Once upon a time, I was an inexperienced Fiero owner... and I may have been a little overzealous with cleaning the middle intake manifold's mating surfaces with sandpaper / scotchbrite.

As I did not measure anything before/after, I don't know how much material I removed, or if I removed anything significant.

Apparently, sandpaper / scotchbrite may be too aggressive for cleaning these things, and can lead to flat surfaces becoming unflat.

I re-assembled the engine (with the thin cereal-box-like gaskets), and drove it like that for a few years, without noticing any problems... not that I would notice an intake sealing problem from the driver's seat.

Now, I have the engine apart (well, mostly buttonned up) for a rebuild, and I noticed that the bottom of the middle intake seems a little bit convex.

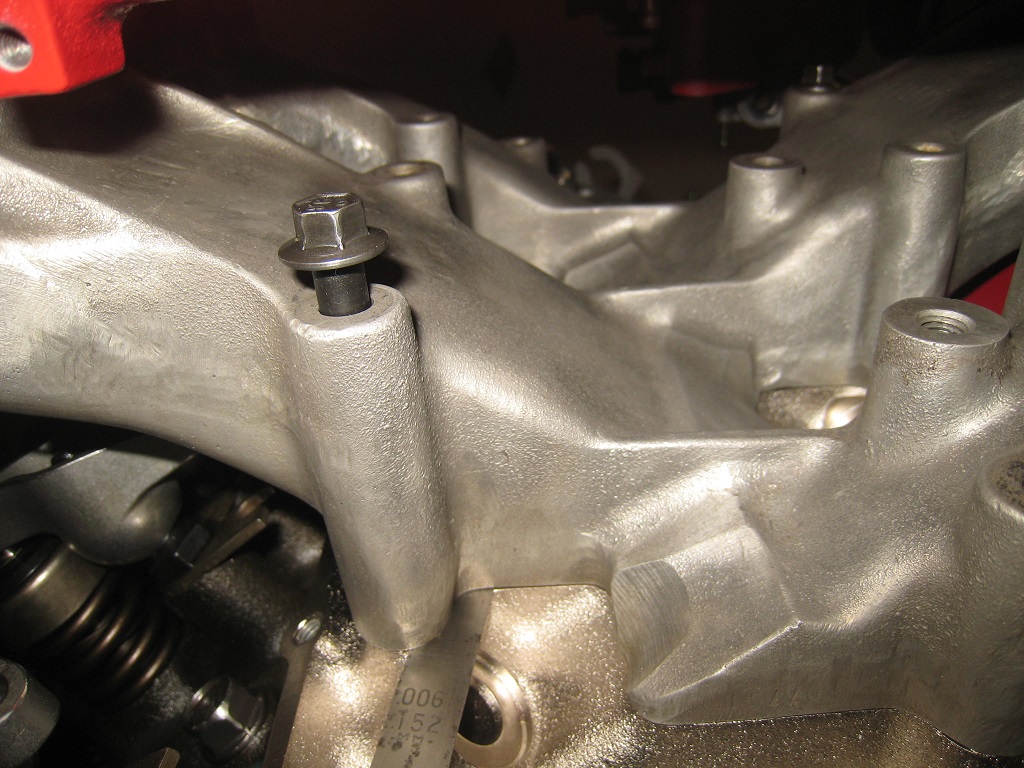

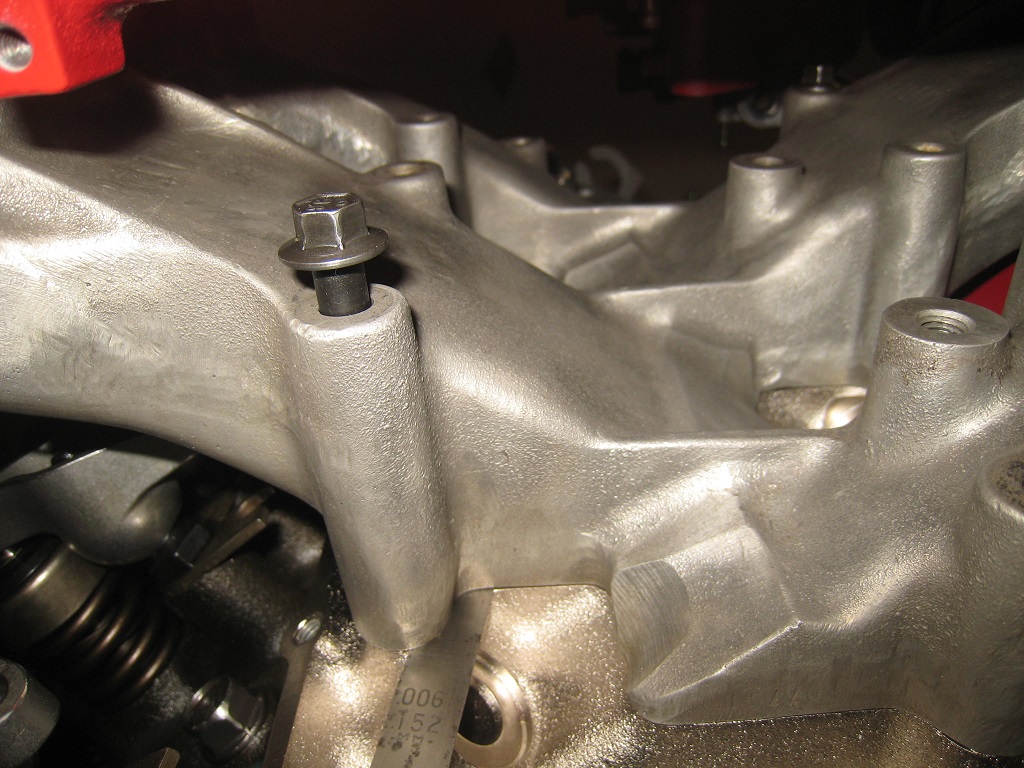

When I bolt down one corner of the manifold, there is a gap of 0.006" at the opposite end. Uh-oh, I said to myself.

I then found that tightening the bolt over the 0.006" gap allowed the gap to close. Good, the intake pieces are flexible enough to be forced together.

After tightening both ends, there are gaps in some places of 0.002".

Can the gasket handle this variation?

Ideally, I would not use RTV on the gasket, as I expect to have to pull the manifold for regularly for maintenance... so I don't want to deal with cleaning off RTV.

I could have the intake machined flatter by the machine shop that prepared my block, or I could look through my Fiero stash to see if I have an intake that hasn't had a retard go at it with scotchbrite.

What do y'all think about 0.002" gaps?

[This message has been edited by pmbrunelle (edited 01-01-2019).]