|

| Carbon Fiber or FG sunroof panel? (Page 1/3) |

|

mono

|

MAR 07, 04:44 PM

|

|

|

Is there a Carbon Fiber or Fiberglass sunroof panel available that replaces the heavy OEM glass? It would be a direct replacement, latch, hinges, etc.

|

|

|

hyperv6

|

MAR 07, 04:56 PM

|

|

|

|

Fiero Vampire

|

MAR 07, 05:50 PM

|

|

|

There used to be a company that made a fiberglass one, but they went out of business or just stopped making them (can't remember), I was lucky to buy one in the Mall you could try doing a WTB post and see if someone who had bought one might be willing to sale but if I recall they didn't sale/make many.

|

|

|

IMSA GT

|

MAR 07, 08:53 PM

|

|

| quote | Originally posted by Fiero Vampire:

There used to be a company that made a fiberglass one, but they went out of business or just stopped making them (can't remember), I was lucky to buy one in the Mall you could try doing a WTB post and see if someone who had bought one might be willing to sale but if I recall they didn't sale/make many. |

|

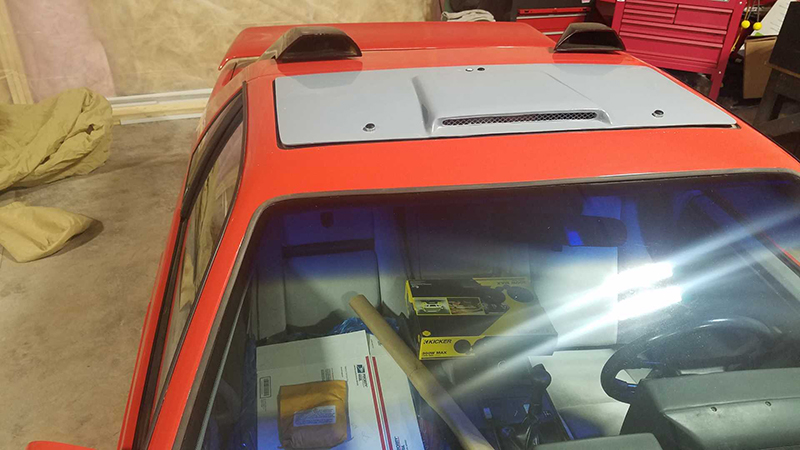

You are correct. Jimmy with Fierofiberglass used to make them. He also made one with a non-functional scoop:

[This message has been edited by IMSA GT (edited 03-07-2022).]

|

|

|

Australian

|

MAR 08, 03:30 AM

|

|

|

Looks like you need to customize it to fit I wouldn't suggest anyone buy one that couldn't make it. Don't buy body parts unless you can do body work.

|

|

|

Orig88GT-NC

|

MAR 08, 01:52 PM

|

|

I just made my own. Made a one time mold from the original sun roof glass and cast a fiberglass one. Hardware/Nuts are bonded into the panel, to attach the Tabs and Latch...Now I can swap between the glass panel or the the fiberglass one.

|

|

|

Australian

|

MAR 09, 04:42 AM

|

|

| quote | Originally posted by Orig88GT-NC:

I just made my own. Made a one time mold from the original sun roof glass and cast a fiberglass one. Hardware/Nuts are bonded into the panel, to attach the Tabs and Latch...Now I can swap between the glass panel or the the fiberglass one.

|

|

Great fitment did you paint inside or use a liner.

|

|

|

mono

|

MAR 09, 05:47 AM

|

|

|

Orig88GT-NC...That's exactly what I was looking for! Very clean. Would love to see any build photos on how you did it, fabrication details, etc. [This message has been edited by mono (edited 03-09-2022).]

|

|

|

Orig88GT-NC

|

MAR 09, 09:00 PM

|

|

| quote | | Originally posted by Australian: Great fitment did you paint inside or use a liner. |

|

I did paint the underside (Dark Gray) to sort of match the look of other OEM panels on the car... ie. underside of Hood, Rear Deck or Sun Roof opening.. But I did fabricate a new Sun Shade panel covered with the same Headliner material to give it a more finished look.

Fabricated Sun Shade

Headliner.. It's a Light Tan Suede material.

|

|

|

Orig88GT-NC

|

MAR 09, 10:26 PM

|

|

| quote | Originally posted by mono:

Orig88GT-NC...That's exactly what I was looking for! Very clean. Would love to see any build photos on how you did it, fabrication details, etc. |

|

I will tell you how I made it ......BUT

---------------------------------------------------------------------

DIS-CLOSER

• I do not have a large budget, so many methods or techniques I use maybe a bit unorthodox, but they work for me. My methods may not be the only or the best, but the results are of good quality and appearance...

• Since the budget is low, What I do have is Time & Patience and I am not afraid of making mistakes and starting over.

• I only fabricate parts that I can not find for sale... or have never been created before.

• Since the projects I make take ALLOT of time, I will NOT produce them for sell. They would be way to expensive and for a limited market.

• I enjoy designing and fabricating and do allot of it ....

• I know that everybody doesn't have the same skills, nor the patience.... but some have an interest and desire to try, and I'm willing to help...

---------------------------------------------------------------------

I didn't take allot of photos during the build, I think, I didn't expect the panel to come out right the first time...

HOW I MADE IT:

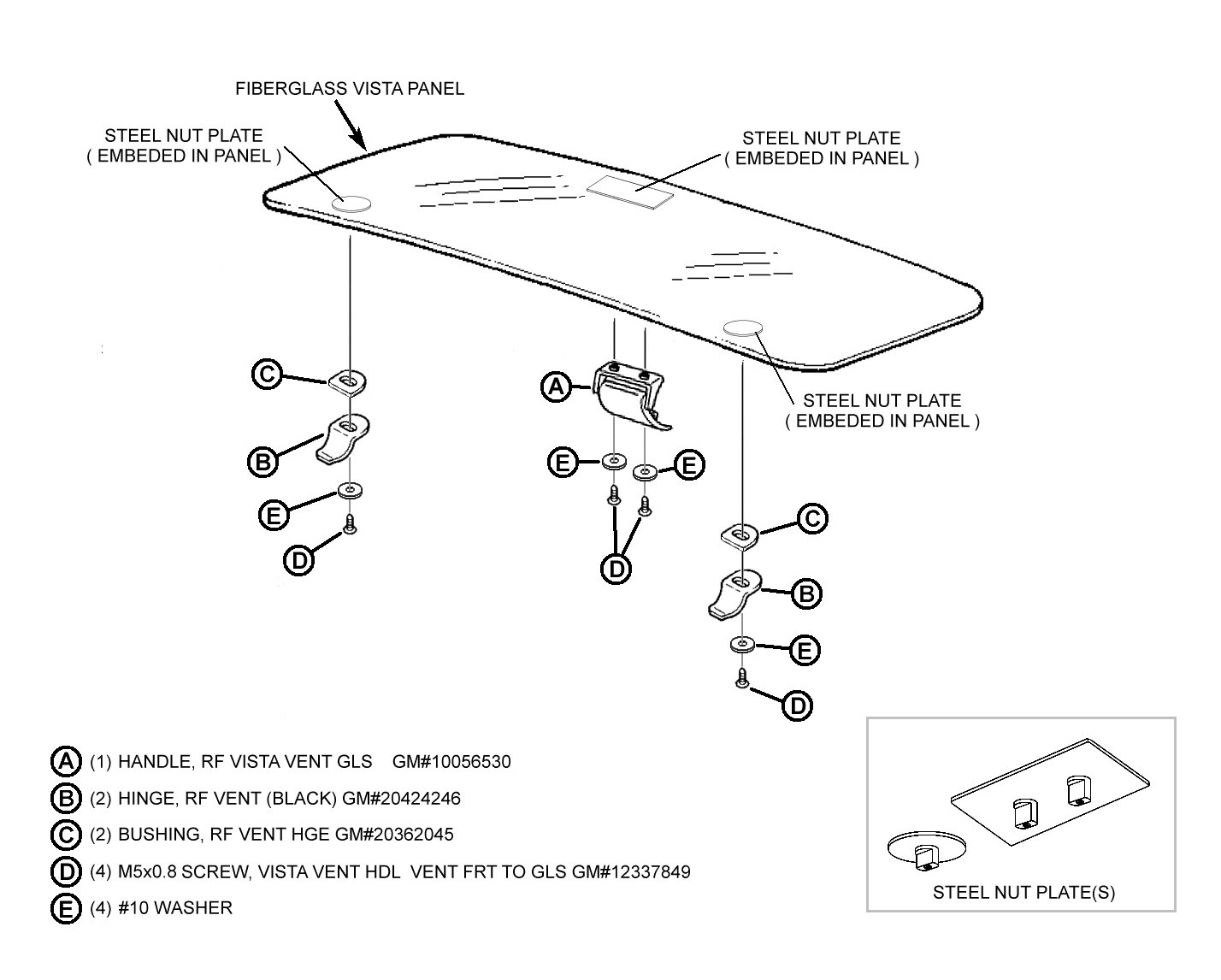

● The first thing I did was obtain the hardware... Latch Handle/ Tabs .. and make some steel nut plates to embed into the fiberglass.

One of the Nut Plates

Setup

● Next I made a shallow box out of wood that would fit the Glass Panel.

● Taped off the holes in the Glass with some painters tape and applied several coats of paste wax to the top surface of the glass.

● Poured Plaster of Paris into the Box and laid the Glass Panel into it gently. Then let it sit for about a week.

● Removed the Glass carefully. Leaving a perfect impression of the panel.

Fiberglass

● Mixed about a Qt of Fiberglass Resin and put down (2) layers of Fiberglass Mat... While this was starting to set, I positioned the fabricated Nut-Plates onto the panel AFTER I applied painters tape to the stud portion (to prevent resin from getting onto the shaft or threads).

● Mixed up another 2-3 Qts of Resin and applied about 10 Layers of Woven fiberglass in alternating directions(allowing the Nut-Plate Studs to poke through) until I achieved the same thickness as the original glass panel.

● I let this set for about a week... to help eliminate warping.

● After a week I carefully pried it from the mold.

● Trimmed and sanded the edges, touched up any little defects with spot filler( Bondo wasn't needed). Primed with a Urethane Sandable Primer and prepared for paint

Hope this helps.

I can take some better pictures if your interested

Bob

|

|

|