|

| The White Bug (Page 15/46) |

|

pmbrunelle

|

JUN 10, 07:28 PM

|

|

Six weeks after the first start, a number of issues have been resolved, but there is still a lot of work to do before the car is up to my satisfaction!

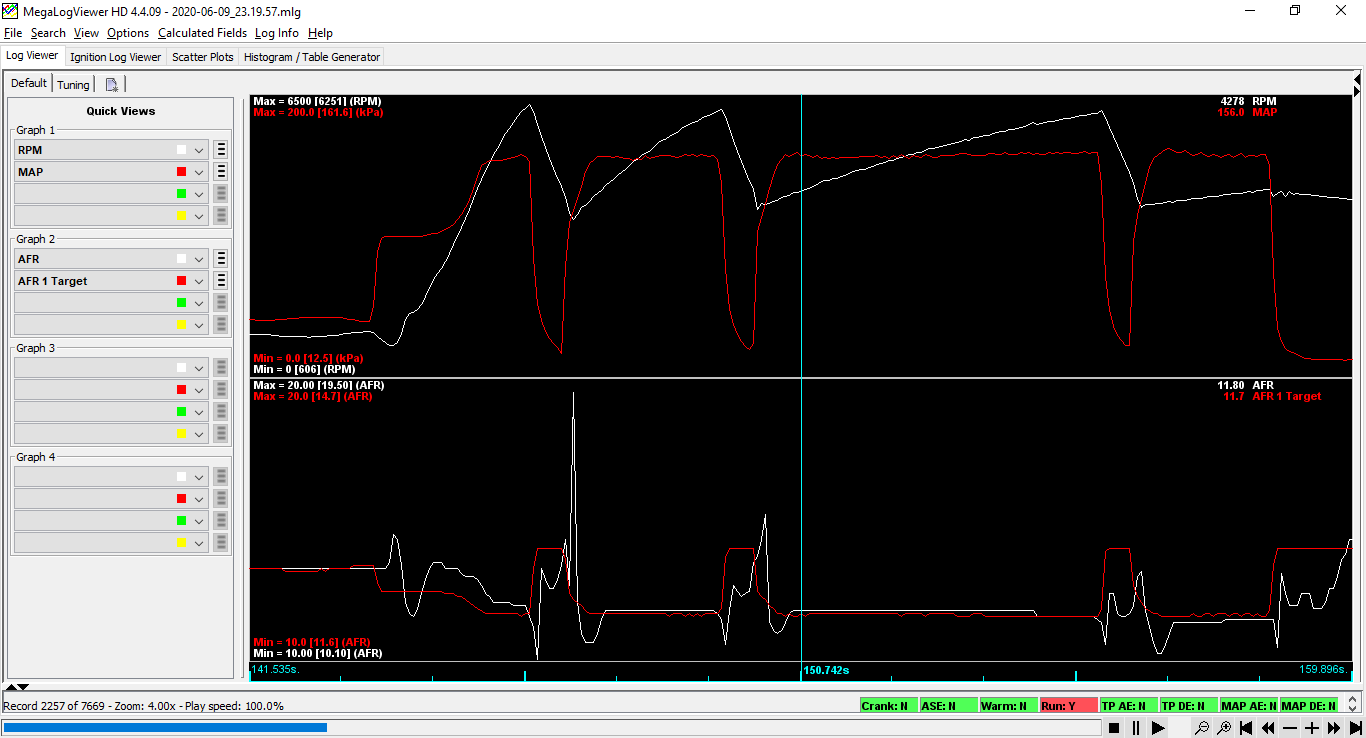

Here is a WOT run in all four gears, starting from idle in 1st gear:

In the bottom pane, the measured AFR and AFR target are superimposed on each other.

In 1st gear, the measured AFR is leaner than desired.

In 2nd and 3rd gear, the AFR is close to the target.

In 4th gear, the AFR is richer than the target.

This inconsistency in AFR does not cause a WOT driveability problem, but it nags at my sense of OCD.

I think that wall-wetting explains the difference between gears. When the injector wets the intake walls with fuel, the fuel stays on the walls for perhaps ~0.3 seconds before re-evaporating and being sucked into the cylinder. This causes a lag in fuel delivery between the injector and the cylinder.

In 1st gear, it takes about 0.3 seconds for the engine speed to increase from 5000 RPM to 5700 RPM. So at 5700 RPM, the cylinders are finally sucking in the fuel that was sprayed 0.3 seconds earlier, when the engine was spinning at 5000 RPM. Fuel flow at 5000 RPM (on this engine anyway) is less than at 5700 RPM, so the engine operates a bit leaner than desired.

I think I will try the "X-Tau" wall-wetting compensation feature of the MegaSquirt. In addition to making WOT better, I think (hope) it will make all other transient states better. For example, if I go to neutral while engine braking, the engine won't return directly to its 850 RPM idle. Instead, it will go lean and dip down to 750 RPM before the mixture stabilises and the idle returns to 850 RPM.

I could try to patch the idle return problem with a dashpot-type feature on the IAC, but it doesn't address the root cause which I suspect is wall-wetting.

A good video to watch:

https://www.youtube.com/watch?v=0ItkpVofKLw[This message has been edited by pmbrunelle (edited 06-10-2020).]

|

|

|

La fiera

|

JUN 10, 08:09 PM

|

|

Have you tried the "Time-Based Acceleration Enrichment" feature in MS? That's what I use to make my tip in and stomp throttles

nice and crispy. You can tune it by TPS or MAP or a blend of the two.

|

|

|

pmbrunelle

|

JUN 10, 08:33 PM

|

|

Yes, for now I use TPSdot accel enrich. However, that can only correct transients caused by a changing throttle pedal.

The AFR error in 1st gear cannot be corrected by TPSdot accel enrich, since the throttle is fixed at 100% during the pull.

I want to make the car run well enough that my dad could get in, start the engine, and start driving to work 5 seconds after starting, without stumbles or hesitation, like a new factory car.

I don't know if I will reach this objective, but that is the challenge I give myself, to tune this engine the best I can (for driveability). I think that wall-wetting compensation will help me reach this goal.

At some point if I can master the driveability aspect, then I may want to add the challenge of also tuning for fuel economy/pollution. But I am not there yet.

Edit to add: On my previous car, I used TPS-based acceleration enrichment. If I do exactly the same thing this time, then I won't be learning anything. If I don't learn new things with this project, then there's no point for me to own this project car. So I want to play with wall-wetting, because I might learn something.[This message has been edited by pmbrunelle (edited 06-10-2020).]

|

|

|

La fiera

|

JUN 10, 09:40 PM

|

|

| quote | Originally posted by pmbrunelle:

Yes, for now I use TPSdot accel enrich. However, that can only correct transients caused by a changing throttle pedal.

The AFR error in 1st gear cannot be corrected by TPSdot accel enrich, since the throttle is fixed at 100% during the pull.

|

|

In a turbo car I would use MAPdot instead of TPSdot to avoid the problem you have. It has the same problem in every gear

but it is more pronounced in first because the RPMs wind out quicker. If you make the enrichment based on manifold pressure

which varies even if the TPS is 100% it'll be way more responsive beacause you are giving it the fuel it needs as manifold

pressure raises with RPM. Then, when you get to the EAE you can find tune to perfection.

PS. I'm working on a EAE strategy for my engine also but I'm making sure all the other aspects of the tune are worked out.

|

|

|

La fiera

|

JUN 10, 10:03 PM

|

|

|

|

pmbrunelle

|

JUN 11, 08:52 AM

|

|

Yes, mapdot might work better on my car than tpsdot.

Is wall-wetting the only reason that acceleration enrichment is needed? I don't know of any other reason. For example, does direct injection need acceleration enrichment? I'd think not.

If wall-wetting is the only physical reason that acceleration enrichment is needed, then it makes sense that a wall-wetting scheme could be the only acceleration enrichment scheme, and it would be more accurate in compensating for wall-wetting.

mapdot/tpsdot could be added in afterwards to help mask any imperfections with the wall-wetting compensation, but it would be a band-aid.

I looked at some other videos from Andy Whittle too; he uses the datalogs and plotting features a lot![This message has been edited by pmbrunelle (edited 06-11-2020).]

|

|

|

Will

|

JUN 11, 09:10 AM

|

|

In a carb, when the throttle is opened aggressively, there's an amount of time required for the mass flow through the venturi to build enough that the venturi vacuum signal is strong enough to draw in fuel. That requires a mechanical means requires to add the fuel the delta airflow needs until the vacuum signal from the venturi catches up.

In a port injected engine, the throttle is some distance from the injectors, meaning that there's a delay between when the throttle opens and when the delta airflow arrives at the injectors and even more of a delay before that signal registers on the MAP sensor... so there needs to be a curve different than directly proportional to TPS involved in ramping up the fueling for snap throttle openings.

|

|

|

La fiera

|

JUN 11, 10:13 AM

|

|

| quote | Originally posted by Will:

In a port injected engine, the throttle is some distance from the injectors, meaning that there's a delay between when the throttle opens and when the delta airflow arrives at the injectors and even more of a delay before that signal registers on the MAP sensor... so there needs to be a curve different than directly proportional to TPS involved in ramping up the fueling for snap throttle openings.

|

|

That's why my injectors are located high in the runners. To have about the same time in TPS/Injection, litterally wall-wetting, heat absorption and to give time for the fuel to evaporate before being swallowed by the intake valve. All that equates to improved throttle response, cooler and denser charge and and fuel/air in vapor ready to combust.

|

|

|

Will

|

JUN 11, 11:05 AM

|

|

|

If you really want zero accel enrichment with good mixture quality, then shower injectors above throttle per cylinder is the way to go.

|

|

|

pmbrunelle

|

JUN 11, 06:33 PM

|

|

On the subject of mixture quality, I tried end-of-injection timing half-way through the intake stroke (i.e. with the intake valve wide open). The engine did not like to idle like that; it ran very rough.

The MS3's default end-of-injection timing is at TDC just as the intake valve is starting to open. That gave "good" idle quality.

More advanced timing values (on a closed intake valve) did not improve idle quality. It seems like the fuel vaporises rapidly after hitting the intake valve; more dwell time has no effect. The downside of too much advance seemed to be slower throttle response.

I suppose that with "better quality" injectors I might not have to spray on the barely-open intake valve, but I don't know what the spray of my Accel injectors looks like.

Rei, did you consider using a carburetor?[This message has been edited by pmbrunelle (edited 06-11-2020).]

|

|

|

|