|

| 85 Notchie Build (Page 13/23) |

|

jdv

|

APR 03, 12:14 AM

|

|

|

Working on cars since a teenager I totally under estimated how big of a undertaking a bus was.

|

|

|

zkhennings

|

APR 10, 10:14 AM

|

|

I don’t have much to update for the Fiero, I am still waiting for the engine to come back from the shop, but I may move the Fiero to the garage soon. My youngest brother has been doing work to the middle brothers 02 Civic, and that is taking up space in the driveway right now as it is on jackstands. He has a sweet Eastwood tool for flaring lines and is making all new brake lines for the car. It has burst at least 3 since we have had it, other than that it is a sweet car, stick, vtec, 45mpgs, 85,000 miles. I have been helping him with that, we are replacing the front end control arms, bushings, ball joints, inner and outer tie rod ends, and endlinks. The car is getting driven by my brother’s friend out to cali soon where my brother lives. Once the Civic is done the Fiero will get moved.

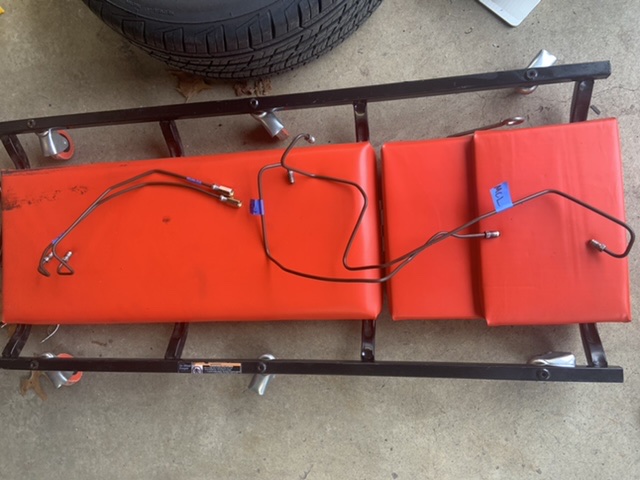

Some of my brother’s handiwork

I bought dew wipes for the Fiero from member silver 85 se and they look great, came in quickly too.

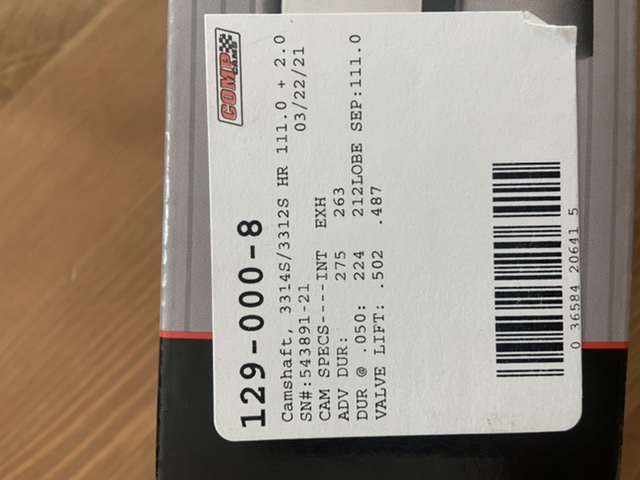

My cam came in too, and I was wrong, it does have a larger intake duration and lift than the exhaust.

I have also decided to get new roller lifters, I would be so mad if a roller broke and ate my cam and possibly trashed the rest of the motor. I can use my current lifters to size the pushrods for length and order the new lifters at the same time I order pushrods.

I have a big bin full of degreaser I have been letting the parts soak in, only the lower intake manifold is left to clean. I am planning to use Eastwoods engine enamel, it is 2 part and I always find 2 part paints are superior when it comes to longevity. I will probably go for the aluminum or cast iron colors, which are different shades of gray. I like gray because you quickly know if something starts leaking. I will take my oil pump apart soon too for inspection.

And in bus news, I have spent a decent bit of time stripping a camper that I knew someone was getting rid of, got a rooftop AC unit and a sweet propane setup including mini stove/oven, and collected all the hinges and latches and other bits that are mobile home specific. There was a really nice Dometic propane powered fridge freezer tower combo, but it was massive and will take up too much space unfortunately.

Edit to say that all my images are sideways from uploading on my phone, I will fix this later

Edit also to say that ericjon262 was nice enough to send me his dxf files for the LZ9 headers he has been working on, and suggest OSHCut to me for where to get them plasma cut. I got 3/8” 304 stainless and it came out to around $150 for the pair which was awesome, I was expecting more for 304![This message has been edited by zkhennings (edited 04-10-2021).]

|

|

|

zkhennings

|

APR 11, 04:58 PM

|

|

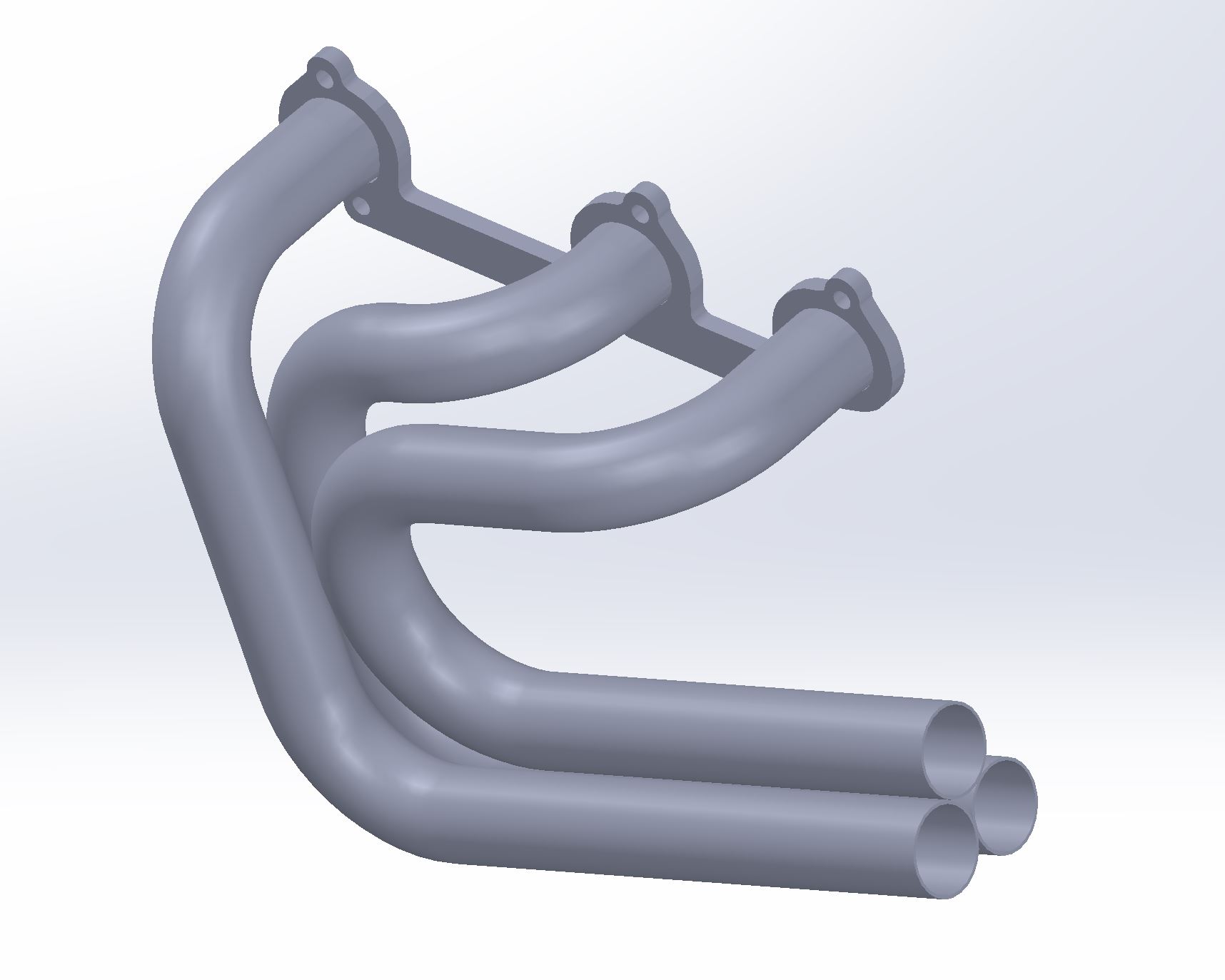

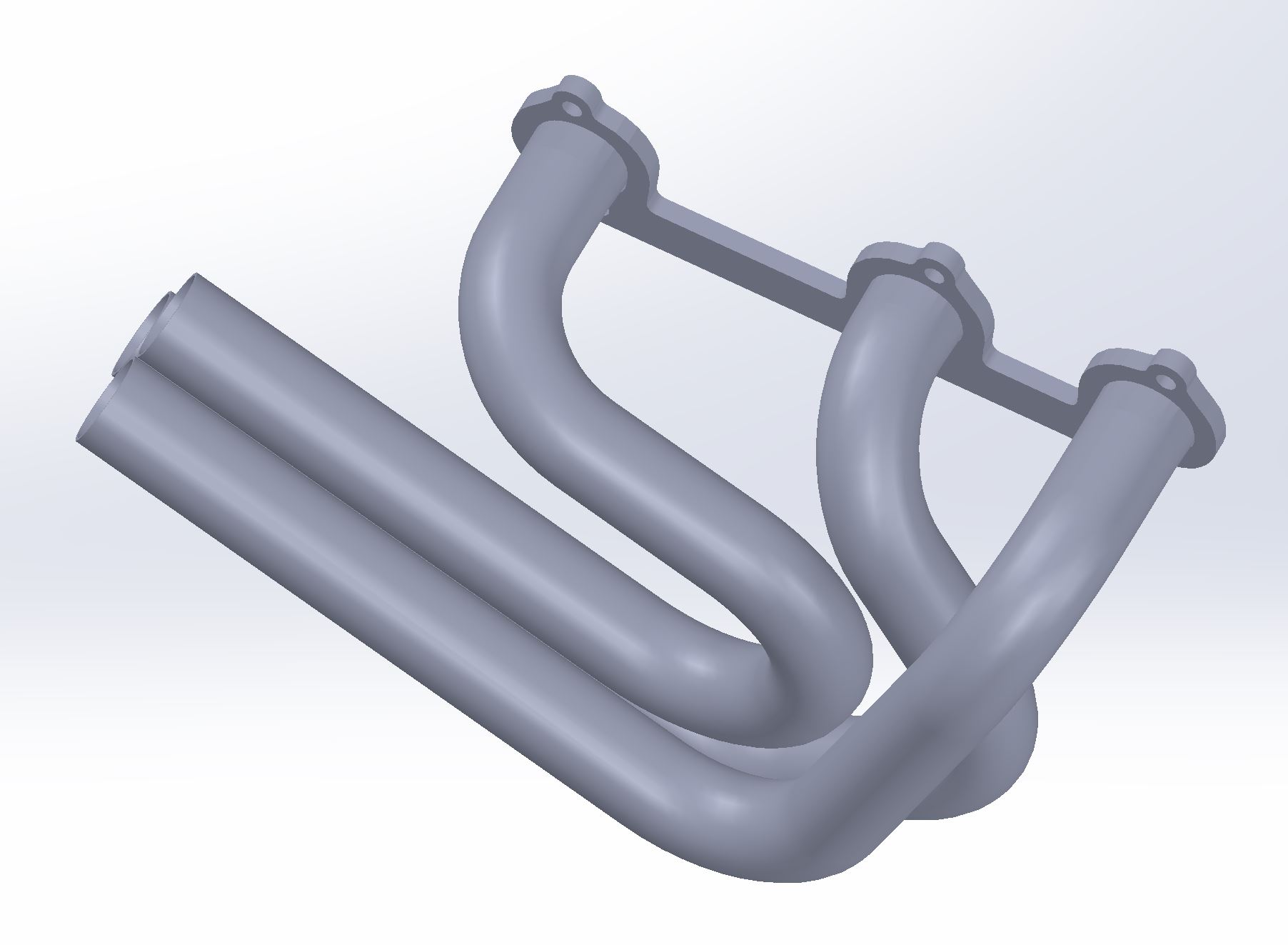

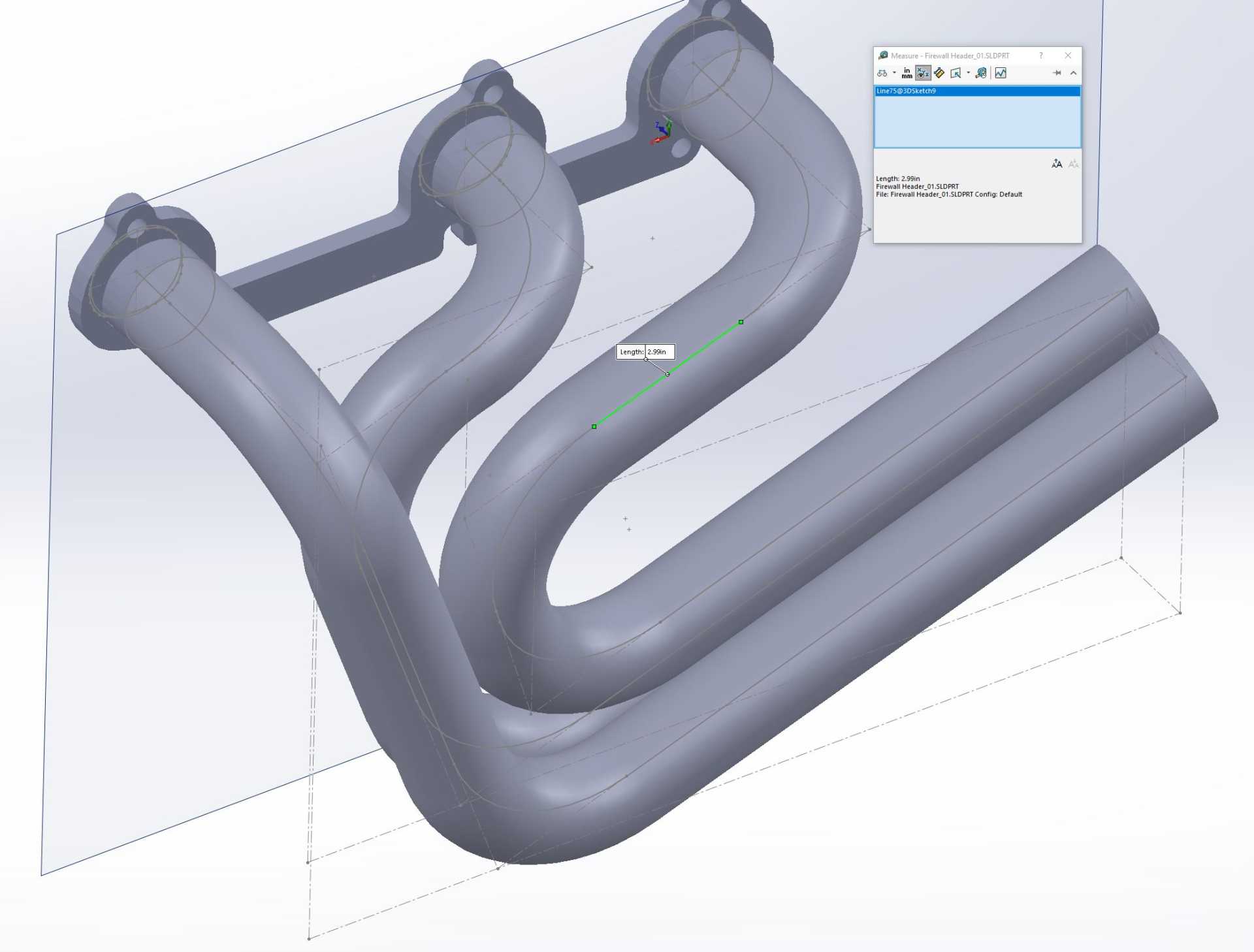

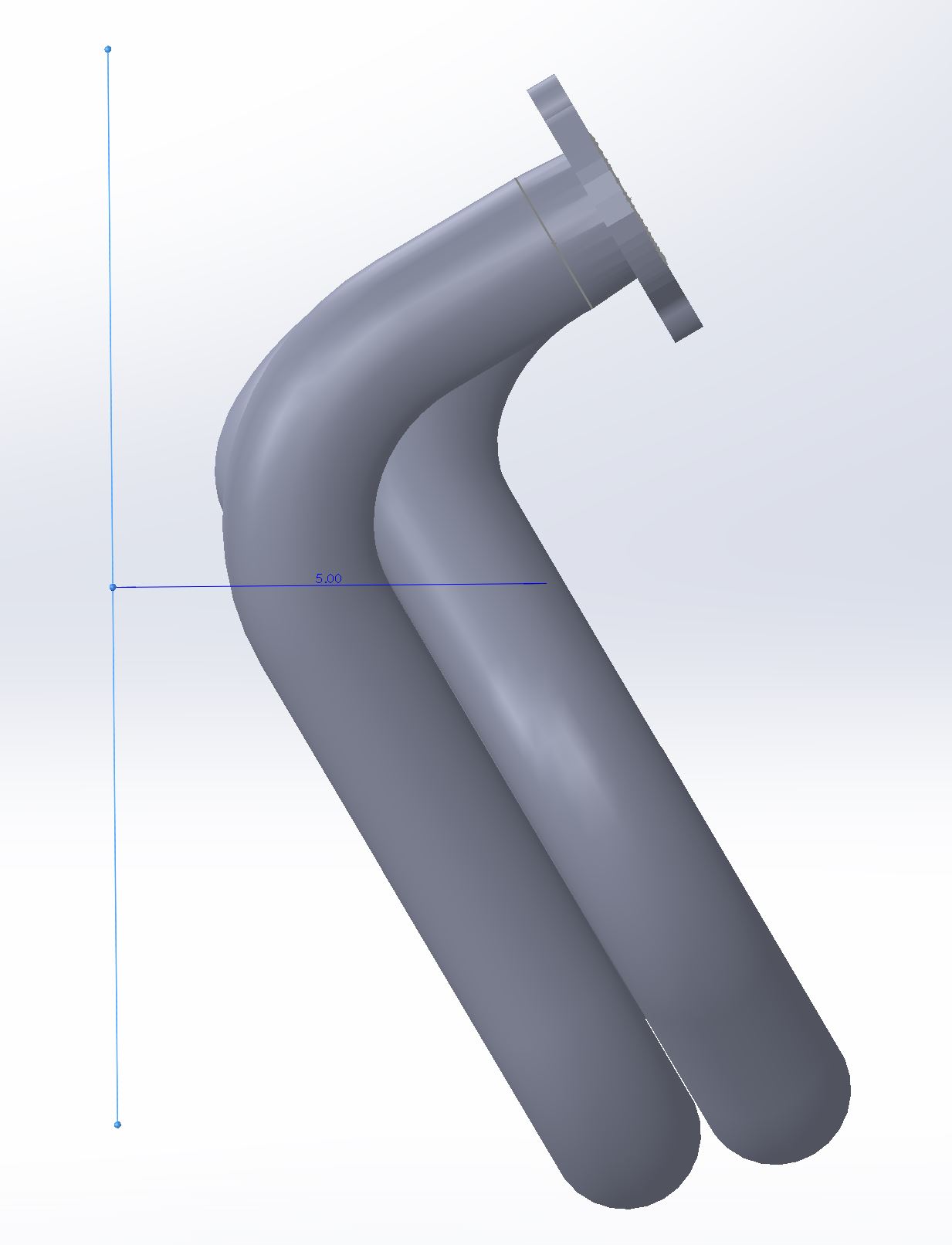

Using Eric's dxf I was able to mock up a rough set of headers. I imagine that I will need to make adjustments to the design if there are any components I need to clear. I know I will have to clear the back of the timing cover and the shift cables and throttle body on the firewall side headers, and the diff housing on the trunk side. These are 1.75" primaries and they are all within 0.2" of 28" long. I tried getting the headers to the same length as early on as possible while also minimizing sharp bends, leaving me flexibility to route the 3 straight tubes in different ways if I need to. It will be extremely easy to cut all the tubing to the exact shape and size necessary to make these as the majority of bends are 90*, and they are all the 2.63" bend radius of the tubing I have selected. I started by defining the tube that has the longest distance to travel. Both collectors will end up in the same place relative to the header flange. I think this will work out ideally for me but I need to do some mock up with the actual engine once I get it back. However this rough mock up gives me a good idea of exactly how much tubing to purchase and the quantity of bends I will need.

Firewall side headers

Trunk side headers

The headers should stay pretty tucked against the engine, I think they stick out max 6.375" from the head itself. I will have to check the engine bay for clearance once I get the engine mounted.

I intend to have an equal length Y pipe that runs over the transmission similarly to how my custom Y pipe was routed on my 2.8, I think I am just going to have it be 3" tubing like the rest of the exhaust.

If you think I will run into issues, let me know, I would like to get these more finalized so I can order material.[This message has been edited by zkhennings (edited 04-11-2021).]

|

|

|

ericjon262

|

APR 11, 11:18 PM

|

|

|

That's awesome looking! are you planning on having them mandrel bent so that all you have to do is weld them up? ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

zkhennings

|

APR 12, 06:05 PM

|

|

I intend to order a bunch of 1.75" U bends and 1.75" 4' long straight sections. 4 feet long to avoid additional shipping charges. I should need 8 U-bends total, but will probably order a couple more for unexpected bends.

I have a 3D sketch defining each primary, and it is a simple matter of seeing how long each section needs to be and cutting it. I can masking tape the headers together to get all the angles right. then tack it in place, and weld each primary tube fully individually. Then I will tack them to the header flanges and the collectors and weld everything fully.

I wish 1.75" carboard tube donuts with a 2.63" radius were a thing so I could mock this whole thing up with C.A.D. to check all my clearances. Maybe I can bend some wire to shape instead and slide a 1.75" wood disk with a hole in the center along it to see if I will have clearance issues.

|

|

|

pmbrunelle

|

APR 12, 06:22 PM

|

|

| quote | Originally posted by zkhennings:

I wish 1.75" carboard tube donuts with a 2.63" radius were a thing so I could mock this whole thing up with C.A.D. to check all my clearances. Maybe I can bend some wire to shape instead and slide a 1.75" wood disk with a hole in the center along it to see if I will have clearance issues. |

|

Something like 3/16" steel rod is easy enough to bend (and cheap), yet rigid enough to hold its shape. Can be tacked together for checking clearances.

Unless you also draw the engine bay in CAD, you'll have to do a mixed reality/computer-based approach.

|

|

|

jdv

|

APR 12, 09:15 PM

|

|

I read years ago to use flex tubing to make mock up headers. It's not that expensive.

ttps://www.ebay.com/itm/1-75-1-3-4-ID-x-18-Length-Galvanized-Flexible-Exhaust-Tubing-Pipe-1-5-Feet/164214857531

|

|

|

ericjon262

|

APR 12, 09:43 PM

|

|

I just went and measured my car, from the portion of the head closest to the firewall, to the firewall is about 7.75", and from the portion of the head closest to the trunk wall, to the trunk wall, is about 5", the firewall gets further away as you go lower, the trunk is relatively flat. in both cases the top of the head is closer, and the bottom further, but only by a small margin. My car is also probably not the best car to measure, as all of the mounts are custom, and it has an 88 cradle swap.

------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

|

|

|

La fiera

|

APR 12, 10:12 PM

|

|

| quote | Originally posted by zkhennings:

My cam came in too, and I was wrong, it does have a larger intake duration and lift than the exhaust.

|

|

That's a plus for you! In case you don't get to your power goals NA it'll work wonders with nitrous or turbocharging due to the reverse split pattern.

|

|

|

zkhennings

|

APR 13, 10:17 AM

|

|

| quote | Originally posted by pmbrunelle:

Something like 3/16" steel rod is easy enough to bend (and cheap), yet rigid enough to hold its shape. Can be tacked together for checking clearances.

Unless you also draw the engine bay in CAD, you'll have to do a mixed reality/computer-based approach. |

|

| quote | Originally posted by jdv:

I read years ago to use flex tubing to make mock up headers. It's not that expensive.

ttps://www.ebay.com/itm/1-75-1-3-4-ID-x-18-Length-Galvanized-Flexible-Exhaust-Tubing-Pipe-1-5-Feet/164214857531 |

|

| quote | Originally posted by ericjon262:

I just went and measured my car, from the portion of the head closest to the firewall, to the firewall is about 7.75", and from the portion of the head closest to the trunk wall, to the trunk wall, is about 5", the firewall gets further away as you go lower, the trunk is relatively flat. in both cases the top of the head is closer, and the bottom further, but only by a small margin. My car is also probably not the best car to measure, as all of the mounts are custom, and it has an 88 cradle swap.

|

|

Thanks for the input guys, some 3/16" steel rod would be great to nail the path down perfectly, it would be very easy to make sure all the angles I have bent are correct.

The flex tubing looks like it could be promising too, I am not sure if I could do as accurate of a job getting all the bends precisely where they would be, but it has the advantage of being the correct diameter tubing.

And thanks for the measurements! Using the measurements and making a mild assumption that the closest point to the trunk wall on the head would be around 0.75" above the upper exhaust manifold bolt holes, I put a plane at 30* to the header flange to account for bank angle and set it to 5" away from that closest point I defined.

It looks like I should have acceptable clearance to the trunk wall with my current layout. I have the distance the headers take their first bend laid out so that there is 1" of tube starting at the head available to blend the D shaped port into the 1.75" circular profile of the tubing. Then it is just a matter of starting the primary that is closest to the flange (the middle primary on both of my designs) immediately after that 1" of blend. I could always route the tubes in more complex paths to get around this constraint, but I would prefer not to in order to minimize bends and minimize the amount of welds required.

| quote | Originally posted by La fiera:

That's a plus for you! In case you don't get to your power goals NA it'll work wonders with nitrous or turbocharging due to the reverse split pattern.

|

|

My thoughts as well, I am itching to get this back together!

Machine shop is being slow as I guess 3 of their 5 guys are out because they are sick. I just hope they finish before the 22 as I will be getting my ACL surgery and will have a hard time putting the block into the backseat of the WRX/back on the engine stand once that happens. I already brought my C500 connector home to start rewiring/labelling it once I am stuck on the couch for a bit, I should bring my headlight motors home too to rebuild them at the same time. First order of business once I get the motor back is to install the cam and 2 valves with springs and get the pushrod lengths measured so I can order those and the lifters. Then I will paint the block and other parts, install the bottom end, and bring the small various components to cryo treatment facility.

Hopefully this week my brother and I finish our other brother's Civic, and then I will get the Fiero in the driveway and pull the cradle out to get ready to mock up the front engine mount.

|

|

|

|