|

| Slight Regular Misfire and No Power After Upgrades (Page 2/6) |

|

Imnuts

|

JUL 22, 11:29 AM

|

|

I made the mistake of installing Taylor spark plug wires during an engine rebuild. After months of ruff idling and lack of power I noticed burn marks on my red plug wires. I found almost all had black spots where they touched each other and some where they touched metal. Make sure all wires are isolated or have wire sleeves over them where in close contact.

Wow what a difference it made in power after the fix.

------------------

∇PONTIAC∇

“The difference between a Fiero owner

and a genius is that genius has its limits.”[This message has been edited by Imnuts (edited 07-22-2020).]

|

|

|

Notorio

|

AUG 06, 11:41 PM

|

|

Major Update today ... I've been too busy to do anything with the car so I brought it to a speed shop that also does Smog, since I'm still driving on expired tags. In a one-hour diagnosis to look for a slight misfire he found:

1) Spark OK to all cylinders

2) Compression OK on all cylinders

3) Leak-down test failed on #6 at 35% vs normal of 5% or so.

4) All spark plugs appeared normal except #6 which was fouled with oil

5) Vacuum gauge fluctuations point to incomplete combustion.

Something I forgot to mention to him (and you guys) is that the oil gauge pressure has been running LOWER than before I did anything to the engine, including the high-volume pump. Something else to keep in mind is that #6 has two heli-coils but torqued down just fine.

So WHERE is the oil coming from that is doing the fouling? He suggested:

A) Bottom End. Since I related the story of the terrible misfiring and shaking on first start up due to water in the gas tank, he thought there was a possibility that there might have been an initial hydrolock-like situation which could have bent a rod enough to create the failing leak-down test. So in this case the oil would be coming up from the bottom past the rings, now somewhat tweeked by the bent rod.

B) Top End. Bad valve stem oil seal, damaged valve seat or valve guide. Bent pushrods from using 'stock' rods with the 1.6 roller-tip rockers. He didn't believe me that 'lots of people on the forum have done this upgrade and just use New, standard pushrods'. He said I should have checked for clearance myself ... my bad  . .

So now I have to tear down part of the engine again. I thought I would just bring the Even head to the shop and let him do the measurements, etc. One thing he said I should do is to measure the piston height at TDC on #6, 4, and 2, which would show if the rod has bent. The motor runs too well otherwise so he didn't think I cracked the block (yet.)

To be honest I am very loathe to tear that down and make the car undriveable again after 2 1/2 years of working around the hulk in the garage. At least as it is right now I can move it under its own power. Are there any recommendations out there? Alternative theories??[This message has been edited by Notorio (edited 08-06-2020).]

|

|

|

Patrick

|

AUG 07, 12:09 AM

|

|

| quote | Originally posted by Notorio:

B) Top End. Bad valve stem oil seal, damaged valve seat or valve guide. Bent pushrods from using 'stock' rods with the 1.6 roller-tip rockers. He didn't believe me that 'lots of people on the forum have done this upgrade and just use New, standard pushrods'. He said I should have checked for clearance myself ... my bad  . .

|

|

What "clearance" is he referring to? Valve to piston clearance? Are your pistons stock?

I used new "stock" pushrods when I upgraded to 1.6 roller tip rockers with no issues (original cam). Unless you totally botched up finding zero lash and/or adjusted way too much preload on the lifters, I don't see how "clearance" should've been a problem.

Any chance you damaged an intake valve guide seal during installation?

|

|

|

Notorio

|

AUG 07, 11:14 AM

|

|

| quote | Originally posted by Patrick:

What "clearance" is he referring to? Valve to piston clearance? Are your pistons stock?

I used new "stock" pushrods when I upgraded to 1.6 roller tip rockers with no issues (original cam). Unless you totally botched up finding zero lash and/or adjusted way too much preload on the lifters, I don't see how "clearance" should've been a problem.

Any chance you damaged an intake valve guide seal during installation? |

|

Yes, valve to piston. The pistons are stock (I didn't do anything to the short block other than the new oil pump and timing chain) and I just assumed that the cam was original. It is of course possible that I botched the lash adjustment ... I followed the manual but might have zoned out or gotten distracted perhaps on that valve. Probably it is more likely that I damaged the valve guide seal during installation.

|

|

|

Dennis LaGrua

|

AUG 07, 11:19 AM

|

|

| quote | Originally posted by Notorio:

3) Leak-down test failed on #6 at 35% vs normal of 5% or so.

Something else to keep in mind is that #6 has two heli-coils but torqued down just fine.

So WHERE is the oil coming from that is doing the fouling?

A) Bottom End. Since I related the story of the terrible misfiring and shaking on first start up due to water in the gas tank, he thought there was a possibility that there might have been an initial hydrolock-like situation which could have bent a rod enough to create the failing leak-down test. So in this case the oil would be coming up from the bottom past the rings, now somewhat tweeked by the bent rod.

B) Top End. Bad valve stem oil seal, damaged valve seat or valve guide. Bent pushrods from using 'stock' rods with the 1.6 roller-tip rockers. He didn't believe me that 'lots of people on the forum have done this upgrade and just use New, standard pushrods'. He said I should have checked for clearance myself ... my bad  . .

So now I have to tear down part of the engine again. I thought I would just bring the Even head to the shop and let him do the measurements, etc. One thing he said I should do is to measure the piston height at TDC on #6, 4, and 2, which would show if the rod has bent. The motor runs too well otherwise so he didn't think I cracked the block (yet.)

To be honest I am very loathe to tear that down and make the car undriveable again after 2 1/2 years of working around the hulk in the garage. At least as it is right now I can move it under its own power. Are there any recommendations out there? Alternative theories??

|

|

Its obvious that something is wrong on cylinder #6. You will need to pull the heads and take a look or use a fiber optic camera to look in through the spark plug hole to inspect the cylinder. If the piston to valve clearance is not there you will see marks on the piston tops but interference problems don't normally show up on just one cylinder. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Notorio

|

AUG 09, 05:35 PM

|

|

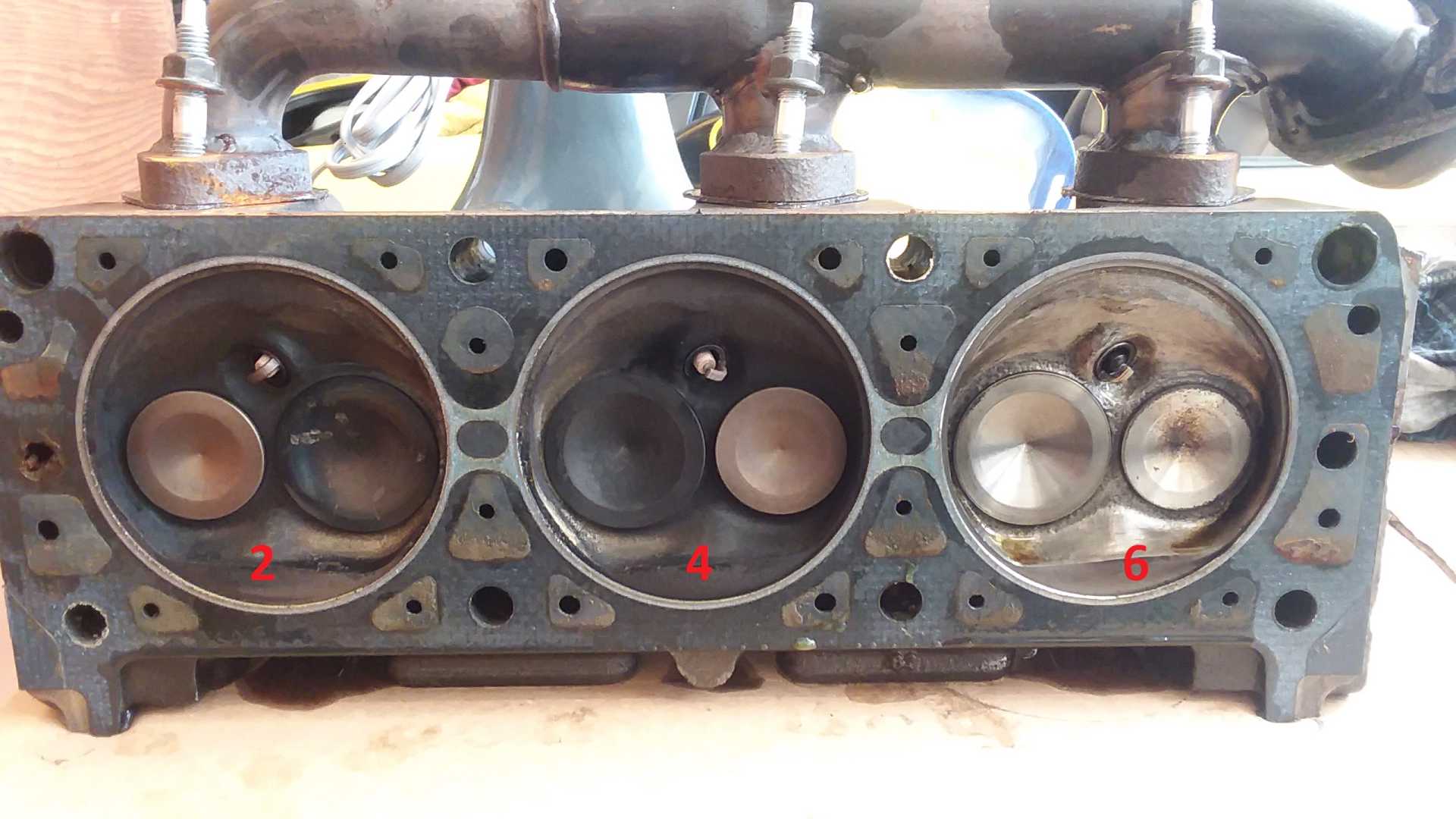

Success ... I'm not hearing things: the misfire is real. The head is off and the diagnostic confirmed ... #6 is as dead as a doornail (no carbon deposits). Also, no sign of valve-strike damage to the piston (and bend the rod) and no obvious cracks to the valve seats (to open a leak path). I was thinking I would drop the head off with the expert Monday AM rather than take it apart myself. Pretty much the only thing I could do would be to re-lap the valves and install new seals. What could be causing the 35% leak-down failure? The head gasket looks fine.

p.s. cylinder #s edited in per request

[This message has been edited by Notorio (edited 08-10-2020).]

|

|

|

Patrick

|

AUG 09, 06:37 PM

|

|

| quote | Originally posted by Notorio:

I brought it to a speed shop... In a one-hour diagnosis to look for a slight misfire he found:

1) Spark OK to all cylinders

2) Compression OK on all cylinders

3) Leak-down test failed on #6 at 35% vs normal of 5% or so.

4) All spark plugs appeared normal except #6 which was fouled with oil

5) Vacuum gauge fluctuations point to incomplete combustion.

|

|

| quote | Originally posted by Notorio:

What could be causing the 35% leak-down failure? The head gasket looks fine.

|

|

I'm curious if the shop did the leak-down test first without, and then with oil being squirted into #6 cylinder?

Wet Compression Test[This message has been edited by Patrick (edited 08-09-2020).]

|

|

|

Gall757

|

AUG 09, 08:48 PM

|

|

How can compression be OK.....and fail a leak-down test....which is checking compression?

Notorio, could you number the combustion chambers on the pic? Why does one chamber look like it has never fired once? (is that #6?)[This message has been edited by Gall757 (edited 08-09-2020).]

|

|

|

pmbrunelle

|

AUG 09, 09:10 PM

|

|

Turn the head upside-down and fill the combustion chambers with kerosene. Leave it overnight.

If you have leaking valves on the "bad" combustion chamber, you'll see the kerosene leak out into the ports (comparing the bad vs good cylinders). A lack of compression can also be due to a problem with the bottom end.

You said that your injectors were tested, but that doesn't mean they were all functional as installed in your Fiero.

If you plug the injectors into the car's wiring, and have a friend crank the car over, do you feel all the injectors clicking?[This message has been edited by pmbrunelle (edited 08-09-2020).]

|

|

|

Notorio

|

AUG 10, 12:36 AM

|

|

| quote | Originally posted by Patrick:

I'm curious if the shop did the leak-down test first without, and then with oil being squirted into #6 cylinder?

Wet Compression Test

|

|

Beats me. I'll ask when I see him tomorrow.

| quote | Originally posted by Gall757:

How can compression be OK.....and fail a leak-down test....which is checking compression?

Notorio, could you number the combustion chambers on the pic? Why does one chamber look like it has never fired once? (is that #6?)

|

|

I have updated the original picture now with the cylinder numbers. My limited understanding was that the Compression Test gives the max pressure while cranking and that the Leak Down Test tracks how well the pressure holds during a two-minute rest, with 5% loss being typical and 35% being indicative of serious trouble. So all the parts taking place in the 'sealing' process are able to hold the pressure briefly for the Compression Test where cranking continues but fail in 'long-term' sealing after cranking has ceased. (Now why that is relevant escapes me. Ogre?? When I think about it I'd presume that if the pressure held 'ok' on the hundred millisecond timescale you'd be good to go, but I'm too tired right now to calculate it out.)

| quote | Originally posted by pmbrunelle:

Turn the head upside-down and fill the combustion chambers with kerosene. Leave it overnight.

If you have leaking valves on the "bad" combustion chamber, you'll see the kerosene leak out into the ports (comparing the bad vs good cylinders). A lack of compression can also be due to a problem with the bottom end.

You said that your injectors were tested, but that doesn't mean they were all functional as installed in your Fiero.

If you plug the injectors into the car's wiring, and have a friend crank the car over, do you feel all the injectors clicking?

|

|

I would LOVE to run that Kerosene experiment except I don't have any.

The injectors were sent to a cleaning and calibrating service that measured the output before and after servicing. I'll have to dig out the paperwork but I recall them being 100% after the cleaning. However, and perhaps this is an ominous point, those were cleaned at the BEGINNING of this 2+ yr adventure so they sat in their little sealed baggies for about 2 years before I put them in and fired the engine up. I'll have to try your experiment tomorrow!

On a side note, I wonder if there are TWO problems here, with Problem 1 causing the leak-down failure but Problem 2 (i.e. #6 faulty injector spraying little-to-no gas into the lower intake runner) causing the 'no-fire' condition that I HEAR as a misfire and FEEL as lack of power, and MEASURE as a vacuum gauge fluctuation, and SEE as a Combustion Chamber that still looks as clean as a baby's behind?? I certainly don't understand how having just Problem 1 would result in Zero Combustion if Gas and Air were actually present.[This message has been edited by Notorio (edited 08-10-2020).]

|

|

|

|