|

| The White Bug (Page 17/46) |

|

pmbrunelle

|

JUN 16, 10:41 PM

|

|

| quote | Originally posted by Will:

the BARO reading taken from the MAP sensor before the engine turns compensates barometric pressure. |

|

I'll occasionally turn the key to run while the car is in motion, in gear, the wheels driving the engine.

Historically, I don't think there's ever been a restriction on switching on the ignition to a car, besides having an appropriate amount of timing advance. If the OEMs added a startup requirement while retaining the same user interface (steering wheel, pedals, shifter), that's bad user interface design.

My expectation as a user is that if a device looks the same from the outside, I should be able to use it in the same way as usual!

Anyway, if a fuel-injected car drives wonky after I drive it, I'll now have a possible explanation for things... I am kind of shocked at a product initialization that depends on non-obvious user actions.

My truck doesn't mind being turned on/off while rolling, but it has a MAF.

|

|

|

Will

|

JUN 17, 09:09 AM

|

|

|

It's also pretty easy for OEM's to filter that situation out and use a default BARO value.

|

|

|

La fiera

|

JUN 17, 10:58 AM

|

|

| quote | Originally posted by pmbrunelle:

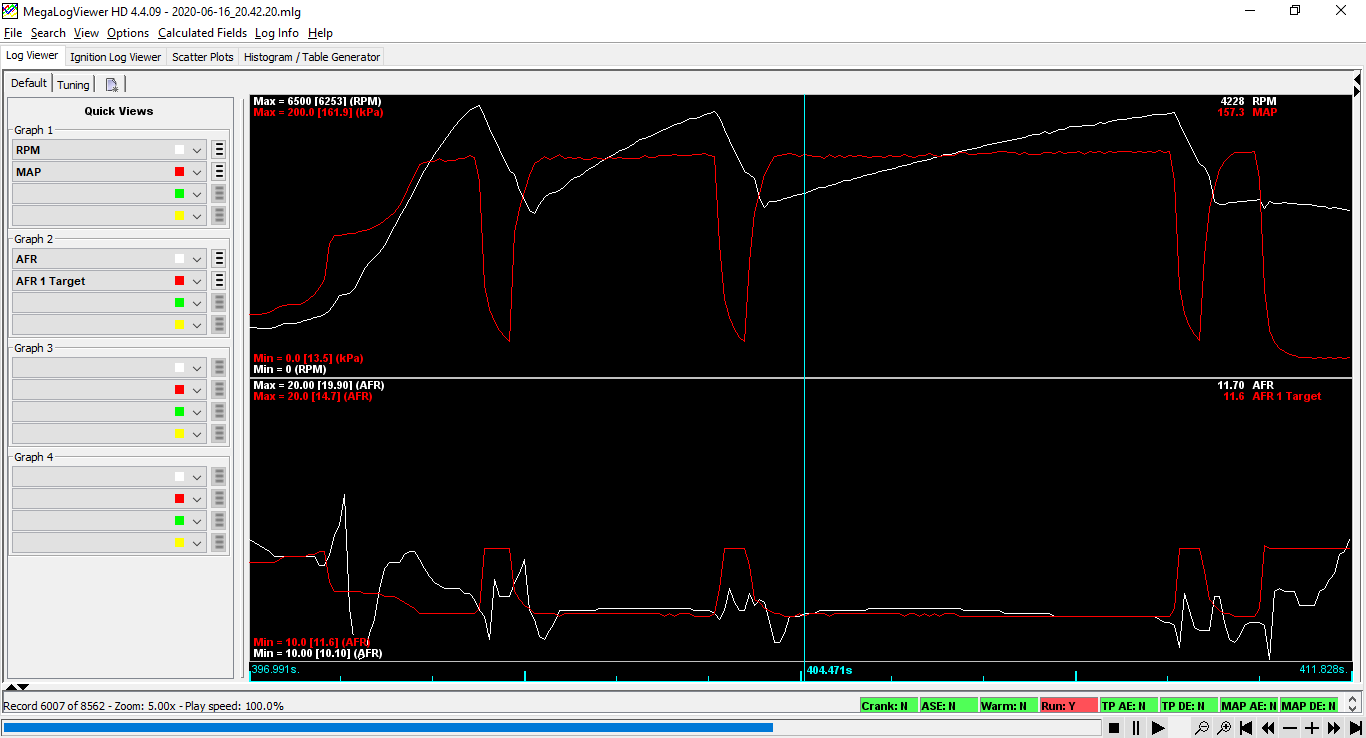

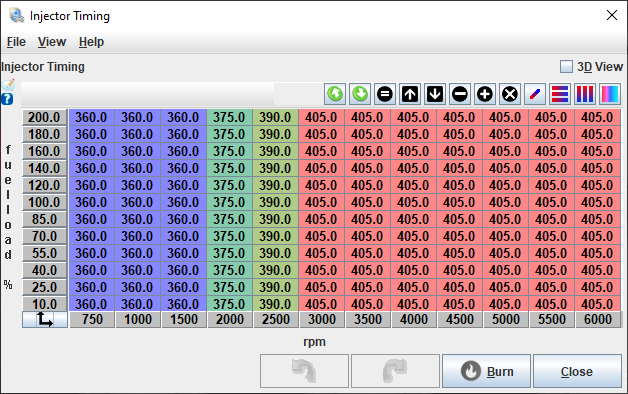

I worked on the injection timing in the last few days.

In the previous datalog I posted, you'll notice short-duration lean AFR spikes when I got back on the throttle after a shift.

No matter what I did with the acceleration enrichment settings, I could not tune out the lean spikes. I surmised that with the uniform 360° BTDC compression injection timing, the squirt (with the acceleration enrichment shot) wasn't making it into the cylinder on time, leaving the first cycle after a shift lean.

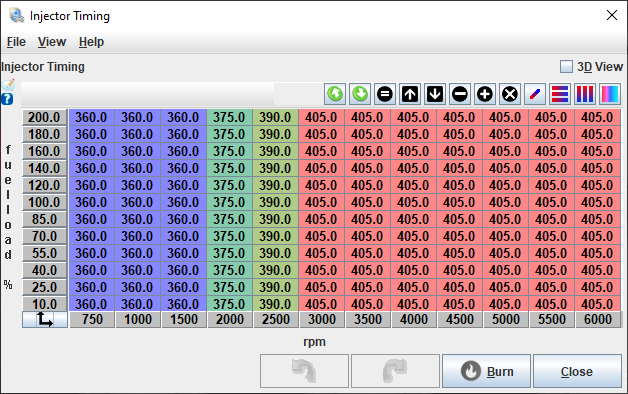

I played with the injection timing in 45° increments. Advancing the 3000+ RPM injection timing to 405° worked best:

Advance beyond 405° was not beneficial. The more the fuel is advanced relative to the intake event, the more time there is for an airflow change to occur between the squirt (and thus fuel mass calculation) and the intake event. Transient response was less good with more advance.

At low speeds / idle, I retained the default 360° timing:

Initially, I thought that I should finish the squirt just before the intake valve closing. This would minimize the time during which a sudden airflow change could cause the injected fuel mass to be incorrect for the air mass that's about to be sucked into the cylinder.

Squirting on a wide-open intake valve gave lean spikes. I think that the fuel was entering the combustion chamber (on time) as large droplets, not burning completely, and then exhausted as unburned HC.

I think that my philosophy for injection timing is to do it as late as possible, while still finishing the squirt on a closed (or barely opened) intake valve. This would apply to the White Bug; other engines may react differently? |

|

You know all that is going to change once you install the bigger injectors, you'll have to re tune again.

PS They are on your way.

|

|

|

Will

|

JUN 17, 01:33 PM

|

|

| quote | Originally posted by pmbrunelle:

Advance beyond 405° was not beneficial. The more the fuel is advanced relative to the intake event, the more time there is for an airflow change to occur between the squirt (and thus fuel mass calculation) and the intake event. Transient response was less good with more advance.

At low speeds / idle, I retained the default 360° timing:

Initially, I thought that I should finish the squirt just before the intake valve closing. This would minimize the time during which a sudden airflow change could cause the injected fuel mass to be incorrect for the air mass that's about to be sucked into the cylinder.

Squirting on a wide-open intake valve gave lean spikes. I think that the fuel was entering the combustion chamber (on time) as large droplets, not burning completely, and then exhausted as unburned HC.

I think that my philosophy for injection timing is to do it as late as possible, while still finishing the squirt on a closed (or barely opened) intake valve. This would apply to the White Bug; other engines may react differently? |

|

The 405 number is where to stop the injector on time before TDC compression/power? And you're saying that you want to complete the injection before the intake valve opens?

|

|

|

pmbrunelle

|

JUN 17, 07:01 PM

|

|

| quote | Originally posted by La fiera:

You know all that is going to change once you install the bigger injectors, you'll have to re tune again.

PS They are on your way. |

|

I think that a tuner becomes a good tuner by tuning many different kinds of engines/setups.

Since I am an inexperienced tuner, getting my current setup working is giving me useful experience. So even if I have to retune later with a different setup, I do not feel that my present activities are a waste of time.

I can't complain about getting parts sent to me!

| quote | Originally posted by Will:

The 405 number is where to stop the injector on time before TDC compression/power? |

|

Yes, that's right. Given the desired injector on-time, engine speed, and engine acceleration, the ECU schedules the injector turn-on such that the turn-off occurs at the angle specified in the look-up-table.

The injector turn-off angle is not exact; priority is given to the correct injector on-time, to the detriment of end-of-injection timing accuracy.

Ignition dwell works a bit differently; priority is given to firing the ignition coil at the correct angle, to the detriment of dwell time accuracy.

| quote | Originally posted by Will:

And you're saying that you want to complete the injection before the intake valve opens? |

|

Yes, that's what's working "best" on my Fiero, for now.

I define "best" in terms of minimizing the lean spikes when I stomp on the throttle following gearchanges on a 1-2-3-4 WOT run from idle. I kept the same acceleration enrichment settings as I varied the injection timing. I was working in increments of 45°.

I am not studying the influence of injection timing on steady-state power.

|

|

|

pmbrunelle

|

JUL 04, 12:01 AM

|

|

Thursday night I noticed a ticking sound occur. It was mostly prominent at idle, going away with RPMs. Maybe it existed before, but not at a level to notice.

The local tuning shop heard the car, and the owner said that the tick was the sound of a bad lifter.

After taking off the valve covers, I found a VERY worn rocker pivot ball:

I also found coked oil on the rocker itself:

Maybe it's time to switch to synthetic oil.

To be continued...[This message has been edited by pmbrunelle (edited 07-04-2020).]

|

|

|

ericjon262

|

JUL 04, 01:58 AM

|

|

|

Gross! were all of them like that or just the one? ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

https://joj2020.com/ <--- She isn't a sexual predator.

|

|

|

La fiera

|

JUL 04, 09:05 PM

|

|

|

Maybe the pusrod was plugged up with debris?! What kind of oil did you use?

|

|

|

pmbrunelle

|

JUL 04, 10:19 PM

|

|

| quote | Originally posted by ericjon262:

Gross! were all of them like that or just the one?

|

|

All of the rockers had some degree of coked oil, but this one was the worst. The coking seems to be concentrated near the heat generated by friction of the ball pivot point.

As for the other balls, I'm not sure, I haven't taken apart the others yet. I was busy today working on my friend's 3.5 Fiero swap. This rocker is the only one that was loose though; when I took off the valve covers, I was able to wiggle this one by hand. The others felt normal.

The 3.5 already has roller trunnion rockers from the factory, so this is a problem you won't have to deal with.

| quote | Originally posted by La fiera:

Maybe the pusrod was plugged up with debris?! What kind of oil did you use? |

|

I took out the pushrod, and I was able to see through it.

Startup oil (0 km): Shell Rotella T4 15W-40 + extra 915 ppm phosphorus, 1104 ppm zinc

2nd oil change (100 km): Shell Rotella T4 15W-40 + extra 915 ppm phosphorus, 1104 ppm zinc

3rd oil change (1603 km): Shell Rotella T4 15W-40 + extra 458 ppm phosphorus, 552 ppm zinc

I noticed the tick at about 1800 km.

I limped home and the engine now has 2042 km.

I cut down on the ZDDP additive (Redline Break-In Additive) because I read that too much ZDDP isn't good long-term. Maybe that was a mistake. I don't know how much phosphorus/zinc is already in the oil as-purchased.

Before taking things apart further to study the balls, I will put back the failed rocker+ball, re-adjust the lifters, and then spin the oil pump (with a drill + modified distributor) to see if oil comes out of all 12 pushrods.

|

|

|

La fiera

|

JUL 05, 06:06 PM

|

|

ZDDP is a very good extreme pressure protector but is very inneffient. How so you may ask? The more pressure is exerted on ZDDP the more drag it develops between the sliding surfaces and that drag can induce overheating of parts, and that's not counting the energy wasted trying to overcome that friction. I've seen many new engines ruined because of overdose of ZDDP

But not all is lost. There are two elements that do just the oposite, the more pressure exerted in between the sliding surfaces, the slickery and slipery those elements get thus reducing friction to a very minimum amout. Enter Molibdenum disulfide and Tungsten disulfide.

The first one is availabe in powder form or part of the chemestry of the oil, in other words the oil has additives to keep the Molibdemum suspended in the oil.

The problem with using it in powder form is that Molibdenum is a heavy solid element and if pouedr in oil it will just sit at the bottom.

I personally use M0S2 solid powder to mix it with assembly lube and bearing lube. I also have a propietary blend of Tungsten disulfide that stays suspended in the oil and does not sink like if used in powder form and that I add to all the oils that go on my engines.

So, if you want to have a long lasting engine regardless is a street or performance engine, specially if you use the old flat tapped cam design the best oil you can buy is:

I personally use this oil for break-in of my engines, that's how good it is!

Good luck patrick

|

|

|

|