|

| World's slowest Fiero/Quad 4 Swap (Page 37/51) |

|

Will

|

JUL 26, 07:45 PM

|

|

|

Were you trying to save money by not buying Rodney Dickman or WCF transmission mounts/brackets?

|

|

|

Quadfather

|

JUL 27, 01:57 PM

|

|

| quote | Originally posted by Will:

Were you trying to save money by not buying Rodney Dickman or WCF transmission mounts/brackets? |

|

I've bought some parts from Rodney over the years and they've been great. WCF, on the other hand, doesn't have a very good reputation, in my opinion.

I am trying to save money wherever I can, but this is also the part of the project I like the most. Fabricating mounts is fun.

EDIT: With all due respect, if someone needs to buy mounts in order to move his project along, great. But this is one part of the project that helps make this car mine.[This message has been edited by Quadfather (edited 08-16-2022).]

|

|

|

Quadfather

|

JUL 28, 08:46 PM

|

|

|

|

Quadfather

|

JUL 28, 09:05 PM

|

|

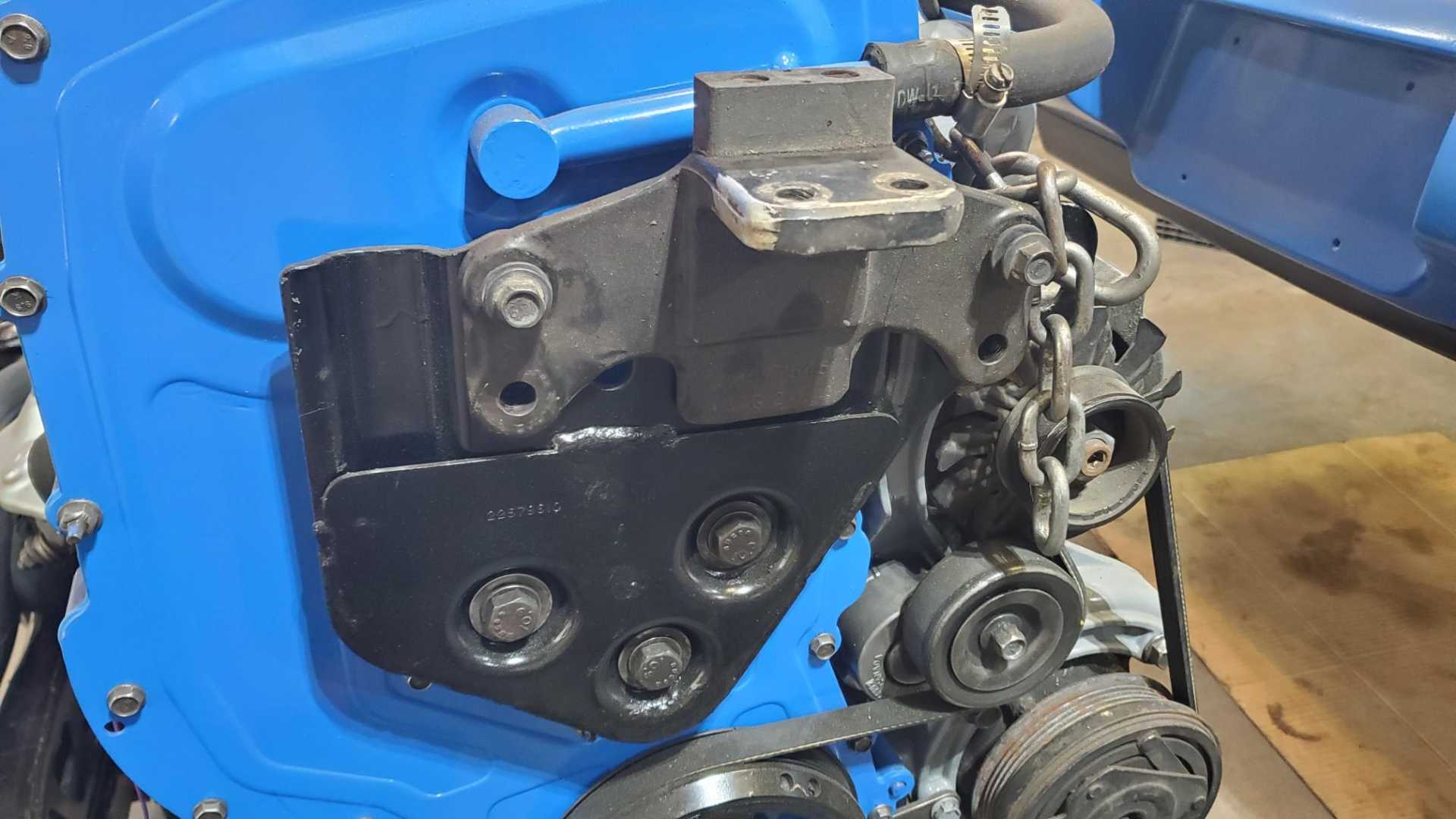

Next up is figuring out how to replace the dog bone. When I first set a Quad in the cradle and put it in the car, I fabbed up an adjustable mount using one end of an aftermarket dog bone with a big nut welded in the tube and a tie rod end threaded into the nut. I welded a flange on the other end to attach to the big fender mount that the GTZ used.

Other swappers cut up the stock dog bone mount on the front of the trunk. I tried that but made a hash of it and have always wanted to do something different.

I looked at a bunch of different swaps to see what other people have done. I liked Lunatic’s approach with the Ecotec, which was a long bar attached from the engine to the cradle, not the body.

The front of the engine is very close to lining up with the custom tie rod mount I welded to the cradle. I can use the same C channel to mount some kind of bushing, attached to a bent rod or pipe, with another bushing attached to the engine. Where to find something like that?

My favorite salvage didn’t disappoint. After 20 minutes of walking, in 107-degree heat, I found a 2008 Super Duty Ford pickup with the precise parts I needed. Someone was kind enough to have already removed the entire front clip and engine, giving easy access to the front anti-sway bar links. They’re cast iron so they’re weldable.

Found a section of pipe in my stash left over from a shopping cart, and it’s almost perfect.

Leaving for vacation tomorrow so no progress for a couple of weeks.

|

|

|

Quadfather

|

AUG 15, 01:31 PM

|

|

|

|

Quadfather

|

AUG 15, 01:38 PM

|

|

|

|

Quadfather

|

AUG 15, 01:44 PM

|

|

In order to finish welding the bracket to the cradle I'll have to lift the engine off and turn the cradle on its side. Then I'll sand and paint and reinstall everything.

While waiting for the welds to cool down I made progress on cleaning up the engine bay. We're due for a big cool down this week so I'm hoping to make significant progress over the coming days and weeks. We'll see.

|

|

|

zkhennings

|

AUG 16, 11:41 AM

|

|

Torque is applied at the wheels and through the axles to the trans, which then applies force to the respective engine and transmission mounts. The original dogbone is up so high so that it can counter this moment from a position of good mechanical advantage.

Your new mount is almost inline with where the torque is being applied to the engine/transmission assembly, and you may find that it does not do as much as you want and may bend the mounting brackets as a lot of force will be going through it due to the small moment arm. I think it is worth trying, but if you have issues with motor movement you may want to relocate to a more stock location, or make a really long motor mount with a mounting location at the extreme ends and not run a dogbone/torque mount at all. See ericjon262s build for a really good example, though he extended his mount both directions and you probably only need to extend it in one direction.

Great progress though, take advantage of the nice weather![This message has been edited by zkhennings (edited 08-16-2022).]

|

|

|

Quadfather

|

AUG 16, 08:15 PM

|

|

That’s a valid point. As I mentioned earlier in the thread, I had planned for years to attach the dog bone to the passenger side of the engine and modify the stock body dog bone mount to accept it. Then I saw Lunatic’s design for his Ecotec swap and really liked it.

This is his photo:

Now that I’ve cut out the stock body dog bone mount and seen how much space there is between the body and the passenger side of the engine, I may try something like Lunatic’s.

The cold front is moving through Oklahoma even as we speak and I have a day off tomorrow, so let’s see how inspired I feel when I get to the shop.[This message has been edited by Quadfather (edited 08-16-2022).]

|

|

|

zkhennings

|

AUG 17, 10:40 PM

|

|

|

That would give you a much better moment arm, but it will see a lot of force due to the angle, so make sure to make it beefy! I'd maybe recommend bolting it with multiple bolts to the motor and just using a bushing on the cradle mount side to remove a degree of freedom.

|

|

|