|

| World's slowest Fiero/Quad 4 Swap (Page 38/51) |

|

Wichita

|

AUG 18, 09:51 AM

|

|

|

|

Will

|

AUG 18, 03:31 PM

|

|

Driveline torque is applied at the AXLES, so the farther from the axle centerline the torque strut is, the more effective it is.

That's why the factory dogbone is mounted on TOP of the engine rather than to the cradle.

|

|

|

Quadfather

|

AUG 18, 04:45 PM

|

|

Well, I’d argue that the dog bone was put where it was on the Fiero because that was the easiest, and therefore cheapest, place to put it. Putting it on the cradle, especially the ‘84-‘87, would’ve required some engineering. It’s the same reason the Fiero ended up with a barely modified X-body cradle in the first place.

Anyway, I like fabricating stuff like this so I’ll experiment with a dog bone that bolts to the lift plate on the end of the engine.

|

|

|

Quadfather

|

AUG 21, 08:08 AM

|

|

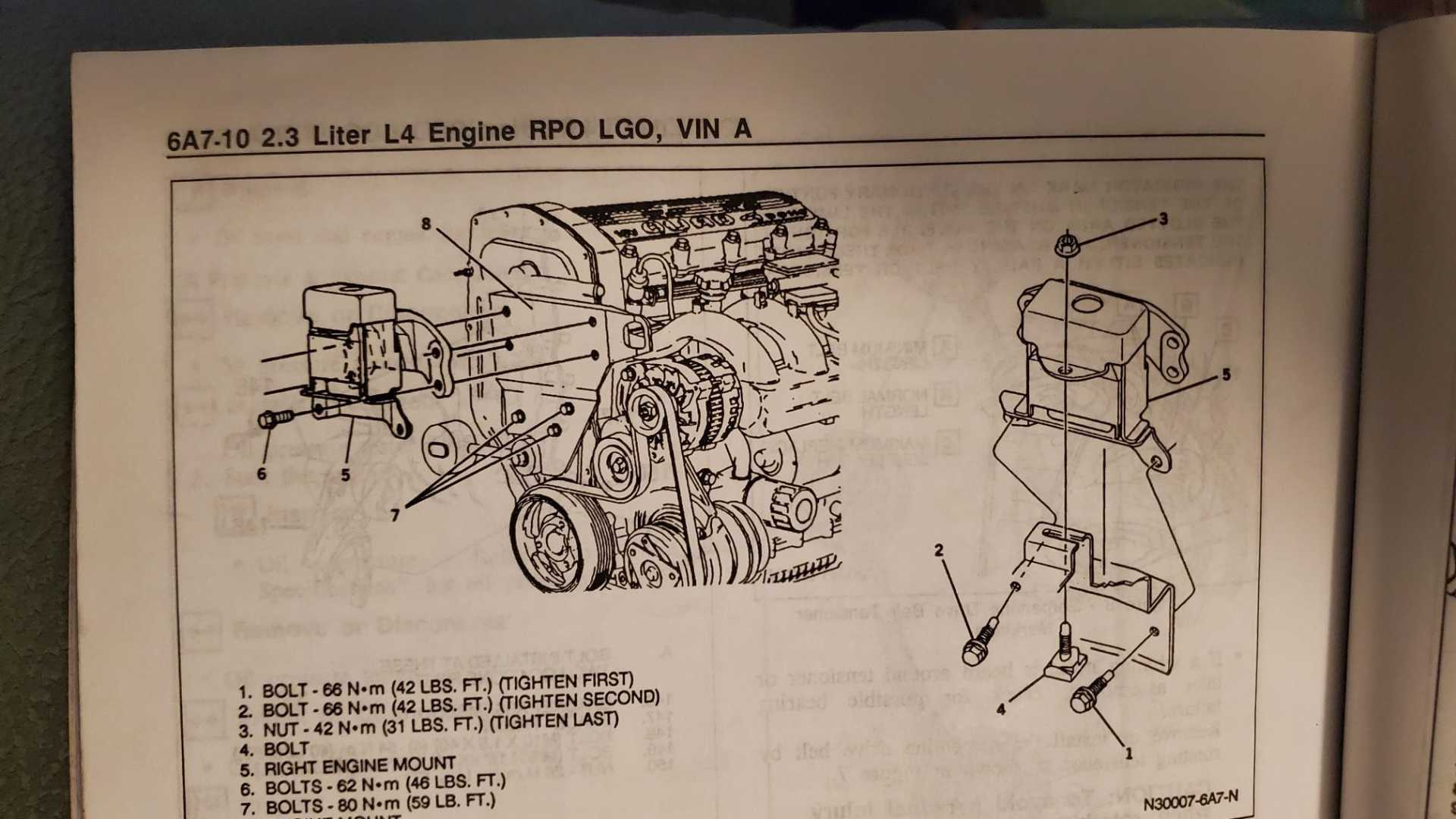

I can’t remember why I decided that the torque mount HAD to be attached to the cradle, but I set that notion aside and started thinking about just doing it the best way. So why not adapt the torque mount from the Beretta? Hmmmm.

Here’s what it looked like in my GTZ.

Half of the mount bolted to the fender/fender well. Hopefully I saved that half of the mount and it’s sitting in the shop somewhere. I do have the engine half.

To make this work I’d have to fabricate a plate that attaches to the strut tower. I got to thinking about this while doing a little side project, cleaning and painting the engine compartment.[This message has been edited by Quadfather (edited 08-21-2022).]

|

|

|

Quadfather

|

AUG 21, 08:21 AM

|

|

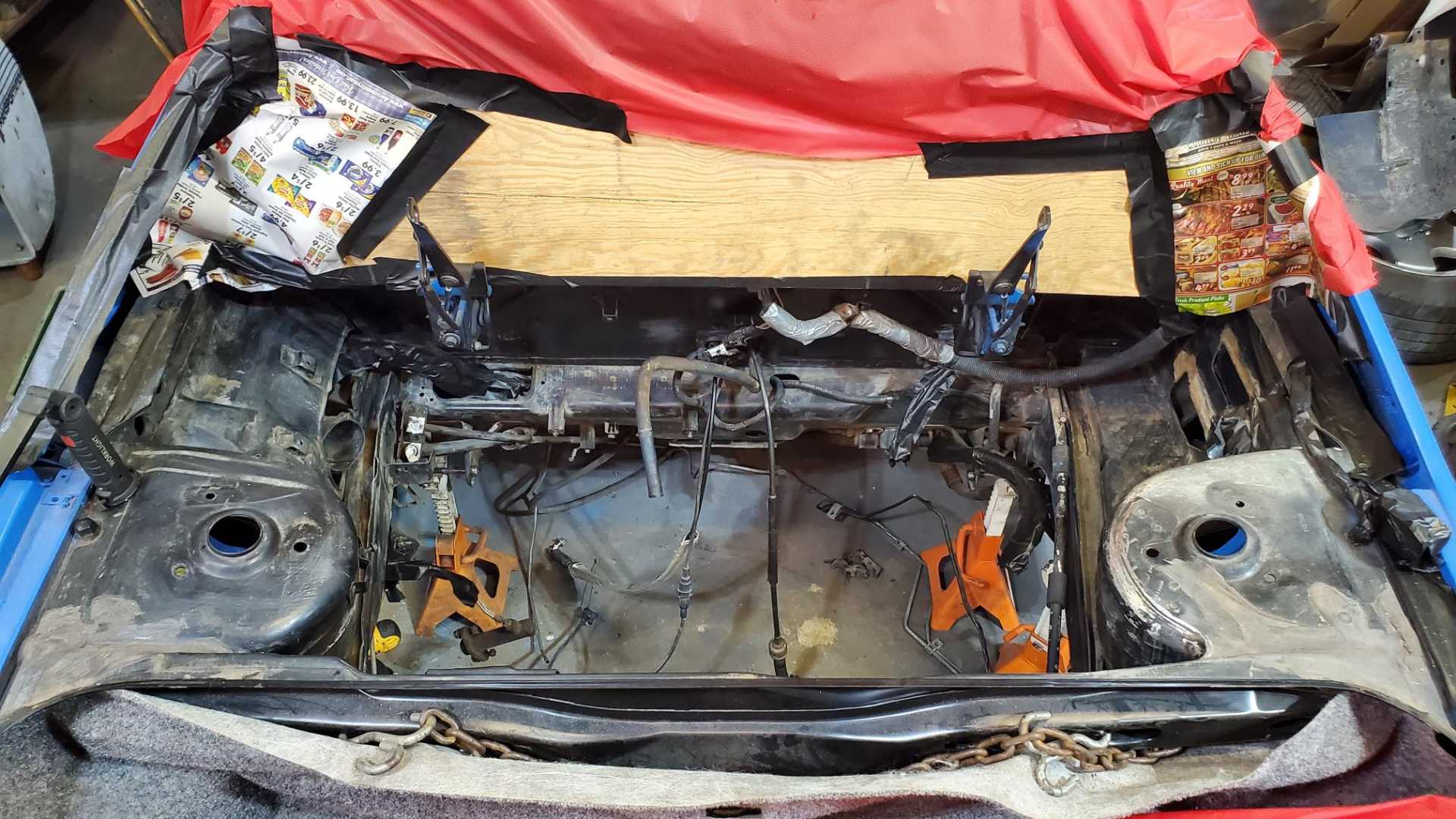

About that side project.

I used an angle grinder and a die grinder to cut out and clean up the factory torque mount.

The worst part of the process was crawling in and out.

|

|

|

Quadfather

|

AUG 21, 08:34 AM

|

|

As I mentioned, my wife and I spent a week in Pennsylvania. We did a day trip to the Battleship New Jersey, which was excellent, but we also did a little side trip.

The John F. Kennedy, CV-67, is docked at the Philadelphia Navy Yard. Only a couple small Navy operations are still using the Yard, and the rest is being redeveloped. The Kennedy is docked there as it waits to be scrapped, so I figured we’d be able to drive right up to it.

It was decommissioned in 2007 after 38 years of service. Sat here for 10 years while the Navy waited for someone to step forward and turn it into a museum. When that didn’t happen, it was sold for scrap for $1.

|

|

|

Will

|

AUG 29, 09:07 PM

|

|

| quote | Originally posted by Quadfather:

Well, I’d argue that the dog bone was put where it was on the Fiero because that was the easiest, and therefore cheapest, place to put it. Putting it on the cradle, especially the ‘84-‘87, would’ve required some engineering. It’s the same reason the Fiero ended up with a barely modified X-body cradle in the first place.

Anyway, I like fabricating stuff like this so I’ll experiment with a dog bone that bolts to the lift plate on the end of the engine. |

|

It was put where it was because it was a best combo of the best location and relatively easy to put there.

Any mounting of the dogbone to the cradle would reduce the perpendicular distance from the dogbone's "line of action" to the axle centerline. Reducing that distance increases the load on the dogbone and mounts. That's why GM put it as far away from the axle as they reasonably could.

You'll see the same thing on FWD cars. Dogbone(s) going from the top of the engine to the radiator header panel.

Don't you think GM would like to skip the extra main-line step of bolting those dogbones in place? Why would they include that step in the main line if it weren't necessary for the dogbones to go there?

|

|

|

Quadfather

|

SEP 05, 08:16 PM

|

|

Saw a cool car at the parts store. This a TR8, but I remember when commercials for the Triumph TR7 were all over TV in the late 70s.

The tag line was always, "The shape of things to come." They sure got that right.[This message has been edited by Quadfather (edited 09-05-2022).]

|

|

|

Quadfather

|

SEP 05, 08:25 PM

|

|

Back to the torque strut mount. I spent a lot of time looking at the engine and the engine bay and finally decided to go back to the original plan I had for mounting the torque strut. I used the mounting plate/lifting eye on the end of the Quad by fabricating a bracket that uses the same four holes with captured nuts, welded to a modified tie rod end housing.

I used the eye from the Ford anti-sway bar link I got from the salvage, welded to the threaded end of the same tie rod.

First up was rebuilding the factory mounting point on the Fiero.

I took my time welding around the new piece of sheet metal but still got some warpage. It made for some rough looking welds, but they ground down just fine.

|

|

|

Quadfather

|

SEP 05, 08:35 PM

|

|

I bought a piece of sheet metal from Lowe's to speed up the process. Hunting around in my stash and then modifying whatever I could find was just going to take too long.

That allowed me to quickly fabricate the bracket to hold the sway bar link eye and I welded the big nut that came with the link to the bracket.

[This message has been edited by Quadfather (edited 09-06-2022).]

|

|

|

|