|

| LS4 / F40 Swap #2 - fieroguru (Page 4/21) |

|

fieroguru

|

APR 17, 10:44 AM

|

|

| quote | Originally posted by E.Furgal:

I like this....

Thanks for doing this..

One thing I'd do off the bat is move the coil s (packs) off the valve covers.. just for looks.... grind down the stands and then paint the v/c red..

They do make covers to hide the coils under them (fake v/c's) but I'm thinking trapping the coil heat isn't a great idea

I know you listed under ground rules, to learn about the genIII ECU over the other type..

but the ECU type you used in your 1st swap.. how hard is it to program, tune, adjust as you add /change/update the set up?? and if it's not that hard to do, from the eyes of a newbie (not a person that can tune a g.m. ls tune in their sleep) .

What would the pro's and cons be of using the factory ecu over say.. the holley H/p ecu..

|

|

However, smoothing the valve covers isn't that simple... when you grind down the stands, you are left with holes in the valve cover that need to be welded up. Welding aluminum is not in the skill set of most DIY, so that isn't the direction for this swap. Simple, relatively inexpensive, and repeatable by others.

This swap will use the E40 ecm from the (05-06 LS4s). This ecm is quite fast and advanced, but it still uses a traditional VE table for tuning and isn't as reliant on the BCM.

The E67 (07+) ecm on my first swap was developed to enable VVT and GM switched from using a VE table to a series of coefficient equations. This used to make it tougher to tune VE, so many just ran MAF only. Now HP Tuners has virtual VE tables that make it easier to tune. The E67 is still much more reliant on the BCM for the brake position switch (case learn, cruise control, etc), which can complicate the swap.

I am not much of a fan with the aftermarket ecms. No aftermarket company puts in the same level of R&D and reliability testing as GM does with their ECMs.

I found the learning curve to be a bit steeper to understand and learn how to edit the scanner program within HP tuners, than the tuning package itself. Prior to my LS4/F40 swap, I had never used HP tuners or tuned an OBD2 car (just OBD1). I am not an electrical or computer person, my forte is on the mechanical side, so if I can learn it, many others can as well.[This message has been edited by fieroguru (edited 04-17-2016).]

|

|

|

E.Furgal

|

APR 18, 04:23 AM

|

|

| quote | Originally posted by fieroguru:

However, smoothing the valve covers isn't that simple... when you grind down the stands, you are left with holes in the valve cover that need to be welded up. Welding aluminum is not in the skill set of most DIY, so that isn't the direction for this swap. Simple, relatively inexpensive, and repeatable by others.

This swap will use the E40 ecm from the (05-06 LS4s). This ecm is quite fast and advanced, but it still uses a traditional VE table for tuning and isn't as reliant on the BCM.

The E67 (07+) ecm on my first swap was developed to enable VVT and GM switched from using a VE table to a series of coefficient equations. This used to make it tougher to tune VE, so many just ran MAF only. Now HP Tuners has virtual VE tables that make it easier to tune. The E67 is still much more reliant on the BCM for the brake position switch (case learn, cruise control, etc), which can complicate the swap.

I am not much of a fan with the aftermarket ecms. No aftermarket company puts in the same level of R&D and reliability testing as GM does with their ECMs.

I found the learning curve to be a bit steeper to understand and learn how to edit the scanner program within HP tuners, than the tuning package itself. Prior to my LS4/F40 swap, I had never used HP tuners or tuned an OBD2 car (just OBD1). I am not an electrical or computer person, my forte is on the mechanical side, so if I can learn it, many others can as well.

|

|

|

|

|

fieroguru

|

JUN 25, 09:31 PM

|

|

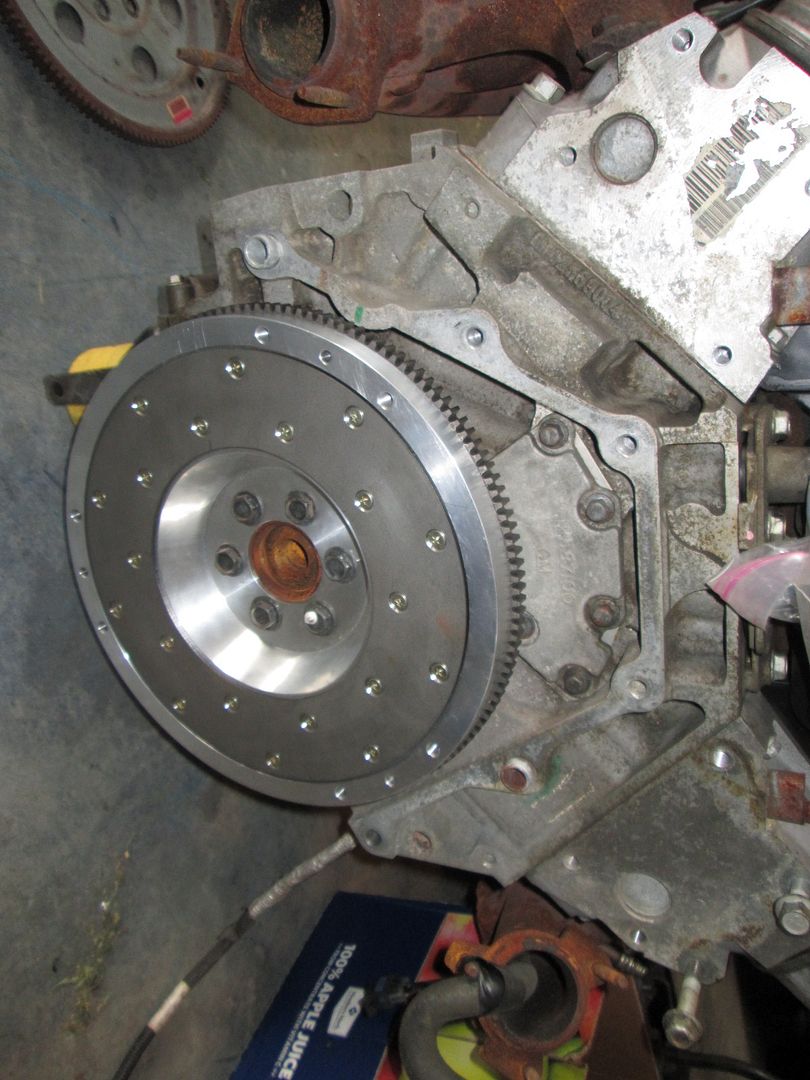

Today I put the first test run flywheel from the machine shop together (been sitting in a box in storage or on the shelf for nearly 2 years). Once I am done verifying all the dimensions, I will be ready to order the first production batch of 5.

I also milled another starter bracket from a print I had created (again 2+ years ago) to confirm the dimensions are correct. I still have to make and print the mounting ears, and weld it up. Once the starter bracket is done and the transmission clearance work complete, I will mate the engine/transmission and flywheel to verify everything works as it should (and do a compression check on the LS4 engine). Then I will pull the starter bracket back off to make an assembly fixture. While sending the prints for the starter bracket and mounting tabs out for quoting from the machine shop.

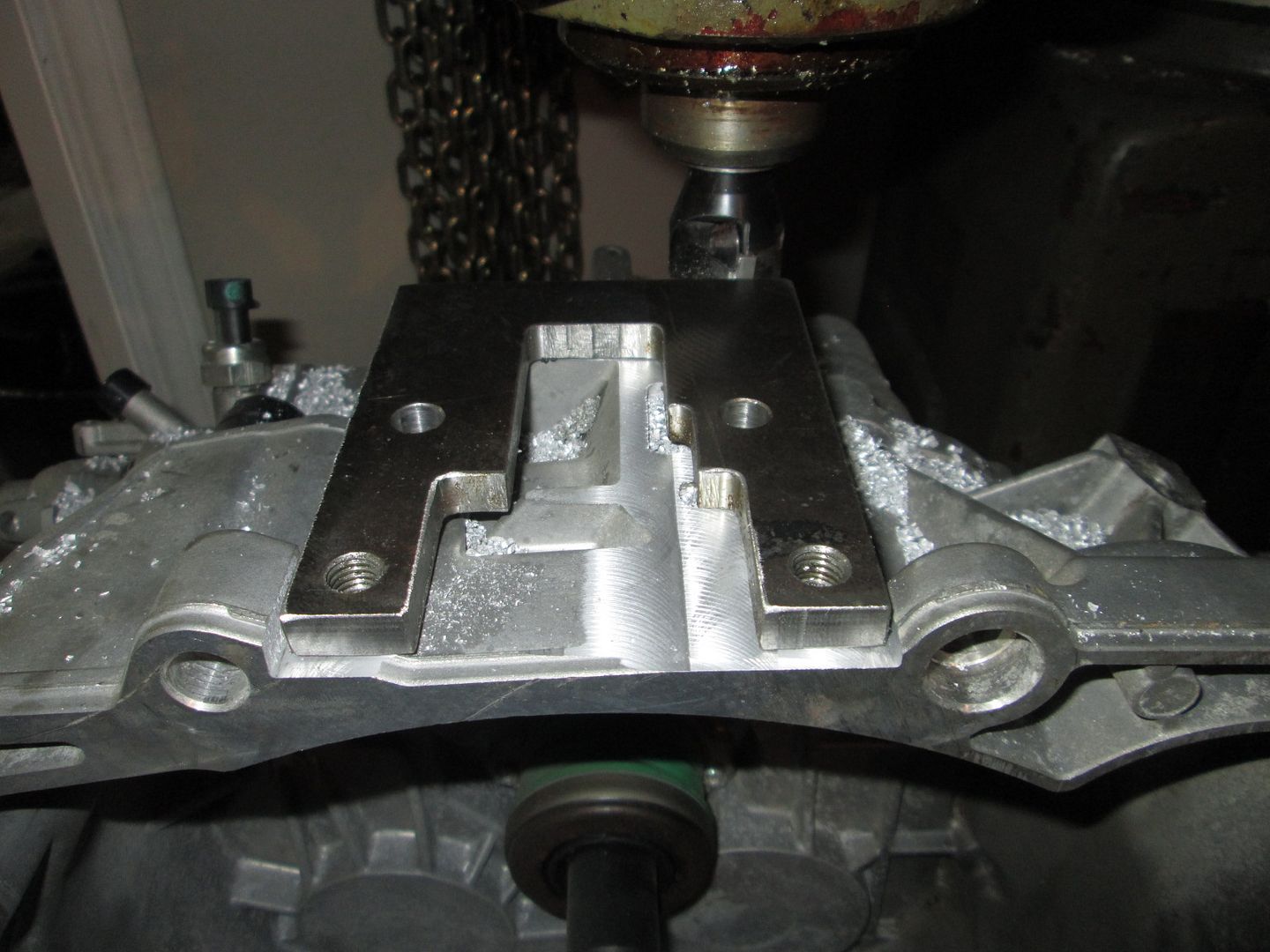

Here is the starter mounting plate and the transmission mounted in the mill for clearance work. All that is left on the transmission clearancing is the notch through the case for the starter gear. I will mill it once I have the starter mount bolted to the transmission.

[This message has been edited by fieroguru (edited 06-25-2016).]

|

|

|

motoracer838

|

JUN 26, 11:49 AM

|

|

|

|

KissMySSFiero

|

JUN 26, 11:55 AM

|

|

I'm glad to see you're back on this one.

Is the LS4/F40 going to take priority over the LS4/4t65e?

Any chance you'll offer the starter pad with mounting ears only for those using a getrag w/ HTOB?

I just picked up a billet LS4 flywheel cheap because they were manufactured wrong. The pressure plate bolt holes were off.

Tough to pass on at the price. They have 3 left.

http://www.ebay.com/itm/361...e=STRK%3AMEBIDX%3AIT------------------

SSFiero@Aol.com

|

|

|

fieroguru

|

JUN 26, 06:16 PM

|

|

| quote | Originally posted by motoracer838:

Guru, you have a PM.

Joe |

|

Answered.

| quote | Originally posted by KissMySSFiero:

Is the LS4/F40 going to take priority over the LS4/4t65e?

Any chance you'll offer the starter pad with mounting ears only for those using a getrag w/ HTOB?

|

|

Since I don't have a fiero to install either the LS4/F40 or LS4/4T65E-HD (gave my 4cyl 88 GT clone to my nephew), I will likely bounce back and forth between them making the various parts. However, people have waited long enough for the LS4/F40 flywheel and starter mount, so they are at the top of the R&D list.

Yes the starter bracket will be available individually and you would need it unassembled for your project.[This message has been edited by fieroguru (edited 06-26-2016).]

|

|

|

fieroguru

|

JUN 26, 06:43 PM

|

|

It was 92 degrees in the garage today... but I finished all the machine work on the F40 and welding up the starter bracket. So I pulled the engine out from under the sheet metal brake, installed the flywheel, and bolted up the transmission w/ starter.

Pulled the plugs, squirted some oil in the cylinders, hooked up the jump box, and turned the switch...

|

|

|

motoracer838

|

JUN 26, 11:34 PM

|

|

Guru, thanks for the quick response, the info is a big help. I'll probably need an unassembled starter bracket as well. don't expect to need it before late fall/ early winter.

Joe

|

|

|

FOREVER88

|

JUN 29, 12:54 AM

|

|

Good to see progress hear once more. Please add me to your list of customers for a flywheel and starter mount.

Regards

Glen

|

|

|

CTFieroGT87

|

JUN 29, 09:39 AM

|

|

|

Eagerly awaiting the LS4/F40 build kit......give me the chance to spend money!

|

|

|

|