|

| LS4 / F40 Swap #2 - fieroguru (Page 21/21) |

|

KissMySSFiero

|

JUL 23, 09:11 PM

|

|

It’s been a few months for this.

Anything new on this one? ------------------

SSFiero@Aol.com

|

|

|

fieroguru

|

JUL 24, 12:03 AM

|

|

|

Nope... been living out of a suitcase for my day job for most of 2019. When I am home on weekends, most of my free time is spend processing orders for parts, doesn't leave much time for R&D projects.

|

|

|

fieroguru

|

SEP 02, 03:35 PM

|

|

Still living out of a suitcase for the day job, but had a rare weekend w/o a lot of orders to process.

Anyway.... around the 4th of July I picked up an 88 Fiero project so I would have a chassis for test fitting the LS4/F40 swap and finally lock down the engine/transmission placement and get working on finalizing the engine and transmission mounts...

We I actually had some time this holiday weekend to finish stripping the parts car, give it a bath in the driveway, and slide the LS4/F40 that has been on the bench for every under it.

I haven't started tweaking the placement, elevation or level yet, but at least it is in the chassis.

None of the removed sheet metal is needed for the LS4 swap, that is the way the chassis came to me.

|

|

|

fieroguru

|

NOV 24, 04:52 PM

|

|

A few weeks back I dialed in the placement of the drivetrain in the mock-up chassis, welded the drivetrain to the cradle, and pulled it back out and put it on the cradle fixture.

Today I fabricated the needed brackets to support the engine/transmission in the proper position so I can cut away the temporary mounts and make the final ones. Once I get these new drivetrain support brackets welded up, I will pull everything apart again.

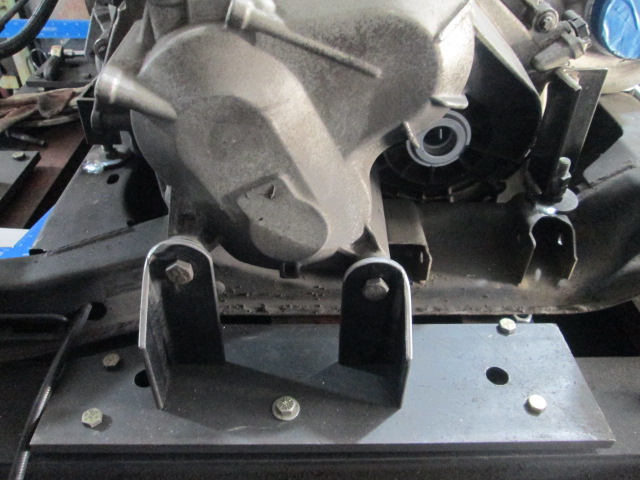

Here is the transmission side. There are 1/2" spacers between the vertical uprights and the F40. This will allow some slight adjustment side to side for use with other LS engines. In the far right, you can see the temporary adjustable mount used for mock-up. The lower portion is welded to the cradle.

Engine Side. This side the M16 bolt has a sleeve with a tapered end to keep it centered to the crankshaft. The sleeve can also slide in the vertical bracket. This will allow the same bracket to he used with the RWD LS engines. The F40 side will locate the drivetrain side to side, the engine side is just to keep things level and square to the cradle.

Once I get the support brackets welded, I am going to take everything apart to make room for LS4/F40 swap #1 on the cradle fixture. This means the LS4/F40 #2 will be on back burner status most of the winter, but some of the newer parts will be installed in the LS4/F40 #1 drivetrain.

|

|

|

Bob2112

|

NOV 25, 11:05 AM

|

|

|

Nice progress! Thanks for the updates.

|

|

|

fieroguru

|

NOV 28, 11:24 AM

|

|

The fixture brackets to locate and support the LS4/F40 above the cradle are now complete. All the temporary locating supports have been removed, so the drivetrain is just hovering above the cradle at this point. Now I can fabricate and weld on all the engine/transmission mounts for any Fiero cradle and the drivetrain will be properly positioned in the engine bay.

|

|

|

|