are sold separately. I'll have a quick look in the afternoon to see if any of the sections we have at work happen to cover the engine-transmission interface.[This message has been edited by pmbrunelle (edited 03-24-2022).]

|

|

|

pmbrunelle

|

MAR 24, 05:54 PM

|

|

| quote | Originally posted by pmbrunelle:

SAE J1939 is a pretty gigantic standard; its different sections are sold separately. I'll have a quick look in the afternoon to see if any of the sections we have at work happen to cover the engine-transmission interface.

|

|

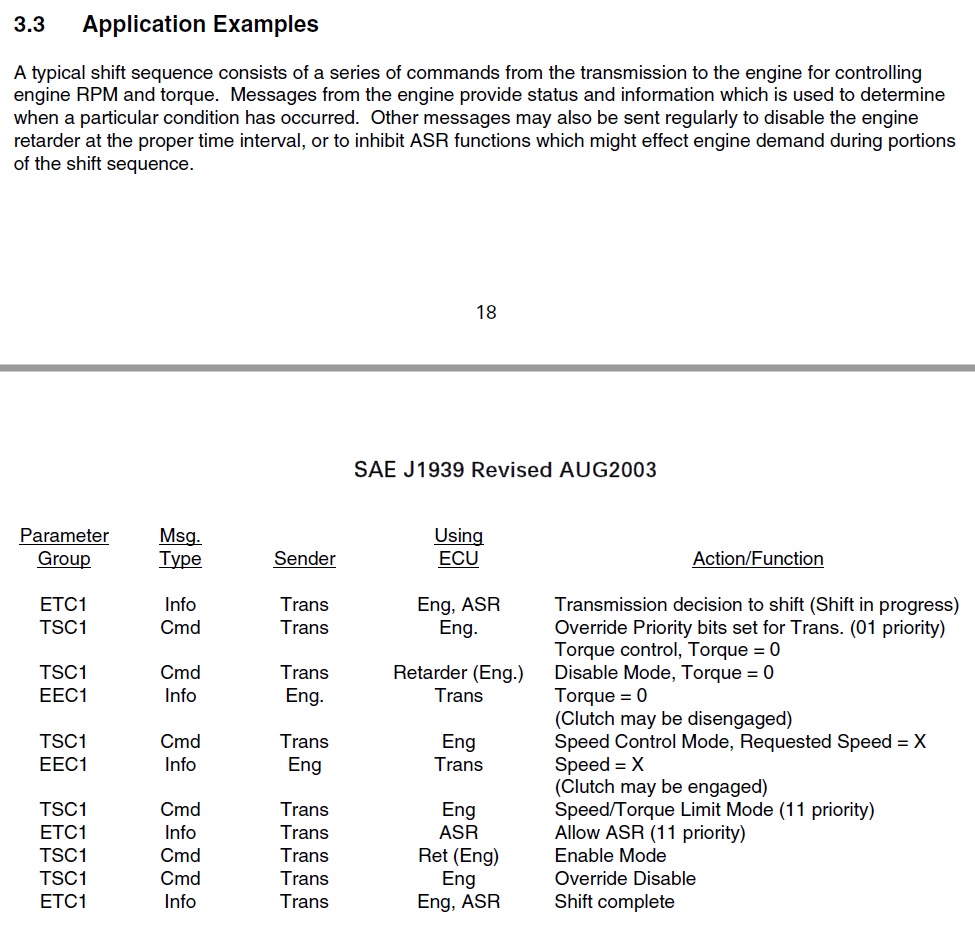

I had a peek in the top-level gateway document.

Looks like J1939 offers a standardized way to interface an engine to a transmission:

[This message has been edited by pmbrunelle (edited 03-24-2022).]

|

|

|

|