|

| I bought another car (Page 6/12) |

|

gen2muchwork

|

JAN 25, 06:59 AM

|

|

pass. rear. My hone would not fit in the wheel well with any reasonable control. So out came that axle. I honed it up, and I think it cleaned up ok in the seal area. The pistons move smoothly, but I guess I'll know how well that worked when I step on the brakes (which will be a little while).

I should mention, this must have been apart before, as the axle front seal was beat up from a screwdriver, and the bearing grease is something other than factory.

It's all assembled it the rear now, but I need to focus on the parking brake for a minute. My understanding is that even when new, they don't work well. Mine has some binding somewhere along the line and is not releasing quite right, but applies itself sort of ok, which might be normal.

I flushed out the rear diff, No drain plug, No cover. So I had to pump it out which is super slow in the cold weather. The dif does seperate into halves, the back half has the axle tubes and pumpkin, the front mounts the motor, so It would not be very easy to seperate.[This message has been edited by gen2muchwork (edited 01-25-2018).]

|

|

|

Monkeyman

|

JAN 25, 10:17 PM

|

|

| quote | Originally posted by RWDPLZ:

I want the name and address of the engineer that designed that wiring. I want the name and address of the engineer that designed that wiring. |

|

| quote | Originally posted by gen2muchwork:

...Lucas electrical. |

|

Lucas. The prince of darkness. If you've ever had an older British vehicle, you'll know exactly what I'm talking about.

|

|

|

gen2muchwork

|

JAN 26, 07:05 AM

|

|

| quote | Originally posted by Monkeyman:

Lucas. The prince of darkness. If you've ever had an older British vehicle, you'll know exactly what I'm talking about.  |

|

Comparing it to an american car of a similar year, the electronics are terrible. even the turn signal switch uses open contacts. Nothing at all protecting any of the assembly besides the steering column cover. If it had a contact, its out in the open and corroded. It's a process of cleaning I will be repeating throughout the life of this vehicle. Sooner or later I'll want to replace that darn turn signal stalk because it does not return after a turn like it should. For some reason those poorly designed stalks are not an inexpensive part, no matter how cheap they make it. There is not an insulated spade connector anywhere, although some of the lighting uses insulated bullet connectors that make a bad connection, and while prevent direct shorts, have no weatherproofing at all. Would I buy a british car after this experience? you bet! But I'd assume wiring updates and engine swaps.

Now, I'm working on the Parking brake. Another interesting design. It uses a pull handle under the wheel, similar to some other vintage cars. the cables are a little sticky, but again with the poor design. Every cable pulls at a funny angle. not one pulls straight. The only springs that retract the cable are the shoe springs. essentially, when brakes are adjusted the cable has to pull less than an inch to engage the brake. with no return springs, that leaves my cable all floppy. When I pull the lever, It's all like 2" of nothing then 1/2" of yank as hard as you can. I could see how the handle could brake on this system. Maybe I'm missing something somewhere spring wise. Sometimes I wish I had worked in the maintenance shed at the golf course instead of caddying as a kid. I'd have a better grasp of golf cart brakes. From what I can tell this is very similar to a cushman truckster front brake system on all 4 wheels.

The important thing to consider with the parking brake, is that I have reverse drive and neutral. No park. Without it when the wind blows the car moves. There is no leaving it in gear, no engine compression. So it is more important than any parking brake I have ever had. Also, a dragging brake is worse in this than normal, I have 6hp and limited power. Dragging brake might make me lose top speed, or range, or worse overheat my motor. Not so big a deal on a more powerful gas powered car, but a big deal here.

There must have been a spring somewhere along the line. The smart place would be at the end of the line at the brake actuator lever on the drum. It has two holes, one for the cable, one for? So maybe I can rig something, I have a big box of odd brake springs I saved throughout the years. I see many of the golf cart brake cables have an integrated spring along the cable. I can't add that, but maybe the whole rear cables could be substituted. 2 options to consider there. I'll figure something out.

Another thing to note. If you have good eyes you may notice that my rear pass. leaf spring has 2 leaves, but the drivers has only one. Not sure what happened there, but I doubt it was intended to be that way. For fun, there is no bump stop so if one was to break... the wheelwell/tire is the bump stop. not the best.[This message has been edited by gen2muchwork (edited 01-26-2018).]

|

|

|

Monkeyman

|

JAN 28, 06:34 PM

|

|

| quote | Originally posted by gen2muchwork:

... that leaves my cable all floppy.

|

|

Not sure I would announce that to the world, especially if you ever plan on another date.

|

|

|

gen2muchwork

|

FEB 06, 07:30 AM

|

|

| quote | Originally posted by Monkeyman:

Not sure I would announce that to the world, especially if you ever plan on another date.  |

|

lol

So, I got side tracked repairing a valve body on my wifes new edge which was successful, but I didnt get far on citicar.

Here is the pass. front brake assembly.

I need to order shoes. these ones are no good for front brakes.

You might notice the brake spider up front comes off easy compared to the back, but...

It is slightly different! The bore in the center is larger. This part is not available so If I cant hone them, I have to replace with a rear, then machine it. Yikes. This side looks pretty good, the boots are still there.

On a side note...

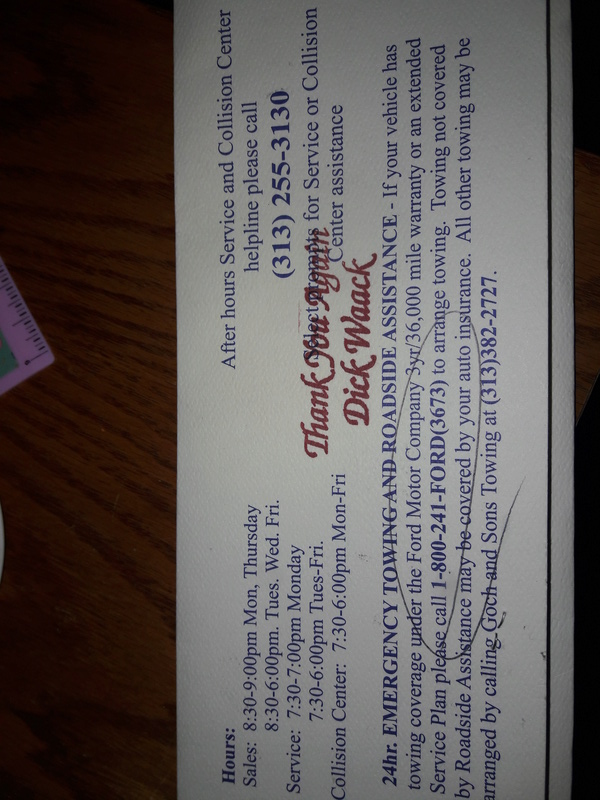

The Edge, On the paperwork in the glove box. Look at this guys name!

|

|

|

gen2muchwork

|

FEB 07, 07:00 AM

|

|

All disassembled.

bore looks great to hone. These fronts sure are easier.

|

|

|

LitebulbwithaFiero

|

FEB 08, 12:08 PM

|

|

Easy is good

|

|

|

gen2muchwork

|

FEB 14, 10:08 AM

|

|

My wife texted me yesterday to let me know my brake feet came in. lol.

So, now I have new SHOES on the front, and have rebuilt the wheel cylinders. The drivers side was pitted up kinda bad. I'll find out soon if I had to hone it too much... It cleaned up, but took more honing than I would have liked.

Next.... master cylinder and bleed.

After that? Idk I think it should be ready to roll at that point. I cant do any body work until it warms up a little, and I have a few cracks to continue fixing but should be ok to drive in the dry weather. Electric car plus water leaks could present a problem.

At this point in the build, I'm doing the sad thing. It happens an all my stuff as I near completion, I get sort of sad-happy when the project nears completion and I realize I don't have much longer to spend all night messing around. I'll get over it when I start driving it, and bbq, beer, car show season starts.

|

|

|

RWDPLZ

|

FEB 14, 10:26 PM

|

|

| quote | Originally posted by gen2muchwork:

My wife texted me yesterday to let me know my brake feet came in. lol.

|

|

My mother still calls tires 'wheels' I stopped trying years ago.

I much prefer enjoying the end result to the actual working on the car.

|

|

|

gen2muchwork

|

FEB 20, 04:07 PM

|

|

Batteries are expensive. I'm plated and insured now.

Had to replace the brake light switch

It fits some 50's Chryslers and Fords. Hydraulic pressure brake light switch. I can step on the pedal standing next to the car and see the brake lights it's so short lol

|

|

|

|