|

| World's slowest Fiero/Quad 4 Swap (Page 39/51) |

|

Quadfather

|

SEP 05, 08:43 PM

|

|

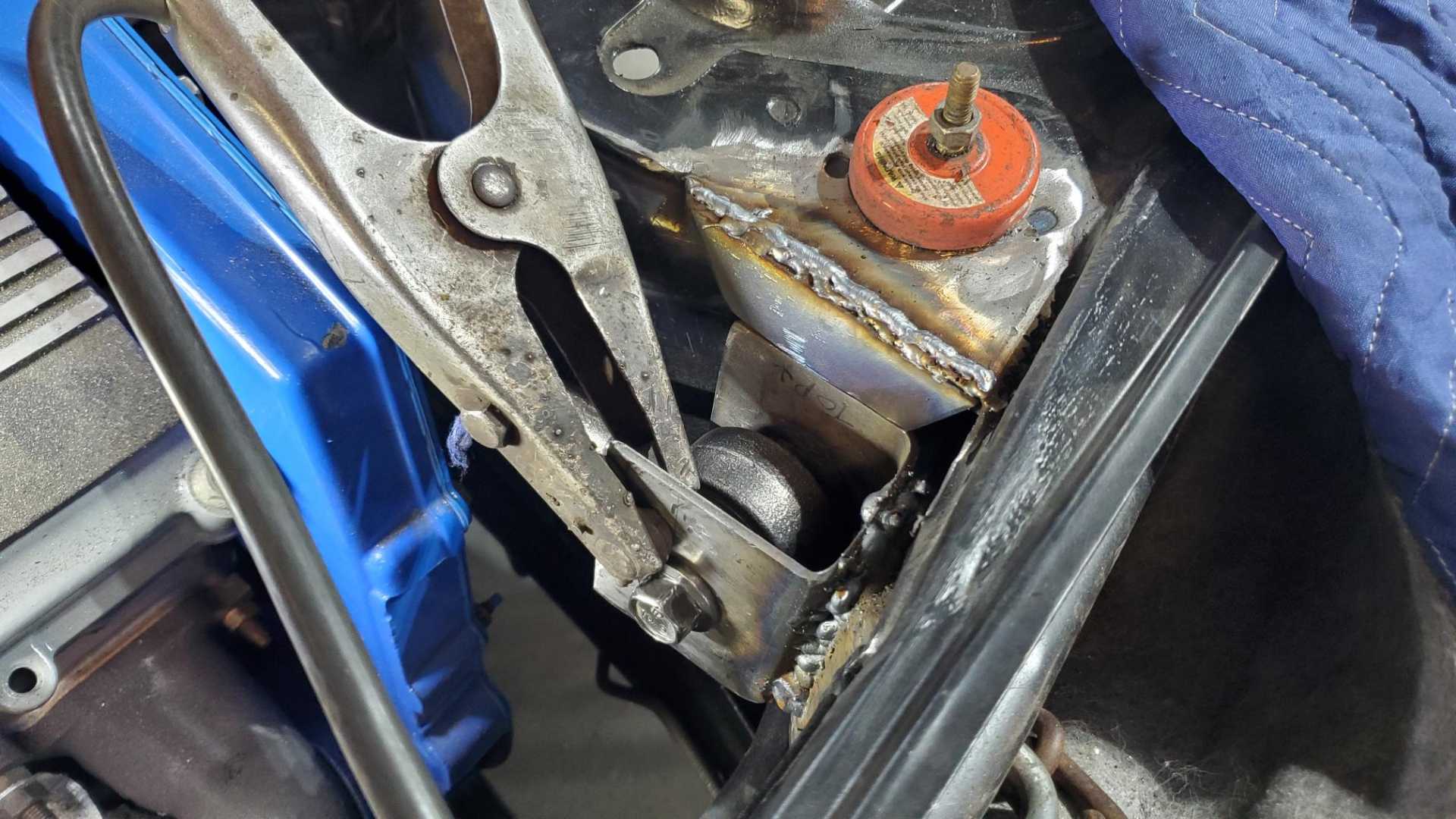

The holder for the strut ended up being four pieces: the curved piece welded back into the top of the strut mount, the three-sided bracket for the eye, a piece for the bottom of the bracket to give it strength, then a flat piece to weld from the curved piece to the bracket.

Here's the plate that mounts to the engine.

|

|

|

Quadfather

|

SEP 05, 08:50 PM

|

|

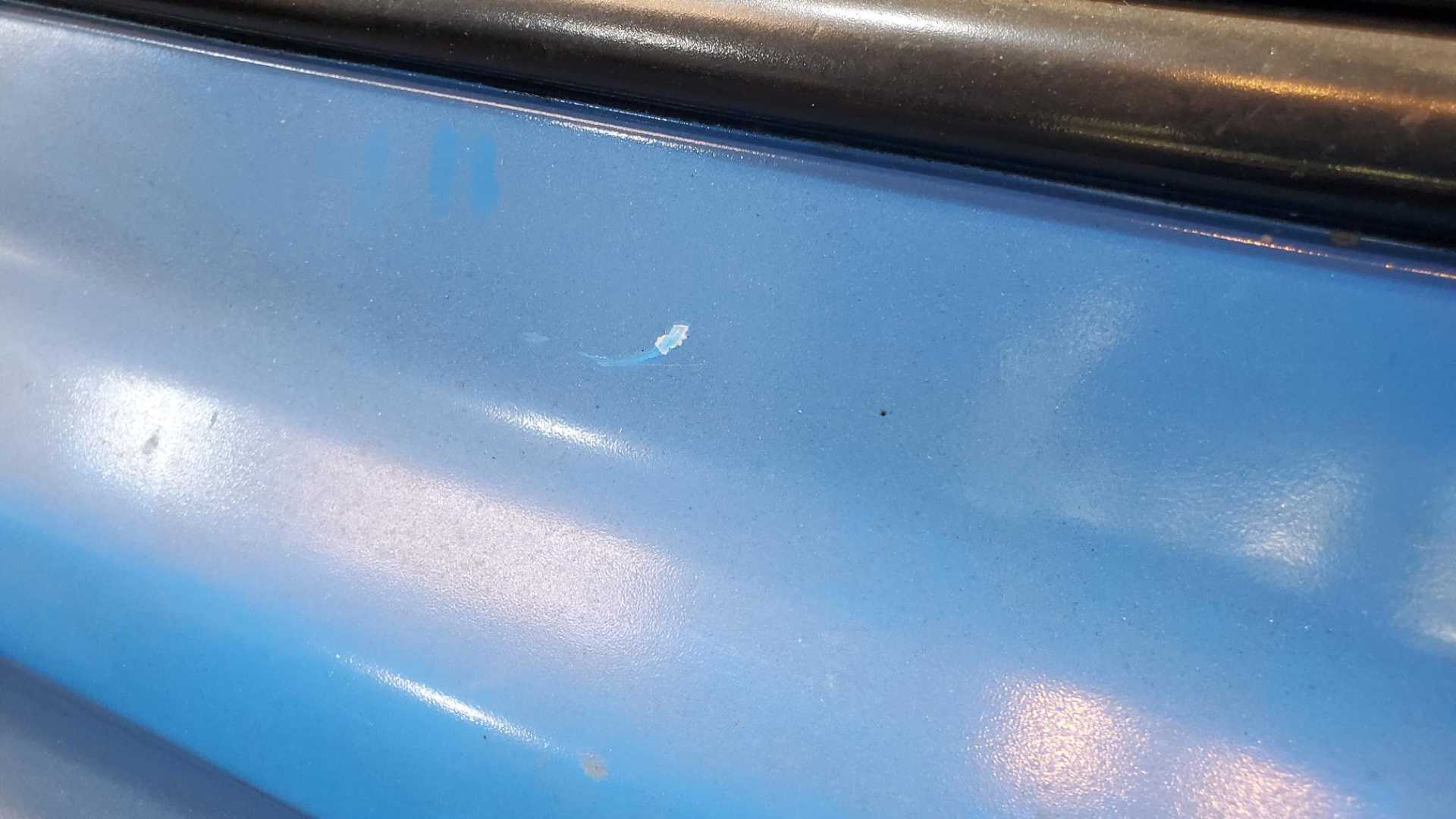

I was feeling pretty good about things until I started lifting the car up to take the engine and cradle out. I wasn't paying attention and the prop rod fell forward and put a big scratch on the rear fascia.

Wish I'd gotten the swap finished and the engine running, THEN done paint and body. On the other hand, this is one of the reasons I picked Rust-Oleum instead of regular automotive paint.[This message has been edited by Quadfather (edited 10-07-2022).]

|

|

|

zkhennings

|

SEP 13, 02:16 PM

|

|

|

Looking good! Is your welder running full duty right now? It looks like if you turned the heat up a little it would help get a little better penetration. I think your new torque strut is going to work great!

|

|

|

Quadfather

|

SEP 15, 10:08 AM

|

|

| quote | Originally posted by zkhennings:

Looking good! Is your welder running full duty right now? It looks like if you turned the heat up a little it would help get a little better penetration. |

|

Sometimes I have trouble with the panendermic semi-boloid slots of the stator. This is a known fault with these welders, because every seventh conductor is connected by a non-reversible tremie pipe to the differential girdle spring on the “up” end of the grammeters.

|

|

|

Quadfather

|

SEP 15, 08:05 PM

|

|

After refereeing a soccer game this evening I was surprised to see what was parked behind my truck.

So nice to see a piece of American iron in the middle of all the minivans and crossovers.[This message has been edited by Quadfather (edited 09-16-2022).]

|

|

|

zkhennings

|

SEP 19, 11:35 AM

|

|

| quote | Originally posted by Quadfather:

Sometimes I have trouble with the panendermic semi-boloid slots of the stator. This is a known fault with these welders, because every seventh conductor is connected by a non-reversible tremie pipe to the differential girdle spring on the “up” end of the grammeters.

|

|

Lol classic.

I just see this behavior on my own welder if I am welding on 120 vs 240, on 120 the welds like to sit on top more. Was mostly curious what machine you are running.

|

|

|

Quadfather

|

SEP 21, 08:38 AM

|

|

I use the little Lincoln MIG welder my dad bought 30+ years ago. It’s very user friendly. When my welds look poor it’s usually because I’ve failed to prepare the metal, failed to set up the welder or even forgotten to turn off the fan.

This welder is 110v. It would be nice to have it on a dedicated circuit, but as long as I’m not using a lot of juice for other things simultaneously it seems to do fine.

[This message has been edited by Quadfather (edited 09-21-2022).]

|

|

|

Quadfather

|

SEP 21, 08:52 AM

|

|

I haven’t done any work on the car for the last week because I focused on another air compressor project. Last November our gas water heater quit working. The problem was with the electronics, not the tank itself. I’d heard about people using water tanks as air compressor tanks so I did some research. They’re factory tested to 300 psi, but I watched some YouTube videos on how to use water and a pressure washer to test one myself. I tested this one to about 275 psi so it’s fine for an air compressor.

The 20-gallon tank in the compressor I had in my own garage had started leaking. Like the welder, it was one my dad bought after a house fire in 1989. Finally got tired of working around the water tank in the shop. Pretty straightforward to mount the pump and motor on the water tank, with less than $40 in fittings and tubing. It’s amazing how quiet it is. Not sure if it’s 40 or 50 gallons. Just about finished, so I’m ready to get back to work on the car.

|

|

|

zkhennings

|

SEP 23, 01:58 PM

|

|

Wow that's a really cool idea!

I like those old Lincolns, my friend has a very similar one and it is a great machine. I was not trying to make any kind of negative comment about your welds, I have just been rebuilding a bus and have been doing such a ridiculous amount of welding compared to ever before, did a bunch of it on 120, got sick of that and made an adapter for the drier plug at my apartment to weld on 240, and have been doing a lot of experimenting in general. I am no expert by any means, just a curious hobbyist, sorry if I offended. I think your build is coming along very nicely and it is one of the few I check in on regularly for updates!

|

|

|

Quadfather

|

SEP 23, 02:36 PM

|

|

Whoa, a BUS? Now THAT'S a project. I'll have to read your thread more carefully when I have some time this weekend.

No worries about your comments, I wasn't offended. As an amateur welder, I appreciate the feedback. Most of my welds look pretty good, some look rough and some come out so perfect I want to show the world. The ones that look really bad get cut apart and redone. I've found the biggest cause of inconsistency is haste, usually when I'm nearing the end of my allotted shop time for the day and want to feel the rush of having welded something.

Now that the compressor tangent is done, I'll be working on the car this weekend. Next step is to pull the engine and transmission off the cradle, cut off the unneeded torque mount, repaint then re-attach the engine/transmission. After THAT, it's engine wiring harness time.

|

|

|