|

| General question about welding up and redrilling a hole on a spindle??? (Page 2/3) |

|

olejoedad

|

MAY 08, 12:09 PM

|

|

And the brake caliper is installed below the centerline of the spindle.

AMS had horrible, terrible fabricating issues. No QC at all from my experience.

"They're painted, and made of metal - good to ship", seemed to be their standard.

I would be very leary of using any of their products on a car that would be used on public highways.

I won't entertain you with my dealings with AMS......

|

|

|

ltlfrari

|

MAY 08, 01:14 PM

|

|

Stock position is about 9 'o'clock. Most conversion seem to put them at 10 o'clock or so so yeah, it looks like your spindles are upside down.

Looks sorta strange too from the side with the rear caliper up high and the front down low.------------------

Anything I might say is probably worth what you paid for it, so treat it accordingly!

Dave

www.ltlfrari.com

|

|

|

fieroguru

|

MAY 08, 02:24 PM

|

|

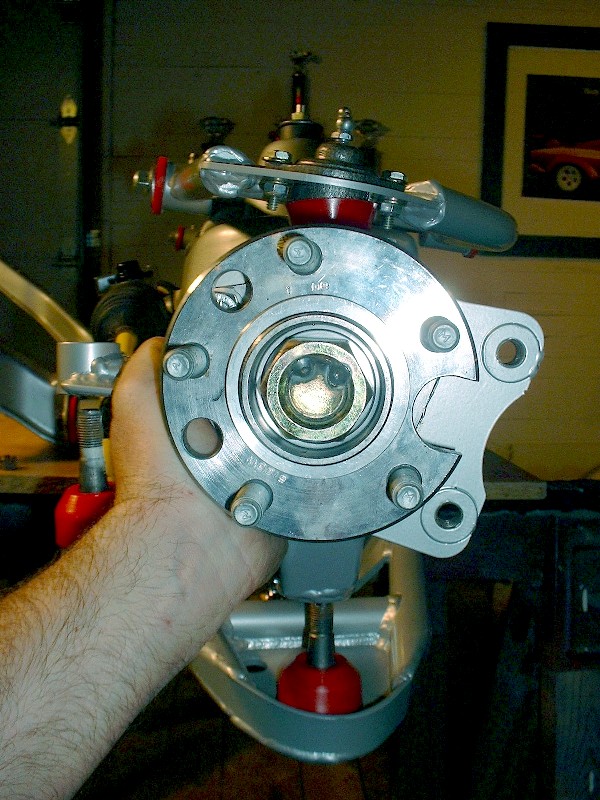

From your pictures, the spindles are installed properly.

Here is a stock 88 spindle - notice the caliper position is nearly parallel with the center-line of the ball joints and vertical. When installed, the upright is rotated back so the caliper ends up below the center-line of the wheel bearing due to running 5 or more degrees of caster.

Here is the stock caliper position with the 5+ degrees of caster. The front brake caliper in the 3:30 position on the driver side (8:30 on the passenger side).

Now there is a poorly designed brake kit for the 88 that uses 12" rotors and rotates the calipers up. This would place them in the 2:30 and 9:30 positions. This brake kit placed the caliper in a position where it would interfere with the upper a-arm. So the perception that the 88 front brakes should have the calipers in the 2:00 or 10:00 position is just plain wrong.

The dropped spindle does the same thing where the caliper and bearing positions all shift up relative to the ball joints and a-arms, so if they left the caliper in the stock 3:30/8:30 position, it too would have likely hit the upper a-arm. So to avoid this interference, they rotated the caliper position further down and away from the upper a-arm.

Here is known good 88 dropped spindle where you can see the caliper position is closed to 4:00. If you imagine the caliper at 3:00 in this picture, you can see the upper a-arm would be right behind it vs. above it and likely have interference issues.

The other major challenge with the concept of installing a spindle upside down is the kingpin angle is built into the spindle. The picture below isn't a scale drawing, but is close to what an 88 spindle looks like. The the centerline between the upper and lower ball joints is the kingpin angle. Flipping this over will cause a major camber issue with the front suspension.

The last issue with installing them upside down is the upper and lower ball joints shafts and holes are different sizes. The lower ball joint won't pass through the hole for the upper ball joint, and the upper won't tighten up in the lower hole.

I suspect what the real issue here is that these are not dropped spindles of the center tube with the scallops was flipped during the assembly process and before any welding. These were marketed as a bearing upgrade as well as various levels of dropped spindles solution. If someone wanted a 1/2" or a 0" drop spindle (more focused on the bearing upgrade than the stances), then they could have made a set. With the lack of quality control that AMS was known for, they could have had a set of 0-1/2" drop spindles on the shelf and when quality issues required replacement, someone could have easily grabbed the wrong set.

As for the size and length of the scallops. If their size was based on the amount of drop, then 1" dropped spindle would have different size scallops top and bottom than a 1 1/2". Also, the scallops are just in a tube that can easily be flipped before the ball joint pucks are installed. When I look at the picture on your car, it looks to me that the material between the two scallops is about 1/2" below the bearing centerline, which would happen if the scallop tube was flipped prior to assembly and welding. It is very clear that AMS assembled these w/o good fixtures ensure proper placement of every part, so it is highly likely the center tube with the scallops could have been flipped during the assembly process.

Measure the distance from the bottom of the spindle at the lower ball joint to the center of the wheel bearing. I can compare this measurement later tonight to my actual drawing.[This message has been edited by fieroguru (edited 05-09-2020).]

|

|

|

fieroguru

|

MAY 09, 05:00 PM

|

|

The distance from the bottom of the spindle at the lower ball joint to the center of the bearing is about 3 5/16".

Measure the ones on the car and that will let know know what spindles are on there.

|

|

|

qwikgta

|

MAY 10, 11:49 AM

|

|

took another photo this morning, I still need to get a tape measure in there.

I don't want to admit your right Paul, but this photo looks like what you were saying about a zero drop and just a bearing change. ????? why.

|

|

|

Will

|

MAY 11, 09:55 AM

|

|

That's what it looks like... it's a (hopefully correctly made!) stock height spindle.

As Paul noted, you would not be able to align the car anywhere close to stock specs with the spindle upside down.

Also, with the tie rod end on the wrong side of the tie rod boss, you'd end up with HEINOUS bump steer that would make the car difficult to drive in a straight line.

|

|

|

Dennis LaGrua

|

MAY 11, 05:37 PM

|

|

|

Wasn't it Arrault Motor Sports that had the problem with their spindles cracking and coming apart? IIRC this is why they stopped making them. If this info verifies then it might not be worth using them and replacing them with good used stock parts. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

olejoedad

|

MAY 12, 07:42 AM

|

|

That has happened with their product.

To be fair, I am not aware of it happening on a street driven car.

The was a video of a Lemons car suffering failure.

|

|

|

wftb

|

MAY 12, 08:54 AM

|

|

I have an original Ryane Motor Sports (became Held then Arraut) catalogue and can confirm that they made a spindle with zero drop. It was used with the Slalom front suspension kit and also if you wanted to install their 12" Wilwood brake kit on an 84-87 car you had to purchase one of these spindles to make it work.

------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms[This message has been edited by wftb (edited 05-12-2020).]

|

|

|

qwikgta

|

MAY 12, 10:28 AM

|

|

In the end i guess it really is on correct, just upset that the 1" drop these things are suppose to have didn't do more for the height issue. I guess i'll have to look at dropping the spring now to get the nose down.

Thanks for all the comments.

Rob

|

|

|

|