|

| World's slowest Fiero/Quad 4 Swap (Page 44/51) |

|

Quadfather

|

FEB 18, 07:30 PM

|

|

|

|

Quadfather

|

FEB 19, 08:34 AM

|

|

|

|

Quadfather

|

FEB 19, 07:24 PM

|

|

|

|

Quadfather

|

MAR 19, 06:56 AM

|

|

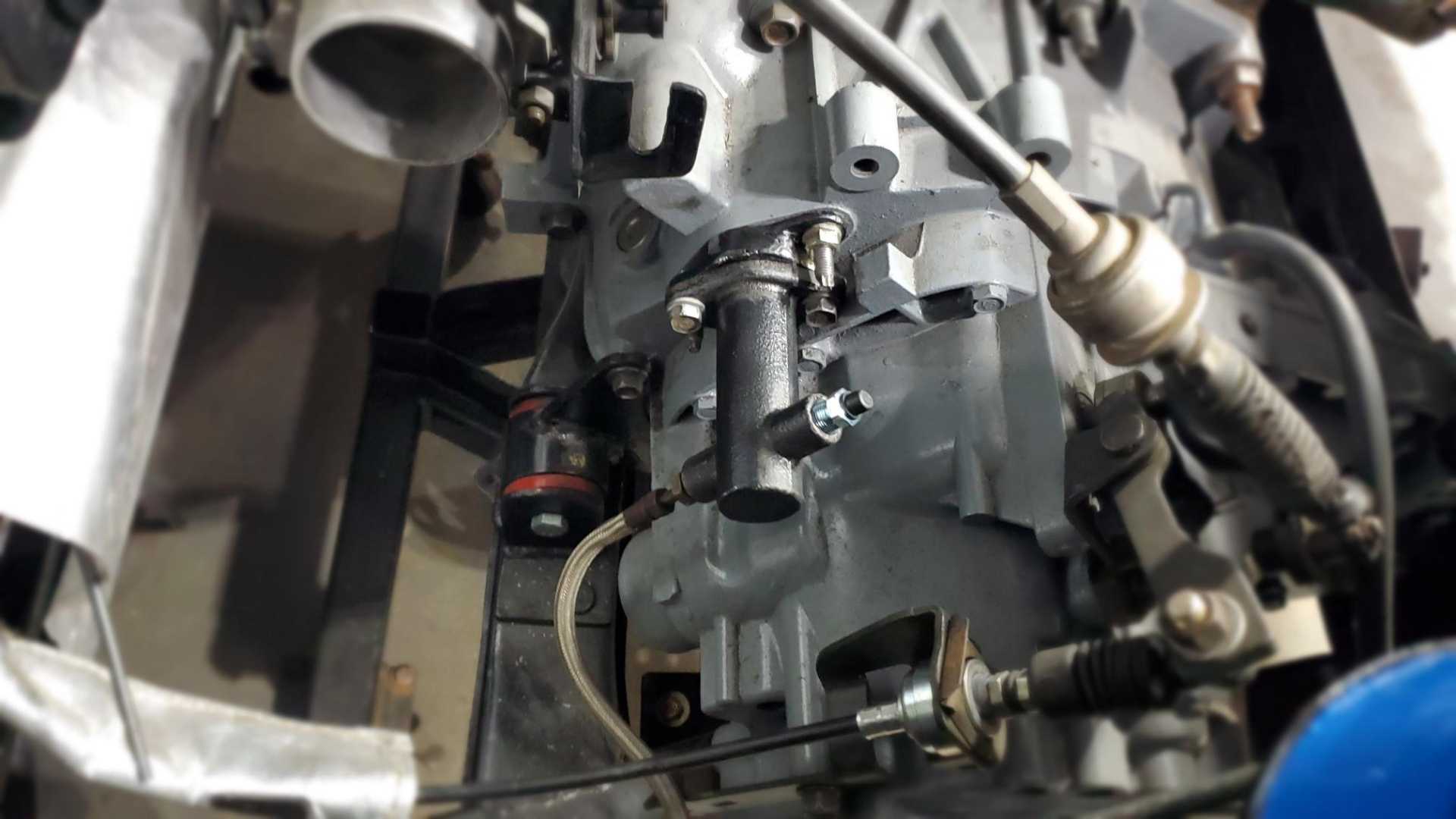

Maybe I’ve got the clutch slave sorted out. Realized the second attempt at an adapter was way too big. It would space the slave piston so far away from the clutch fork lever that the lever would not move far enough to release the clutch.

On Sardonyx’s build, he used a machined spacer that looks like it’s a half inch thick. I cut mine up and started over. The mounting holes have to be clocked because of the studs on the transmission.

I was aiming for exactly a half an inch in depth, but it’s just a bit deeper than that.

The problem is the adapter has to be narrow enough to fit in the space next to the transmission case, but wide enough for the rubber boot on the slave cylinder rod. When I first mounted the setup, the adapter pinched the boot, so I used a die grinder to open up the hole even more.

|

|

|

zkhennings

|

MAR 20, 12:53 PM

|

|

|

Nice work! What is still left to do before a test drive?

|

|

|

Quadfather

|

MAR 20, 07:01 PM

|

|

Well, let’s see:

-Engine harness/battery cables

-Engine coolant hoses/expansion tank

-Ignition coils (not sure if the parts from my Beretta still work)

-Thermostat housing

-Rear hubs & brake pads

-Reassemble rear suspension

-Coolant/engine oil & filter/transmission oil

I’m probably missing something obvious.

That would be to try to get it running. Before driving it I really need to buy tires. The tires that are on it came from the salvage yard’s $11 tire sale eight or nine years ago just to be able to move it around.

I find it more difficult to stay focused these days. Maybe it’s a side effect of getting older, maybe it’s just being busy with work and other parts of life. Physically it’s much harder, too. Weekend before last I had to replace the oil cooler lines on my Silverado. Without access to a lift, getting up and down from the floor and lying on my back to work on something is just hard. Anyway, aging isn’t for wimps.

I will likely take a week of vacation in the next few weeks to get as much done on the car as possible. My son has decided not to take a job out of state and his new knowledge of circuitry and solder will be a big help.[This message has been edited by Quadfather (edited 03-26-2023).]

|

|

|

Quadfather

|

MAR 26, 07:33 PM

|

|

|

|

Quadfather

|

APR 12, 08:18 PM

|

|

More progress, but few photos. Discovered a hole in the passenger fender liner so I used plastic from the original bottom support from the front fascia to make a patch and melted it on with a heat gun.

I’ve been working on the passenger headlight assembly, the other fender liner and repainting the underside of the deck lid. I’m waiting for new rear hubs to arrive to reassemble the rear suspension.

I’m hoping to modify the deck lid hinges this weekend to accept struts, then will remove the hood and repaint its underside. Lots of minor jobs to complete, then will be ready to pull the engine and cradle out and work on the wiring harness.

|

|

|

Quadfather

|

APR 16, 09:21 PM

|

|

|

|

82-T/A [At Work]

|

APR 17, 02:27 PM

|

|

Coming along!!!

Honestly, the Quad-4 is one of my favorite swaps. One day, I'd like to do a TwinCam LD9 swap into a Fiero... but it's possible that time has come and gone (fewer Fieros, fewer LD9s available). I was thinking I could use an ECM / harness from a 1995 vehicle (pre-OBD2), just for the ease of it. Do the "secret cam swap" as they say, and enjoy the car. I know the performance of a relatively stock LD9 wouldn't be amazing, but I like the smoothness of the LD9 (with the counter-balance shafts), the fuel economy, and the better performance than the V6 with the ~100 less pounds using the 5-Speed than a V6/60 + automatic.

|

|

|

|