|

| 4.6 Northstar Swap Project (Page 13/22) |

|

copperhens

|

JAN 17, 07:04 PM

|

|

What’s this?

Any ideas?

It’s an adapter for the throttle body for the cable to mount to. It has an o ring grove cut on the other side.

There is great throttle travel now. With an accelerator pedal, we were able to test putting it into gear. It does move forward and backwards under its own power. It won’t go into first. We haven’t adjusted anything trans-wise which is prolly the issue. Also, the new cooling system seems to now work with no leaks! The heater core lines heated up, and eventually the radiator got warm, and the fan turned on and off when needed and moves a ton of air.

|

|

|

copperhens

|

FEB 09, 07:47 PM

|

|

|

|

copperhens

|

FEB 09, 08:01 PM

|

|

I picked up some panels today in Houston from ccfiero350. It was awesome to be able to meet a Fiero person in the Southwest. Thanks for everything, Chuck! It’s an early IMSA that has all of the widebody panels. I’m dreading going back to Michigan because it’s subzero temperatures. This ‘88 is slowly but surely making a lot of progress.

[This message has been edited by copperhens (edited 02-09-2021).]

|

|

|

Will

|

FEB 09, 09:14 PM

|

|

| quote | Originally posted by copperhens:

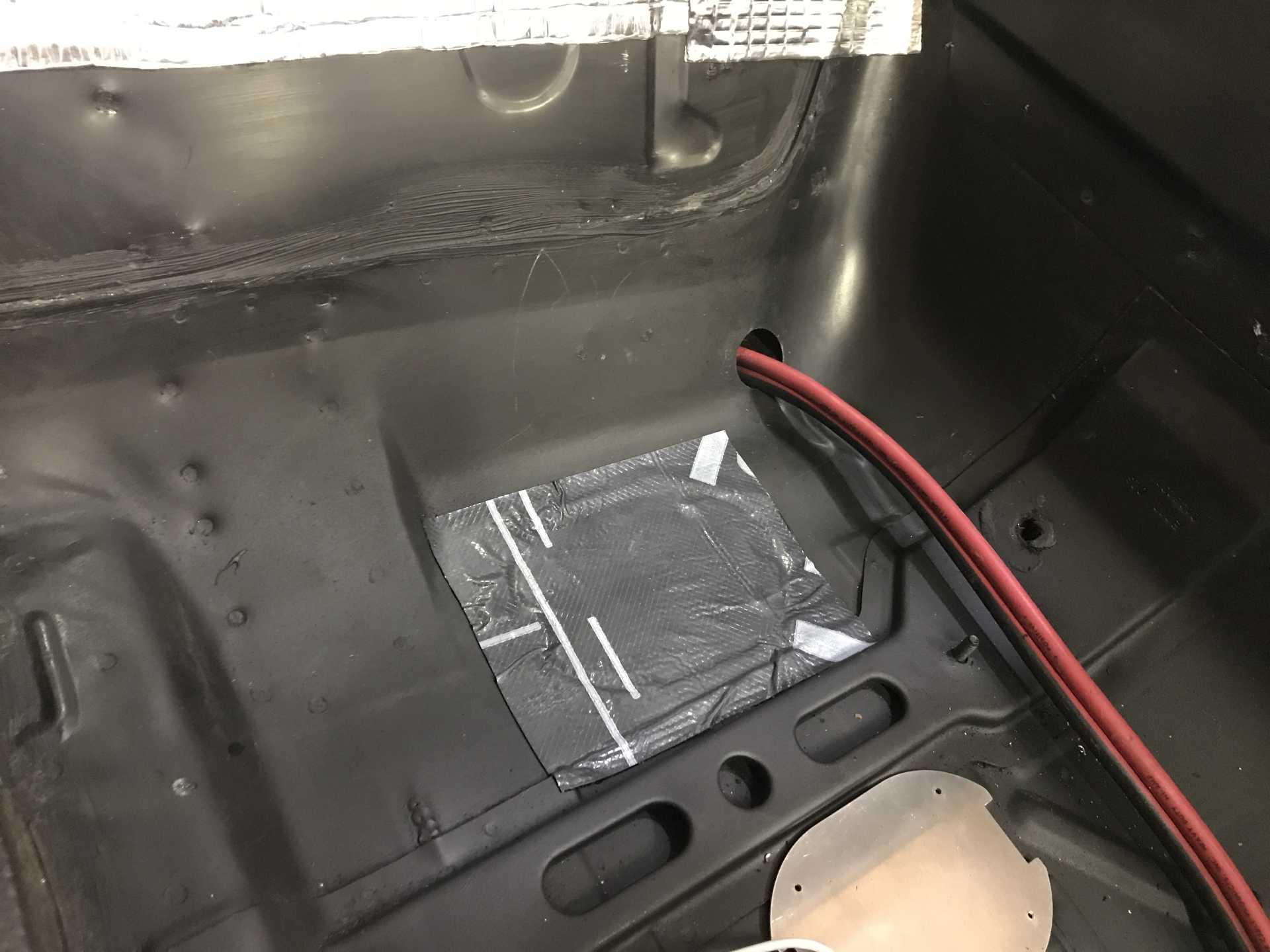

Rodneys floor plug in place. My drain plug was missing for whatever reason.

Roof tar to seal it up. Now that the holes were fixed, I could finished the sound deadening.

|

|

Did you ever grommet that hole?

|

|

|

copperhens

|

FEB 12, 04:50 PM

|

|

| quote | Originally posted by Will:

Did you ever grommet that hole? |

|

Yes, I did. I pushed the grommet out when I was prepping the area for the sound deadener, I just need to pop it back in.

|

|

|

copperhens

|

APR 04, 12:56 PM

|

|

|

|

copperhens

|

APR 04, 01:06 PM

|

|

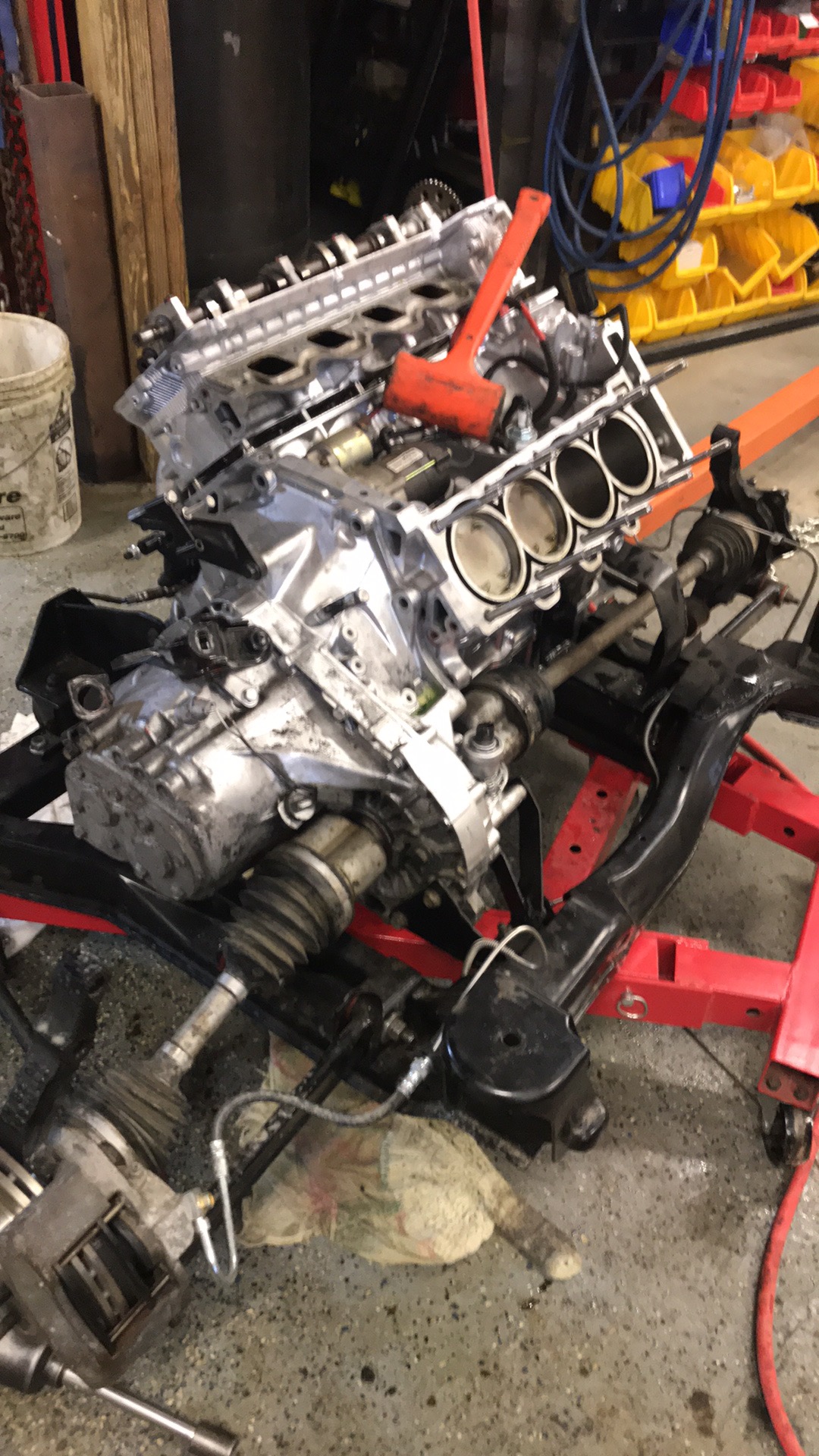

3/13/21

Brought the Fiero back to Mr. Eric’s, I appreciate him letting me use the lift. My boyfriend Paul and I got the engine dropped in just a few hours.

The tick came from the cam eating into this cam cap. This was the farthest point away from the oil flow.

The engine tear down begins.

So to recap, because a lot seems to have happened. I thought the Fiero was fine, and running. It developed a tick after sometime, presumably when the assembly lube wore out. There was no oil pressure to the top end. Why? The harmonic balancer bolt backed out, or was never torqued down. It had to be tighten in order to put the pulley back on, but regardless of if it was done or not, it was pretty loose and backed out somehow. This bolt put no pressure on the oil pump causing it to run very little, if at all. Should I have ran an oil pressure gauge? Yes. The gauge in the car never worked, and the car ran long enough we never expected anything of it. Obviously, when this goes together again we will verify there is oil getting to the car! Very frustrating, but the car isn’t toast yet.

|

|

|

copperhens

|

APR 04, 01:13 PM

|

|

3/14/21

Mr. Eric and I got the engine torn down in a day. We needed to assess the damage and check it the crank was good.

Good news. Everything seems to be okay. The main thrust bearing had .01 of wear on the driver side. The crank still felt smooth, and nothing was critical. All I need to buy to put there engine back together are new main bearings, and new rod bolts since they’re TTY. This engine could have been a lot worse with an oil pump that wasn’t working.

|

|

|

ericjon262

|

APR 04, 01:37 PM

|

|

Man, that's a bummer. I would look over the cam lobes and lifters very carefully. this may be a good excuse to put in a 06+ N*, with it's forged crank, 10mm flywheel bolts, better heads, 58x wheel ect.

Good luck.------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

Will

|

APR 05, 10:14 AM

|

|

| quote | Originally posted by ericjon262:

Man, that's a bummer. I would look over the cam lobes and lifters very carefully. |

|

Yeah, bigtime bummer... Check with a local dealership to make sure you have the most up-to-date parts. IIRC, there was a TSB on the balancer bolt & oil pump issue.

| quote | Originally posted by ericjon262:

this may be a good excuse to put in a 06+ N*, with it's forged crank, 10mm flywheel bolts, better heads, 58x wheel ect.

Good luck.

|

|

Easier said than done at the moment... I'm figuring out the engine management for that combo.

It has 11mm flywheel bolts.

The heads are not necessarily better on the roller cam engines. The intake ports are better but the exhaust ports are worse.[This message has been edited by Will (edited 07-26-2021).]

|

|

|

|