|

| How I Fixed Fuel Sender Binding Problem in 88 Tank (Page 2/4) |

|

Notorio

|

JUN 02, 01:09 PM

|

|

Found one on the Forum posted by Sardonyx247 in 2015, but unfortunately without a reference scale, etc. It's a shame that there are so many old threads where the pictures have disappeared ...

|

|

|

fieroguru

|

JUN 02, 01:18 PM

|

|

Great Job Steve! I have one of these new sending units for my 88, but haven't got around to doing anything with it yet. Thanks for saving me some time!

|

|

|

fierofool

|

JUN 02, 02:09 PM

|

|

|

If anyone wants to swap out floats, I have two used OEM floats. I'm open to offers. Highest bidder plus shipping.

|

|

|

V8Steve

|

JUN 02, 03:51 PM

|

|

Guru, the only downside on this is one of matching materials. The FS rod is stainless steel. I didn't have any stainless rod around and my mig wire is steel. So, unless I sent it out, there was no way I could weld stainless to stainless with a stainless weld.

I think the risk is small for corrosion on the steel float shaft.

|

|

|

fieroguru

|

JUN 02, 04:15 PM

|

|

| quote | Originally posted by V8Steve:

Guru, the only downside on this is one of matching materials. The FS rod is stainless steel. I didn't have any stainless rod around and my mig wire is steel. So, unless I sent it out, there was no way I could weld stainless to stainless with a stainless weld.

I think the risk is small for corrosion on the steel float shaft. |

|

Steve, I weld stainless all the time, so that won't be any issue. Thanks for doing all the hard work figuring out what the issue was and how to easily resolve it.

|

|

|

V8Steve

|

JUN 02, 04:49 PM

|

|

|

It's not the weld that concerns me, but rather the steel shaft that the floats ride on. The unplated steel, hopefully will not interfere with freedom of float movement.

|

|

|

Patrick

|

JUN 02, 05:51 PM

|

|

| quote | Originally posted by V8Steve:

I cut a window in the side of the tank and here’s what I found. The tip of the rod where it exits the float was rubbing on the side baffle.

|

|

Full props to you for sacrificing a tank to see for sure what the heck was going on.

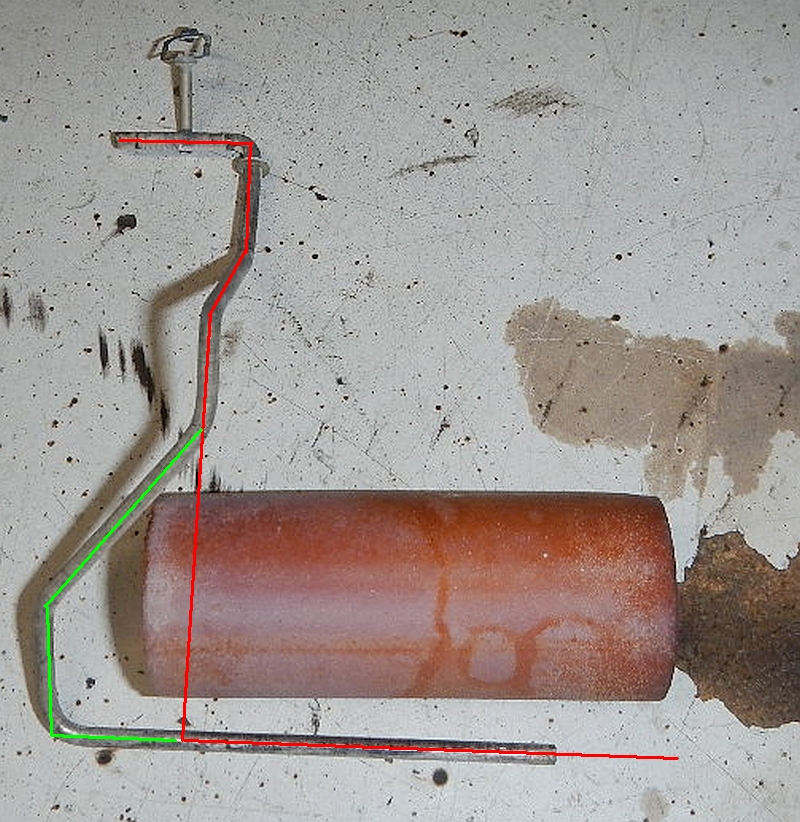

With your photo showing how close the end of the float arm was coming to one side of the tank (and hitting/being hung up on the baffle), it's no wonder the new float arm wouldn't work. In my image below, the red line shows the shape of the new arm superimposed on top of the original arm. The green line shows the missing bends which are critical in order to center the float and avoid rubbing the baffles.

It's unfortunate all this messing about is required to overcome such a "simple" problem.[This message has been edited by Patrick (edited 06-02-2020).]

|

|

|

V8Steve

|

JUN 02, 06:35 PM

|

|

Patrick,

You're absolutely right. Actually, from what I recall, the FS arm was a straight line, in a top view only, from the sensor to the elbow where it enters the float. There was at least one bend from sensor to elbow in another plane. One would have to bend the FS store arm to be like the one in the photo, just like a paint roller. After all that bending, it would be almost impossible to have the float rest on empty due to all the rod length taken up make it like a paint roller. Along the way, there is the risk that the plastic clips on the potentiometer would break off from all the messing around with it.

Once I discovered that, I knew it would be difficult to make a new rod. Another consideration was the length/weight of rod versus buoyancy of the float. That's why I made a T shape and the net weight adder was one push washer and one tiny weld.

After all this effort, I was glad to discover my own tank top leaking with the round seal. I would not want to be driving around with a leaking tank top or even worse, in the event of a rollover, fuel leaking out of the tank top.[This message has been edited by V8Steve (edited 06-02-2020).]

|

|

|

Patrick

|

JUN 02, 06:58 PM

|

|

| quote | Originally posted by V8Steve:

One would have to bend the FS store arm to be like the one in the photo, just like a paint roller.

|

|

A paint roller, exactly! That's a perfect example of the type of bends required to center the float on the "handle" so that it's in the middle of the tank. For the float to go 100% off towards one side on the FS float assembly, that's an inexcusably poor design.

|

|

|

Archie

|

JAN 06, 10:14 PM

|

|

|

A little bump for you Steve.

|

|

|

|