|

| Help with engine identification (Page 2/2) |

|

atv_123

|

JUN 18, 07:33 PM

|

|

| quote | Originally posted by Raydar:

Yup. Most definitely a 3.4. Camarobird motor. A very popular swap for the Fiero. Many people say that it's the engine that should have come in the Fiero, from the factory.

Depending upon what has been done, you're probably looking at ~165-200 HP. (Stock 3.4 is ~160. Ported heads and intake, a big cam, and tuned headers will get you closer to 200.)

Have any pics of the car? Someone here will probably recognize it, and maybe even identify the build. There might even be a thread on here that documents the whole thing.

Oh... Welcome to our obsession!

Edit - Based upon the orientation of the shift cables, you have the Isuzu tranny. I had one in my 3.4 car for a while.

It's a nice shifting trans, but you don't want to shock load it. (IOW, no "clutch dumps" or speed shifting.) 2nd gear is usually the "weak spot".

If you want to "beat on it", I might suggest a Getrag swap, or even better, an F23. But if you drive it sanely, the Isuzu will do fine.

|

|

Well that's nice to know... now I finally know what on earth is in this thing.

I have heard about the weakness in the Isuzu tranny, but just how weak is weak? I don't treat transmissions very hard at all and like to keep my shifts as smooth as possible... can't beat nailing a perfect downshift... but this car seems to have a slightly sticky throttle cable (right at the bottom of the travel) which makes taking off smoothly rather difficult. (fast or otherwise)

I ask that question because my previous car was a Saab 900 which had a really delicate second gear... like... REALLY delicate.

I might do a transmission swap in the future anyways depending on what happens (you know how these things go). Do there happen to be any options with a limited slip diff? I ask only because I have noticed that the Isuzu doesn't seem to have one and with some of the roads around here... an LSD would really come in handy. (tripoding to enter a side road around here because of the massive change in elevation is nothing out of the ordinary... so it helps to have a way to put the power to the wheel that isn't in the air)

As for power... I would like to get it up as far as possible... not like... internal rebuilding but you know... the usual exterior type bolt on stuff... or perhaps something even more.

As for pictures of the car, you guys might recognize it... he did come here a lot for help judging by all the different tutorials he printed out.

|

|

|

pmbrunelle

|

JUN 18, 08:45 PM

|

|

| quote | Originally posted by atv_123:

I have heard about the weakness in the Isuzu tranny, but just how weak is weak? I don't treat transmissions very hard at all and like to keep my shifts as smooth as possible... can't beat nailing a perfect downshift...

|

|

It's not that bad; I had an Isuzu behind a V6 Fiero for a number of years and it didn't break. However, YMMV.

| quote | Originally posted by atv_123:

but this car seems to have a slightly sticky throttle cable (right at the bottom of the travel) which makes taking off smoothly rather difficult. (fast or otherwise)

|

|

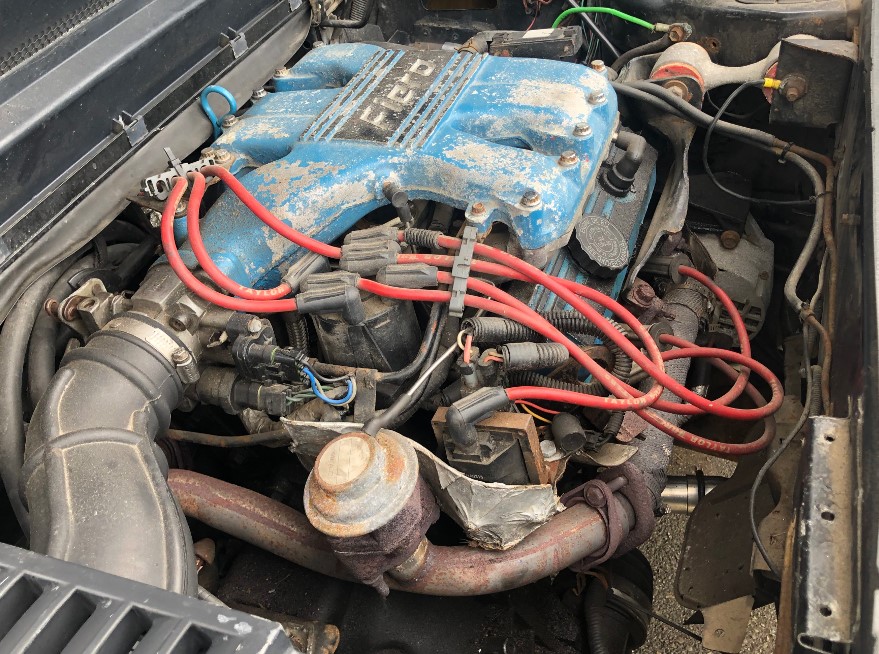

In one of the pictures, we can see that the shift cables are very close to the throttle linkage; looks like the throttle linkage may hang up on the shift cables.

The Isuzu's shift cables are not ideal with the V6 Fiero intake system; on my Fiero I routed the cables over the rubber intake tube, rather than under. This didn't force an unnatural bend right out of the transmission-mounted bracket. The rubber tube fits underneath the cables, with persuasion.

Then, to keep the cables away from the throttle body, I made a hook from coat-hanger wire to keep the cables away from the throttle body. The hook was anchored to the LH decklid hinge box. You should only pull the minimum to avoid hanging up the throttle linkage on the cables; the less that cables are bent, the less friction they'll have.

Remember than the engine moves on its mounts, so whatever clearance you have at rest isn't the same during launch.

| quote | Originally posted by atv_123:

Do there happen to be any options with a limited slip diff? I ask only because I have noticed that the Isuzu doesn't seem to have one and with some of the roads around here... an LSD would really come in handy. (tripoding to enter a side road around here because of the massive change in elevation is nothing out of the ordinary... so it helps to have a way to put the power to the wheel that isn't in the air)

|

|

LSD's are not (to my knowledge) found stock in GM econobox transmissions. It is in general an aftermarket item that you purchase and install in your transmission.

Welding the diff is an option.

If you have a rear sway bar installed, you may try removing it. This may allow the inside wheel to droop further and more easily maintain contact with the road.

|

|

|

Raydar

|

JUN 19, 07:25 PM

|

|

|

That's a beautiful 85. I don't recognize it from the Forum, however.

|

|

|

atv_123

|

JUN 20, 11:23 AM

|

|

| quote | Originally posted by Patrick:

You definitely want to either replace the factory heat shields that are missing on the exhaust crossover pipe... or heat wrap that pipe. Your ICM will thank you.  |

|

That's a really good point. I don't even know what thing the PO tried to install to do that. To me it just looks like a bent piece of sheet metal with some heat tape on it. It probably doesn't do a very good job so I will look to see if I can find the stock replacement as melting things isn't really at the top of my agenda.

| quote | Originally posted by pmbrunelle:

In one of the pictures, we can see that the shift cables are very close to the throttle linkage; looks like the throttle linkage may hang up on the shift cables.

The Isuzu's shift cables are not ideal with the V6 Fiero intake system; on my Fiero I routed the cables over the rubber intake tube, rather than under. This didn't force an unnatural bend right out of the transmission-mounted bracket. The rubber tube fits underneath the cables, with persuasion.

Then, to keep the cables away from the throttle body, I made a hook from coat-hanger wire to keep the cables away from the throttle body. The hook was anchored to the LH decklid hinge box. You should only pull the minimum to avoid hanging up the throttle linkage on the cables; the less that cables are bent, the less friction they'll have.

Remember than the engine moves on its mounts, so whatever clearance you have at rest isn't the same during launch. |

|

I will try my best to take all of that into account. I thought the shifter seemed a little stiff as well (gotta love smooth shifts) and was looking for ways to make it smoother. I will try rerouting the cables as smoothly as possible and try the tricks you suggest to get the gear action a bit smoother.

As for the throttle... it is really close, I suppose it could be getting caught on something. I originally thought the throttle body was sticking so I took off the rubber intake hose and tried cleaning it all out. It was a little dirty... but not sticky throttle body dirty. And I guess I worded my post wrong originally now that I look at it. When I said my throttle sticks at the bottom of the travel, that makes it sound like its sticky near full throttle. To clarify, my throttle is sticky for the first 1/3rd of the pedal travel... once you get past that, the travel is nice and smooth. This makes driving the car fast nice and easy, but inversely, driving like a normal citizen is rather difficult because fine throttle control in the beginning of the pedal travel just doesn't exist. This leads to rather bumpy starts or rather aggressive throttle input changes at low speeds when all I wanted to do was press the throttle ever so slightly harder to increase my speed slightly... not jump for 15 to 40mph.

Long story short... any help on rerouting cables to get smoother operation is a plus in my book and I will try anything.

Also, side tangent, is there an easier way to mount the rubber intake tube? That thing was a major pain to re install... heck... I am not even 100% sure I got it all the way back on there. It really fought me tooth and nail when I was trying to put it back on there.

| quote | Originally posted by pmbrunelle:

LSD's are not (to my knowledge) found stock in GM econobox transmissions. It is in general an aftermarket item that you purchase and install in your transmission.

Welding the diff is an option.

If you have a rear sway bar installed, you may try removing it. This may allow the inside wheel to droop further and more easily maintain contact with the road. |

|

I have done a lot of reading over the past day or so... you are correct. As far as I can see, no normal Fiero transmission swap would yield a OEM LSD.

I have found a few options for ones that can be installed in the stock transmissions, could be worth the trouble for me... will have to do some more research into exactly what all is involved in swapping the diff in one of these transmissions. A decent number of roads in my area are gravel/dirt and have extreme elevation changes (as I alluded to before) thus the reason that I brought the LSD thing up. Is it necessary? No, not at all... just makes things easier when you have to deal with dirt/mud/uneven ground and whatever else gets thrown my way.

I could weld it I guess... but man... that just sounds like it could be pretty harsh to live with.

losing the rear sway bar would help keep the tires on the ground... your right about that in every way. But I gotta say... when I actually do find a proper road (or even just a halfway smooth dirt/gravel road) I absolutely LOVE the way this thing handles. The car loves to rotate into corners, and that's just the way I like it. Taking out the rear sway bar would also increase traction in the rear and increase the amount of understeer that the car would display... and honestly... I like sliding around too much to let that happen XD

So hilariously... I want to leave in the sway bar because it reduces rear end traction... something I was trying to fix by adding an LSD. It's backwards logic I guess when you look at it that way... but you know... pretend we are making a rally car here I guess as that's the kind of terrain I deal with on a daily basis. Good handling and a way to maximize power to the ground.

I can also switch up the tires to deal with the traction problems... will have to look into my options as my requirements are kind of unusual to most Fiero owners I would guess.

| quote | Originally posted by Raydar:

That's a beautiful 85. I don't recognize it from the Forum, however. |

|

It is a very nice car... came with its own teething problems most of which I have fixed now... but considering all the times he apparently came to these forums, I would be surprised if he never posted. But... it is possible. There is a TON of information on here, so perhaps he just never had to ask a question.[This message has been edited by atv_123 (edited 06-20-2019).]

|

|

|

pmbrunelle

|

JUN 20, 12:43 PM

|

|

Have you thought of an adjustable sway bar?

With this style of sway bar:

https://www.teambgb.com/Tar...arett_987rbldsba.htm

It is possible to adjust the stiffness from the cabin. Using a cable, you can rotate the lever arm from the "easy" direction to the "hard-to-bend" direction.

Forum member La Fiera likes welded diffs; you may ask him for opinions/comments in his thread:

http://www.fiero.nl/forum/Forum2/HTML/140750.html

Here is how I routed the cables on my Isuzu Fiero:

http://www.fiero.nl/forum/A...11-1-081032.html#p13

Only one cable was hanging up on the throttle body; that's the one I pulled out of the way.

To facilitate the rubber intake tube installation, I suggest unclamping the shift cables from their mount. Now, you can install the rubber tube without having to force against the shift cables.

Then, clamp down the shift cables into their mount. As you clamp down the cables into their receptacles, they will push into the rubber intake tube and create the space they need.

|

|

|

atv_123

|

JUN 20, 02:17 PM

|

|

| quote | Originally posted by pmbrunelle:

Have you thought of an adjustable sway bar?

With this style of sway bar:

https://www.teambgb.com/Tar...arett_987rbldsba.htm

It is possible to adjust the stiffness from the cabin. Using a cable, you can rotate the lever arm from the "easy" direction to the "hard-to-bend" direction. |

|

It's not so much that I didn't think about it as much as I didn't even realize that this was a thing. That is really cool... little pricey, but really cool nonetheless.

| quote | Originally posted by pmbrunelle:

Forum member La Fiera likes welded diffs; you may ask him for opinions/comments in his thread:

http://www.fiero.nl/forum/Forum2/HTML/140750.html

Here is how I routed the cables on my Isuzu Fiero:

http://www.fiero.nl/forum/A...11-1-081032.html#p13

Only one cable was hanging up on the throttle body; that's the one I pulled out of the way.

To facilitate the rubber intake tube installation, I suggest unclamping the shift cables from their mount. Now, you can install the rubber tube without having to force against the shift cables.

Then, clamp down the shift cables into their mount. As you clamp down the cables into their receptacles, they will push into the rubber intake tube and create the space they need. |

|

Alright, I will give that a try once I get the brakes all installed and what not (throwing new brakes on the car... the old ones were shot... UPS supposedly delivered them today). I'll also try to check all the cable routing and see if there are any kinks I can remove as you never know.

Also, that's a super clean engine bay. I am impressed with how good it looks![This message has been edited by atv_123 (edited 06-25-2019).]

|

|

|

pmbrunelle

|

JUN 20, 10:51 PM

|

|

I've actually seen a modified car in my town with that type of adjustable sway bar.

The web page I linked to was just the first one I found with a decent picture to explain the concept, while I was rushing to finish posting before the end of the lunch break.

I'm guessing that it's possible to implement such a setup for less money than that.

Here is another photo I found showing how a cable is attached to rotate the lever arm:

|

|

|

|