|

| World's slowest Fiero/Quad 4 Swap (Page 32/51) |

|

Quadfather

|

FEB 13, 07:32 PM

|

|

|

|

Quadfather

|

FEB 20, 09:00 PM

|

|

|

|

Quadfather

|

FEB 27, 10:29 AM

|

|

The replace clutch release fork arrived on Friday and it’s a perfect match. I ordered it from GMPartsGiant.com.

Unfortunately, that site doesn’t have the needle bearings anymore. A Tulsa bearing dealer can get them for me but I wanted to wait until the fork arrived to make sure it was the correct one.

[This message has been edited by Quadfather (edited 03-20-2022).]

|

|

|

Quadfather

|

MAR 19, 09:14 PM

|

|

|

|

Quadfather

|

MAR 19, 09:26 PM

|

|

Bolted on and torqued the flywheel, then aligned the clutch disk and bolted on the pressure plate, then bolted the transmission to the block.

While bolting the mounting brackets to the transmission, this happened:

I was pretty bummed, but after looking at the photo I think I can just drill the hole deeper and tap some more threads.

I also realized I forgot to torque the pressure plate bolts, so the transmission will have to come off tomorrow.

I epoxied the broken piece back on, then decided to fill in the hole and re-tap it.[This message has been edited by Quadfather (edited 03-27-2022).]

|

|

|

Quadfather

|

MAR 27, 07:05 PM

|

|

|

|

Quadfather

|

MAR 27, 07:18 PM

|

|

Still a lot of work to do. I never cleaned the throttle body after removing if from the GTZ 10 years ago. I also need to buy all new hoses, including vacuum and the preformed ones for the oil separator.

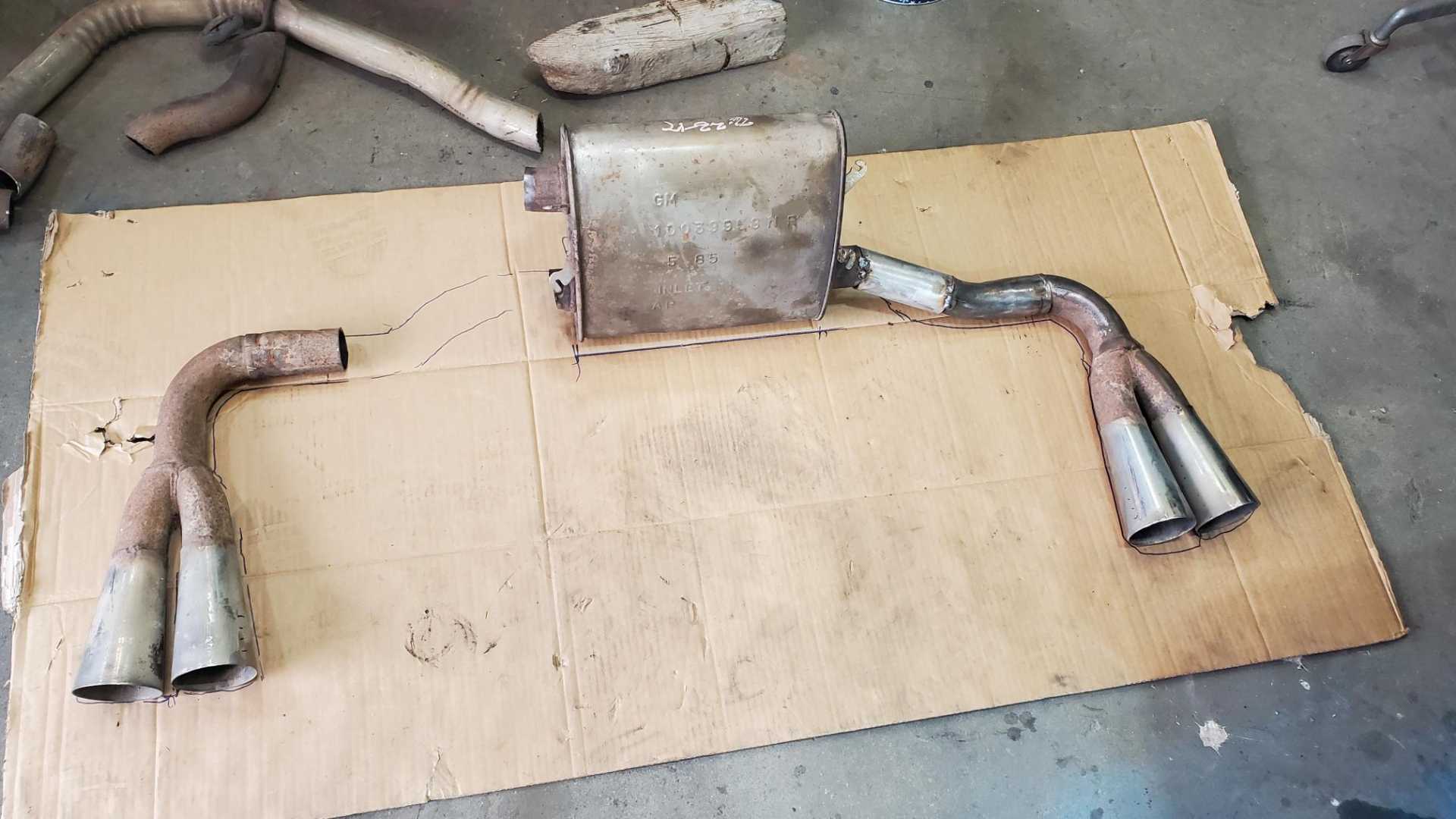

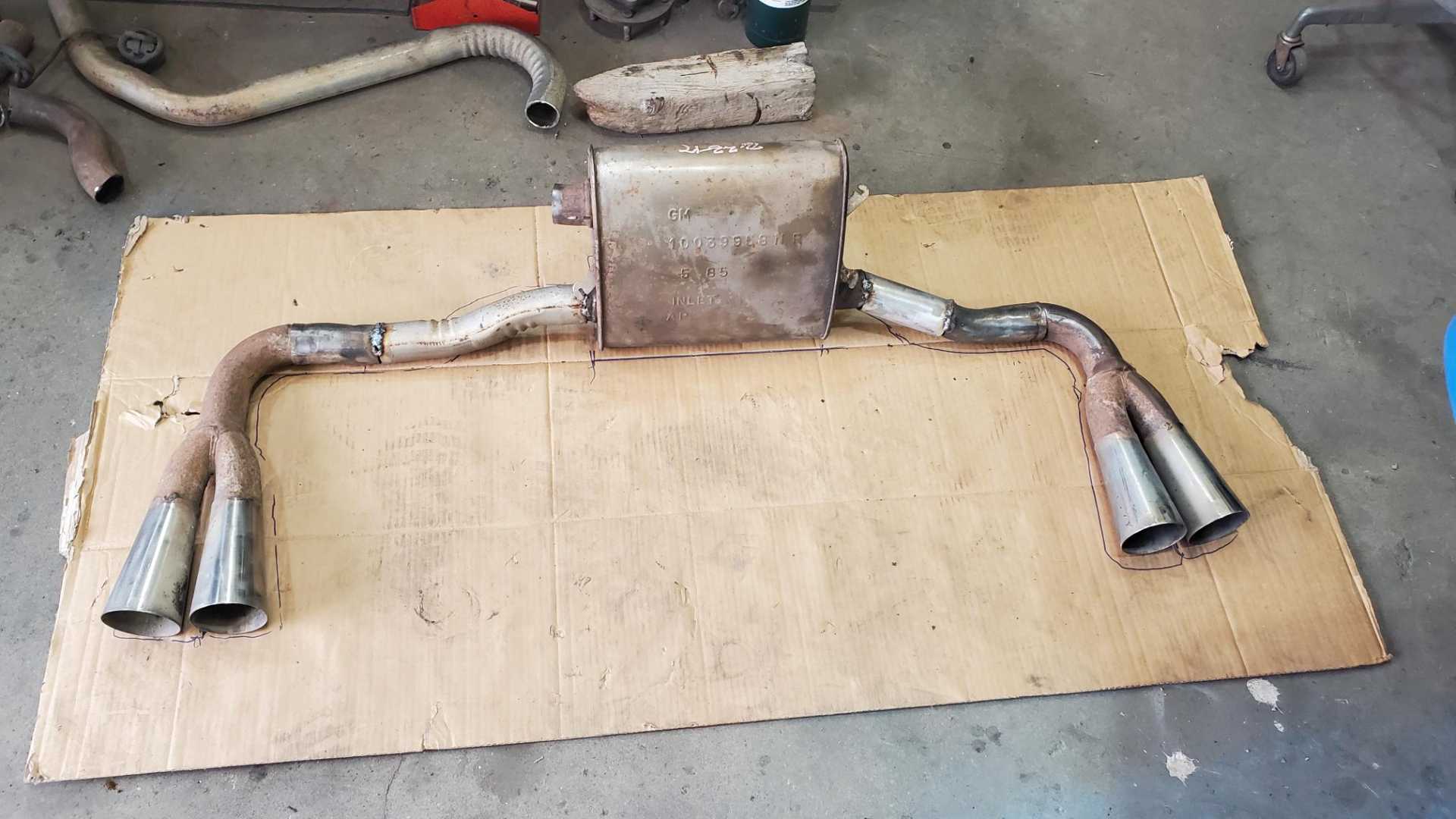

Also have to figure out the fuel lines, since the Quad’s are on the back of the engine. Years ago I bought a muffler from a V6 Fiero in the salvage, so I’ll have to fabricate the pipe to mate it to the Quad’s down pipe.

Of course, after getting all these items squared away, I won’t be able to avoid having to dig into the wiring harness.[This message has been edited by Quadfather (edited 03-27-2022).]

|

|

|

Quadfather

|

APR 10, 07:43 PM

|

|

Saw this on Facebook and it really hit home.

[This message has been edited by Quadfather (edited 04-10-2022).]

|

|

|

Quadfather

|

APR 10, 07:49 PM

|

|

|

|

Quadfather

|

APR 10, 07:59 PM

|

|

Then, back to the exhaust. Working on the exhaust system is, well, exhausting. After rolling around on the ground underneath the car it became apparent that the only way this V6 setup will work is by flipping the muffler 180 degrees.

I set the contraption on a piece of cardboard, traced it and checked the angle of the muffler, then started cutting.

I had a length of exhaust pipe whose origins I don’t remember and it was the perfect diameter and even had the precise bend I needed. The MIG welder forgives a lot of sins at a time like this.

It’s only temporary if it doesn’t work, according to Watch Wes Work on YouTube.

|

|

|