|

| 4.6 Northstar Swap Project (Page 15/22) |

|

copperhens

|

JUL 24, 01:36 PM

|

|

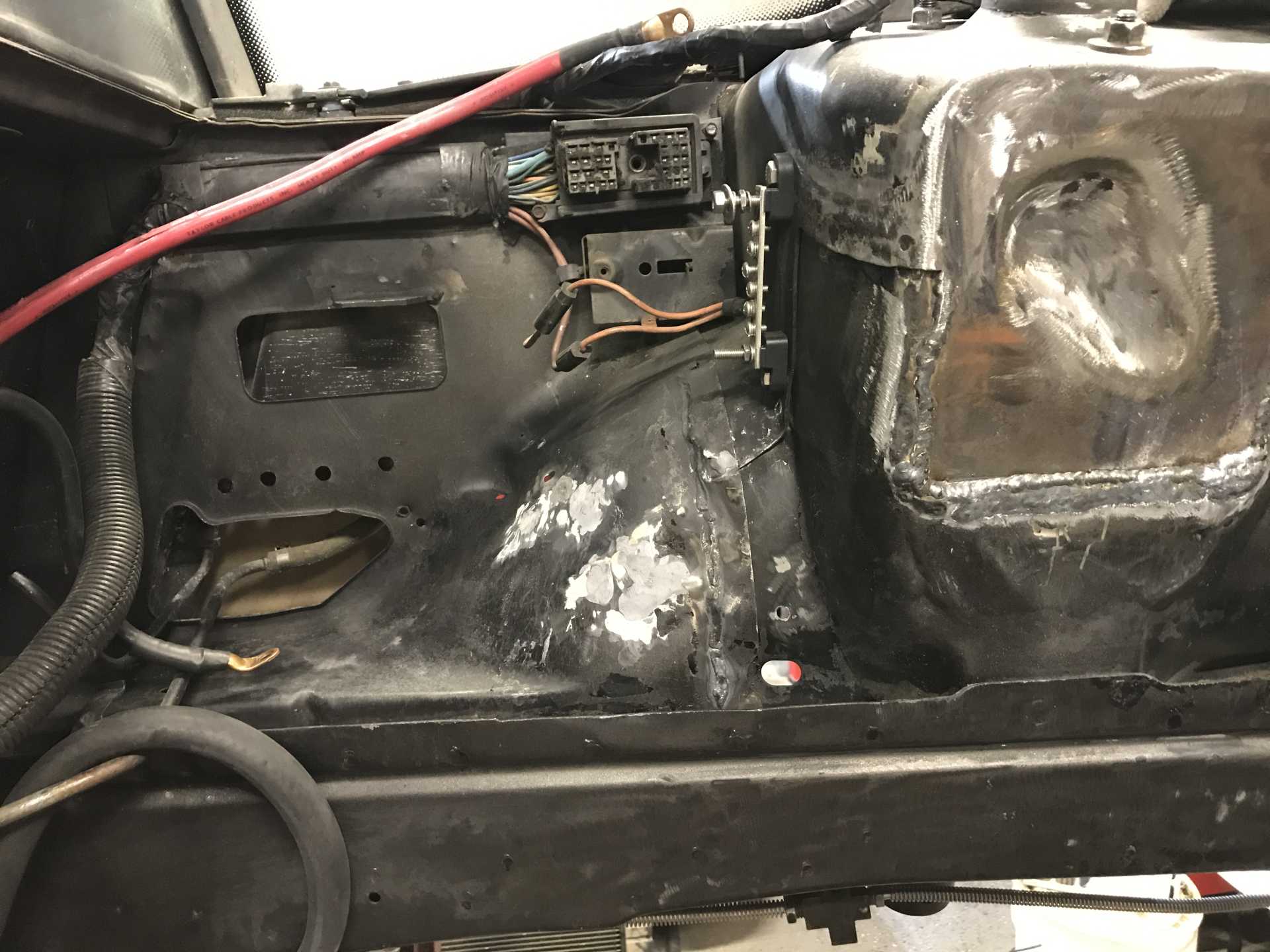

3/27/21

More prep, this time on the firewall. More prep revealed more bondo. For what it’s worth, PO laid it well and it was smooth.

Another picture of the work on the passenger side.

|

|

|

copperhens

|

JUL 24, 01:42 PM

|

|

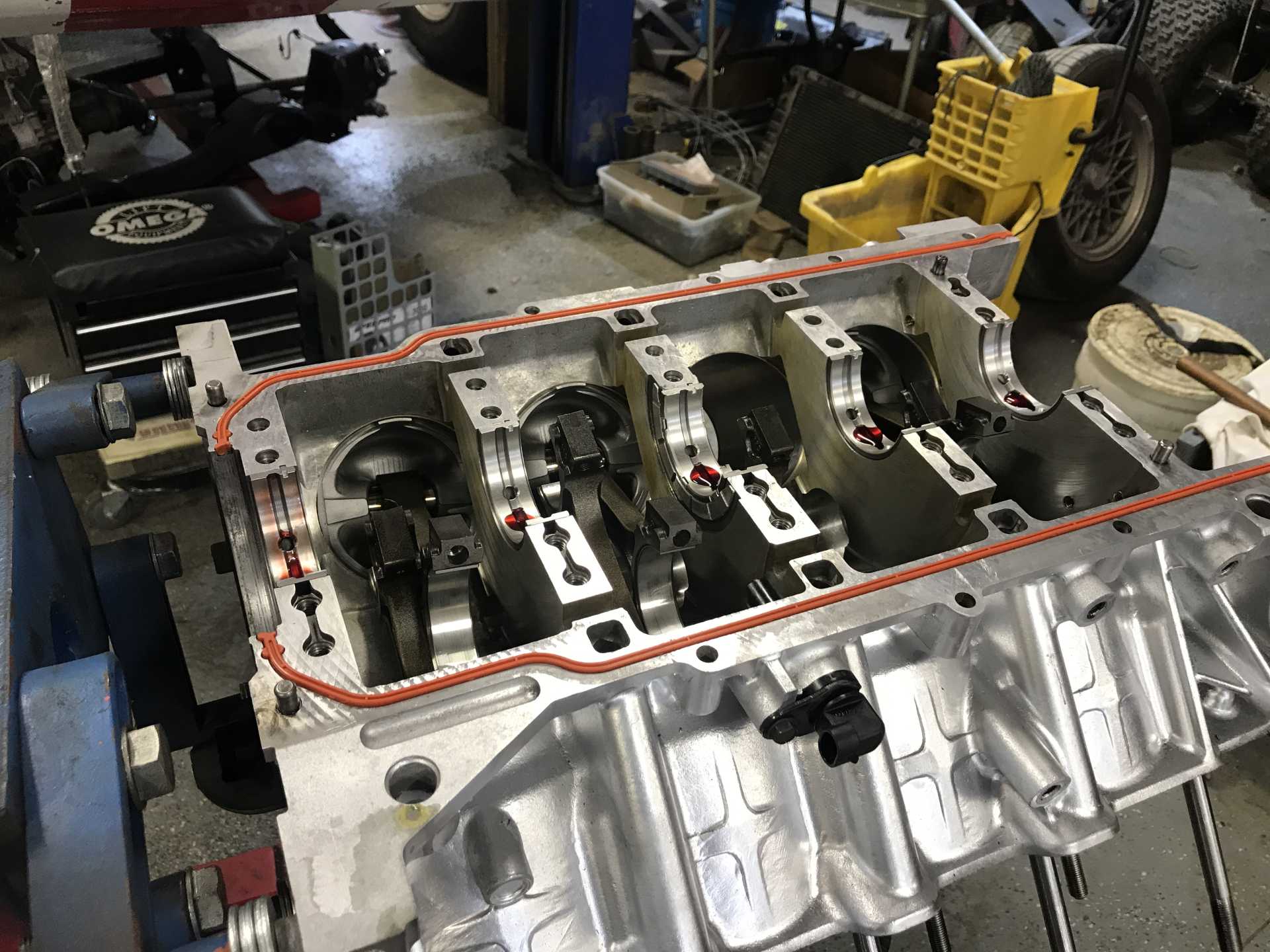

4/11/21

Back to the motor. My new bearings came and Mr. Eric and I installed all new main bearings. Even though the thrust bearing was the only bad one, might as well.

Got the bottom end together more.

And now all the way together! It helped a lot of this stuff was clean from the first time around. Of course I had to flush everything again to get metal flakes out.

|

|

|

copperhens

|

JUL 24, 01:45 PM

|

|

4/16/21

I’ve been just dabbling on the engine bay while waiting for things for the motor.

|

|

|

copperhens

|

JUL 24, 01:47 PM

|

|

4/18/21

A day for a break. My boyfriend, Paul, and I went to the MI Fiero Club general meeting to take a break from all the work we’ve been doing on the Northstar.

My GT and his Formula.

|

|

|

copperhens

|

JUL 24, 01:48 PM

|

|

4/23/21

Got my valve covers powdercoated. Before I painted them with expensive Eastwood high temp paint, but with everything that went on with the engine, they got chipped on some spots.

|

|

|

copperhens

|

JUL 24, 01:51 PM

|

|

5/16/21

Head rebuild day! As a recap, lack of oil pressure ruined some of the cam caps. You can’t just buy new ones because they are machined for each cap. So, Mr. Eric made a program to remachine the caps. All the program did was cut mere thousandths of an inch off the cap, and to compensate, cut the same amount off the mounting points so it would sit flush again.

Here is a picture of the damage on the head that sanded out. I thought I had a picture of the caps. There were 3 that needed to be remachined. The cams on the rear head were polished as well as all the cam surfaces. Clearances were measured and were good.

I did not take apart the front head. There was no damage to any of the caps. I did clean it out really good though. Both heads were cleaned in the parts washer and blown out to dry.

|

|

|

copperhens

|

JUL 24, 01:58 PM

|

|

5/23/21

I half heartedly painted the transmission to make it appear better. While the getrag should hold up, I have plans to upgrade to an f23 or f40. I also hit the axles too, and I’ll apologize now for painting the boot too.

Mr. Eric and I got the heads back on. I remember we put the one on backwards, don’t ask me how, but it was very difficult to get back off lol.

Alright now I’m drooling a bit.

I again sound like to thank Mr. Eric for the lift. The car was up there way too long.

|

|

|

copperhens

|

JUL 24, 02:08 PM

|

|

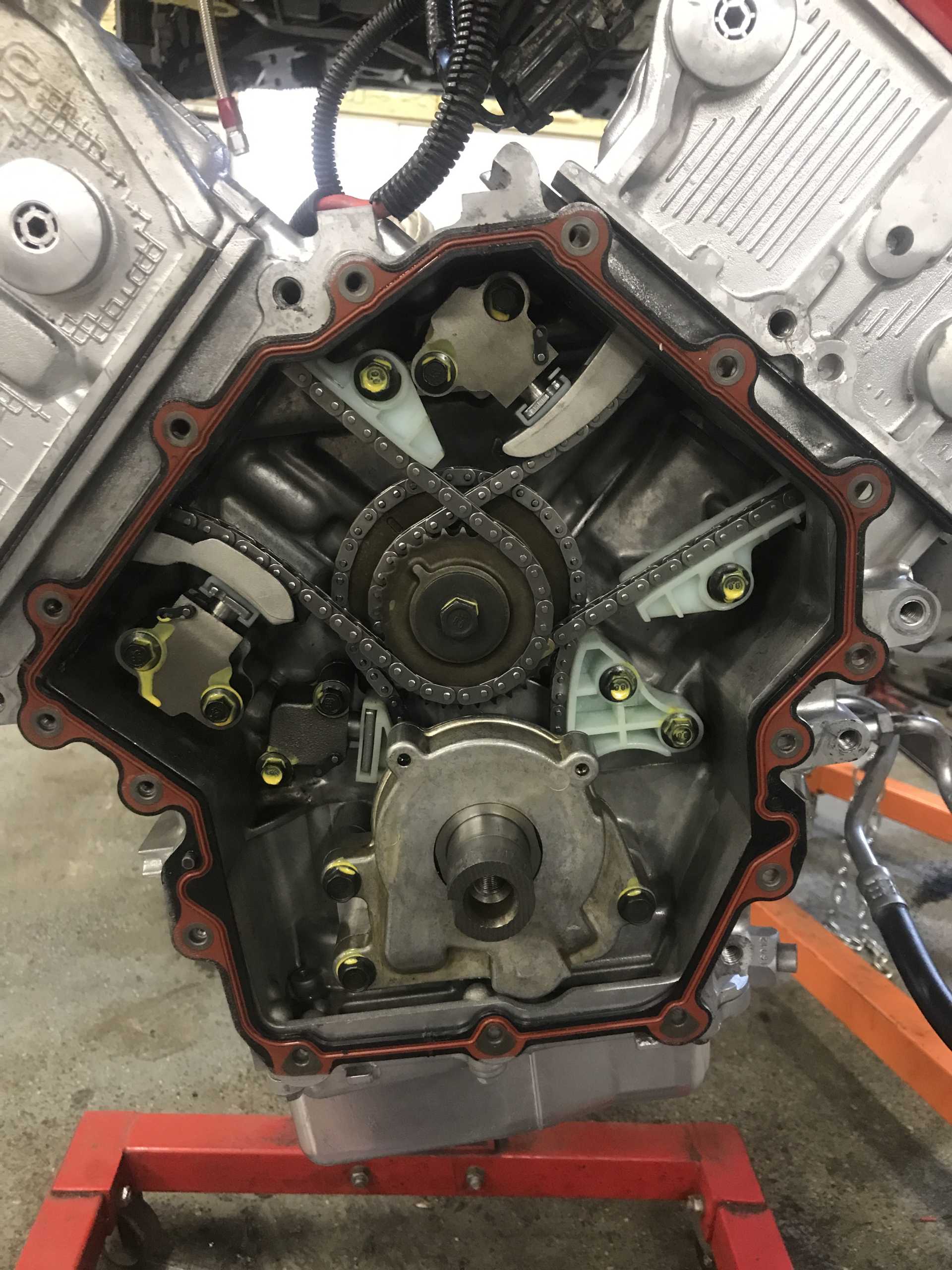

5/24/21

Mr. Eric and I worked on the timing. There was a bit of trouble on the caps that were remachined. We pulled them and had to sand them even more because the slightest imperfection caused the cam to drag. You can see the faint darker spots that we polished smooth.

I’ll include this for educational purposes. Where the timing chains wrap around the gear, there is a threaded hole. I did not have a bolt in my bag that would go here. I instead found the bolt with the massive washer that threaded in there in my engine mount bag…

Where I’m going with that is, when I took the engine apart originally, my organizational skills were subpar. I believe I never put this bolt in, and instead recycled it as an engine mount bolt. When we took it apart a second time, I don’t recall if this hole was plugged or not. If it wasn’t, it would hemorrhage oil due to the galleries that run up through it. My oil pressure problem either occurred due to a loose harmonic balancer, or the lack of this bolt. The first time around was user error though, and I gotta say I learned from it. This time around, the Northstar and the car are better than ever. Live and learn.

Here is the bolt hole I am talking about.

The timing is now all together, and torqued to spec. You can tell be the excessive paint marking.

I hope the engine is happy this time.

|

|

|

copperhens

|

JUL 24, 02:11 PM

|

|

5/27/21

I have a picture here of my dipstick. You can’t tell from this angle, but the tube is bent. The bend caused my dipstick to crack at the bottom and not read oil level unless at max. While I wouldn’t fix this until June, it ended up being a big production because Northstar dipsticks and tubes are impossible to find apparently.

I also took my alternator all the way apart and painted it. It was brand new, but the exposed aluminum would corrode over time.

|

|

|

copperhens

|

JUL 24, 02:13 PM

|

|

5/28/21

I worked on installing the belt drive system. I took apart every pulley, sand blasted it and painted them again. I even stripped and painted the bolts again too.

|

|

|

|