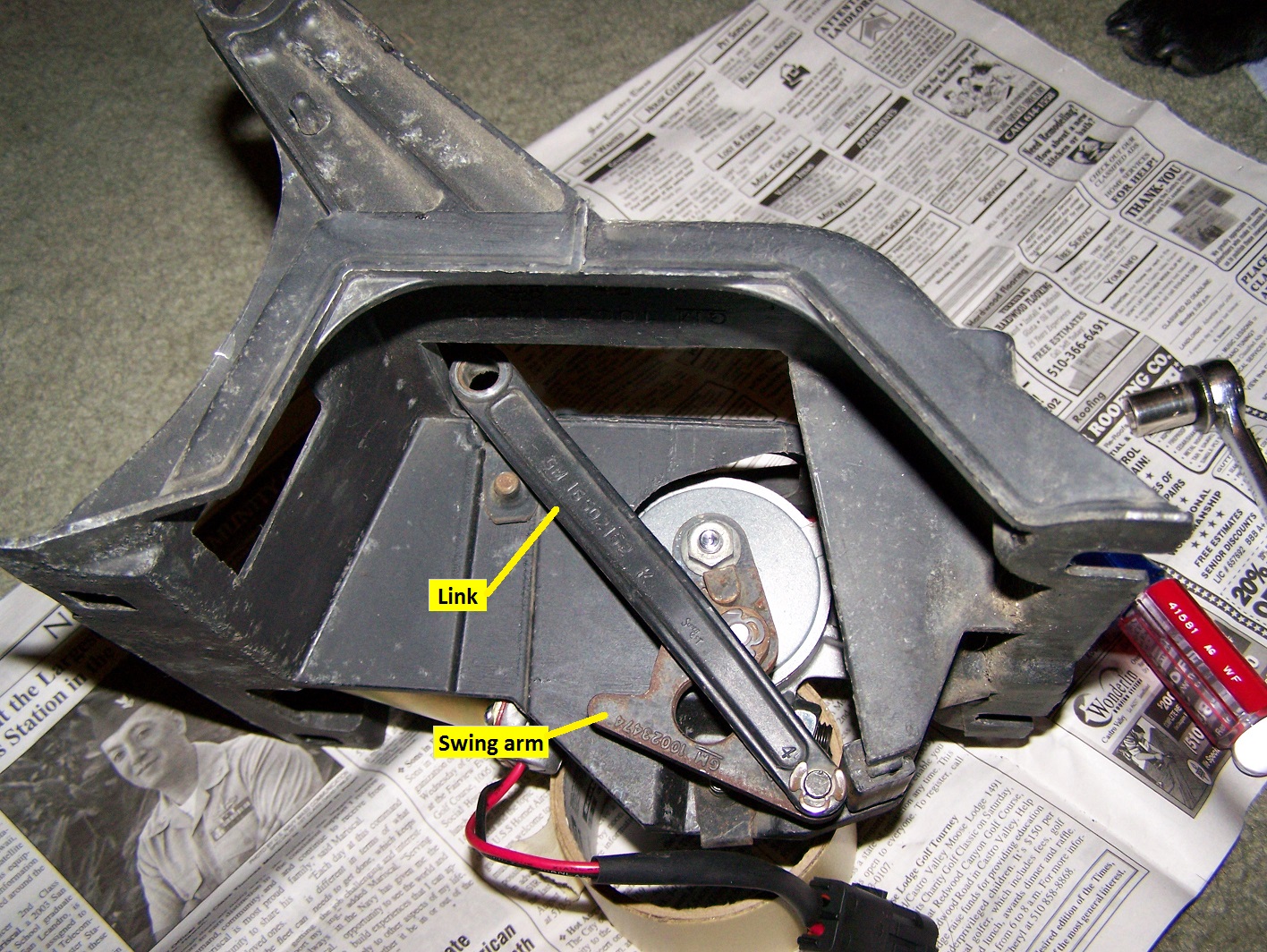

Lift mec have some play open/close the bucket. Only is tight at full open/close.

4 nuts holding lift on/in the car needs careful attention more then most think.

If you got lucky, you might see 1 set of "wear spots" where nuts were tighten at factory but many have been pulled 1 to many times and those wear spots mean nothing.

Buckets only hit the Door on 2 bearing strips...

|

| CLICK FOR FULL SIZE |

2 other spots in front is a backup and barely touches door.

Bucket Trim must not touch/rub the door anywhere else or extra load can bind or jam the system.

Many also let lift frame rest on top studs and HL bulb doesn't fully clear the hood at bottom of bulb.

See my Cave,

Headlights etc.

------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave