|

| Arraut Drop Spindles, another issue (Page 1/2) |

|

Larryinkc

|

JUL 12, 03:31 PM

|

|

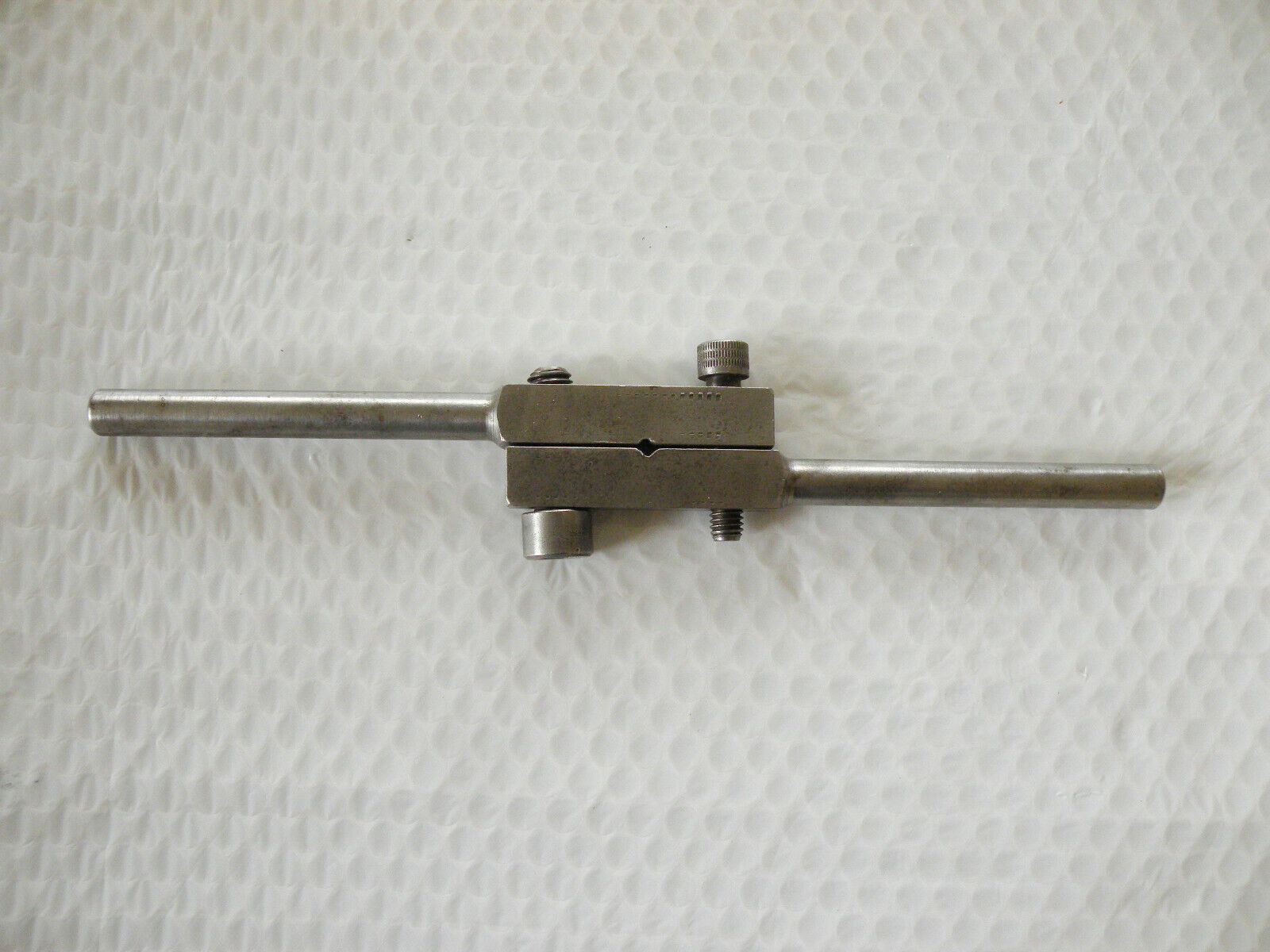

After the recent posts about Arraut suspension parts I could not drive my car without wondering if one of my front wheels was about to fall off. I have their tubular upper and lower A arms and drop spindles on my car.

I ended up taking my car to a local shop and asked the owners to look at the front suspension setup as if they had just acquired the car. They both have many years of experience building and servicing all manner of performance and race cars. They said that the A arms looked good but recommended taking both spindles off the car, removing the powdercoat and having them magnafluxed and then beefing up some of the welds. When I installed the setup I was a bit concerned with the appearance of some of the welds on the spindles, the A arms looked OK, probably not done by the same welder.

When I removed the spindles, much to my surprise, I found that the lower ball joint nuts weren't tight. I know that they were tight when I installed them but due to their design my torque wrench wouldn't work. After both spindles were off the car I found that the taper on the lower ball joint mount didn't match the ball joint stud taper, probably a bit more than 1/32" larger at the bottom, something I never thought to check. I put in new lower ball joints and the stock spindles. I can drive it now without worry, also an annoying, occasional rattle that I could never find the source of is gone.

My setup did not have any provision for bumpstops so while I was working on it I found a pair of Energy Suspension bumpstops that worked out pretty good. I mounted them on the lower A arm behind the sway bar links. They hit the factory upper bumpstop bracket when the tire is about 3/4" from the inner fender.

Energy Suspension part # 9.9150G

|

|

|

Raydar

|

JUL 12, 07:05 PM

|

|

Good find. Glad you didn't get hurt, before you found all that stuff

.

I'm guessing you have an 88, since those look like 88 bumpstops.

I ended up cutting one coil from my 88 front springs, and cutting the "points" off my bumpstops.

|

|

|

sourmash

|

JUL 12, 07:37 PM

|

|

|

Not sure how important it is, the loose ball joint. I had a Mazda 626 that the ball joints needed a little tack weld to tighten up.

|

|

|

Larryinkc

|

JUL 12, 10:34 PM

|

|

|

The ball joint wasn't loose in the control arm, it is loose in the spindle. The tapered hole in the spindle does not match the taper of the ball joint stud. I decided it would be better to put the stock spindles back on, lower it with the coilovers and just deal with the lower A arm angle that results.

|

|

|

Australian

|

JUL 20, 08:40 AM

|

|

|

You can achieve all the lowering you need without drop spindles.

|

|

|

Spadesluck

|

JUL 20, 04:44 PM

|

|

| quote | Originally posted by Australian:

You can achieve all the lowering you need without drop spindles. |

|

Very true, but in theory a drop spindle will lower the car but not change any of the geometry. "If" they are built correctly the are ideally the better way to go. That is the big "if" though.

|

|

|

fieroguru

|

JUL 20, 07:46 PM

|

|

| quote | Originally posted by Spadesluck:

Very true, but in theory a drop spindle will lower the car but not change any of the geometry. "If" they are built correctly the are ideally the better way to go. That is the big "if" though. |

|

Check the definition of scrub radius and think about how dropped spindles will impact it slightly.

|

|

|

Spadesluck

|

JUL 22, 02:27 AM

|

|

| quote | Originally posted by fieroguru:

Check the definition of scrub radius and think about how dropped spindles will impact it slightly. |

|

ughh, its always something. haha

|

|

|

Neils88

|

JUL 22, 09:53 PM

|

|

|

I have the coilovers and drop spindles from Arraut. But I suspect I'm going to go back to the stock 88 spindles. After everything I've read on PFF, I just don't have any confidence in the Arraut parts anymore.

|

|

|

qwikgta

|

JUL 22, 11:00 PM

|

|

| quote | Originally posted by fieroguru:

Check the definition of scrub radius and think about how dropped spindles will impact it slightly. |

|

I thought that if the dropped spindle maintains the same kingpin angle and there is no offset change, then the scrub radius is the same right? I guess it may change were the two cross, it would make the location were the two cross to be below the contact patch. What does using a lowering spindle do that is different than using a lowering spring, don't both do the same thing to the scrub radius?

|

|

|