I'm going to post some pictures for the first time, here is my baby when I got it home back in February 2009. Car has 111,000 miles on it. Not in pristine shape but very presentable, all original body panels and interior (except for a goofy shift knob and grant steering wheel, both of which were replaced right away). Car ran good on the way home from Indy (3 hr trip) but pulled hard to the left when braking. Front brakes were seized.

Now for a little clean up

There were a few problems, the worst of which was that the transmission was grinding in 3rd gear. PO thought the clutch was not releasing, blah, blah blah, I figured it was the synchros and I was right. More about that later, first I had to get the transmission out. I did this the "hard way", hanging the engine and dropping the sub frame and transmission out the bottom.

Why would I do that? It's so much easier to drop the whole drivetrain right, maybe so, but engine work is for next winter, I didn't even want to tempt myself to tear into it.

Here is why I needed the cradle out....

Sans transmission

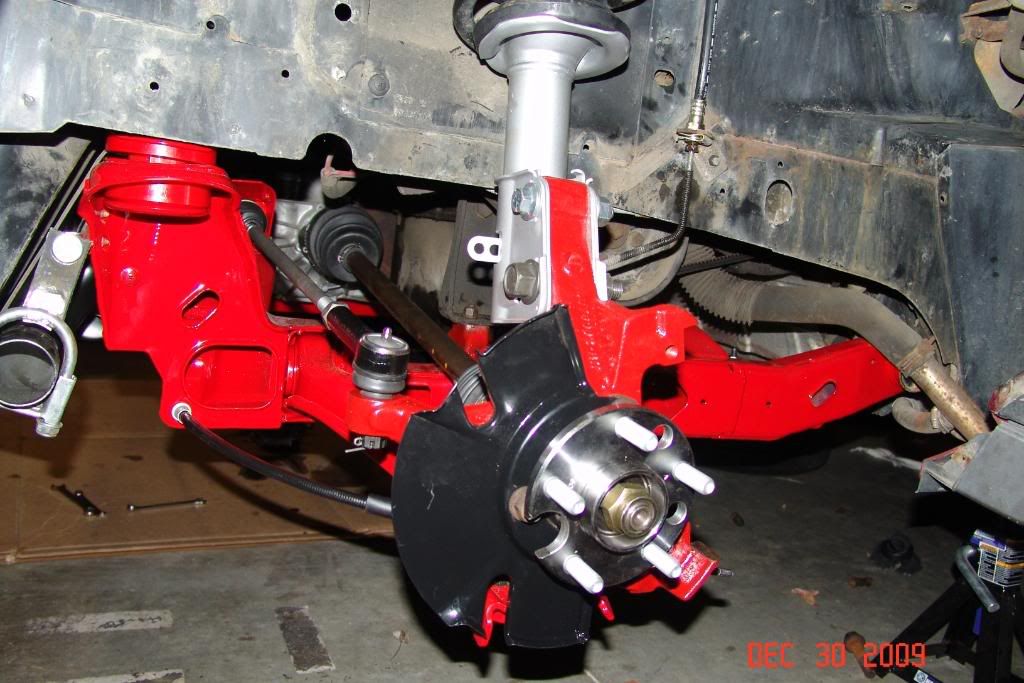

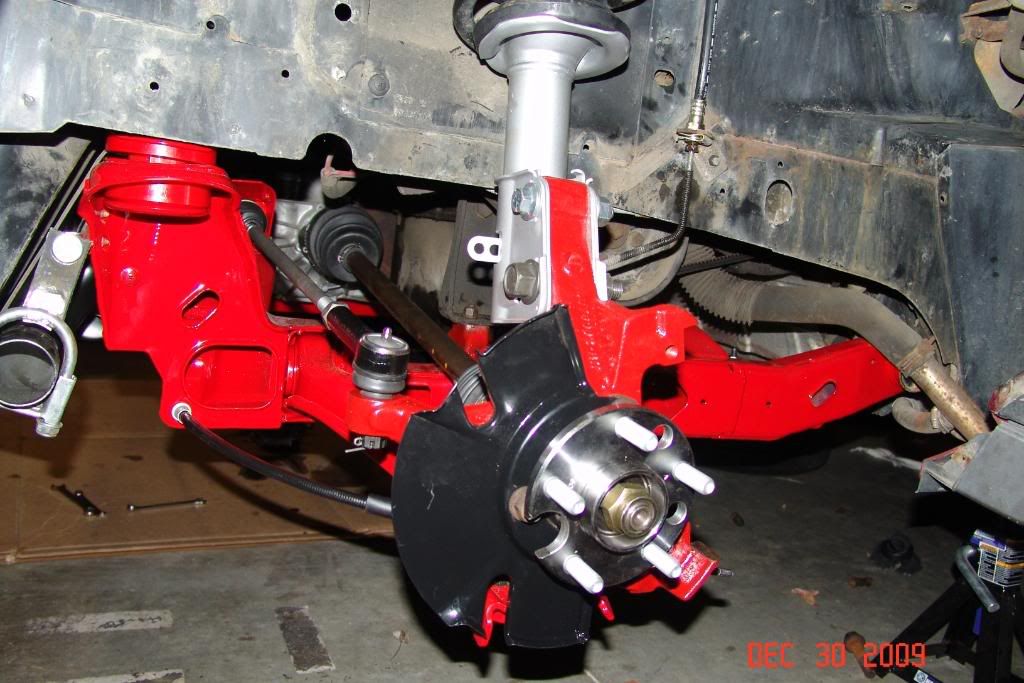

I replaced all the drivetrain components, motor and transmission mounts, exhaust etc. etc.

A few pics "in process" I wasn't really good about photographing as I went along, mostly because I didn't understand how to post pictures anyway so I just wanted some for me!

Transmssion back in place!!!

Had the air cleaner powder coated along with the cradle since it was a rusty mess too, other small parts are just painted, mostly to kill time while I waited on the tranny rebuild.

I went with the exhaust tips from The Fiero Store, I really like the way they look. The exhaust is Ocelot from The Fiero Store, sounds great and bolted right up.

What I've learned:

Transmission rebuild; 3rd gear grinding was a synchro issue, even with 112K the tranny was in "remarkably good shape" according to my transmision guy. I could have ordered a synchro and just replaced the one. However, while I was going to all this trouble I wanted to do as much of a full rebuild as I could. I got lucky, there was an export version of the HM282 for sale on e-bay and I bought one. I wan't sure I could swap out the internals, but turns out they are interchangeable except for 2 minor things. 1. Reverse select shaft is 1/2" shorter on the quad-4 variant (I think I read that on Rodney Dickman's site but forgot about it, Tom had to assemble it twice) and the ring gear from the quad-4 had to be bored out .020" to fit on the original spider gear assembly. I kept the original spider gear assemly so I could keep the stock speedometer setup. So what I have is essentially a brand new transmission n the car with lower gearing and a lower final drive. Oh, I almost forgt, I did keep the stock 5th gear set from original transmission and pressed it on the quad 4 output shaft to try and give myself a little taller overdrive gear for highway driving. All the gearing and final drive info can be found on Wikipedia or Rodney Dickman's website. If you are thinking about doing this kind of modification, I've put together a spreadsheet to analyze what the difference it and it boils down to this:

@4000 rpm which is about the peak of the powerband for the 2.8

Stock getrag vs. quad 4 Getrg

1st gear 23.07 mph vs. 19.63

2nd gear 39.40 mph vs 33.79

3rd gear 58.52 mph vs 53.62

4th gear 85.92 mph vs 71.84

5th gear 112.17 mph vs 102.77

Now, If I wanted to swap back to the stock final drive (3.61 instead of the 3.94 from the quad4) I would have the following:

1st 21.42

2nd 36.88

3rd 58.52

4th 78.41

5th 112.17

I have not really had a chance to drive the car enough since doing this to say what I think about the new gear ratios but the short time I have driven it I don't think they are too much different. I'll post more on the plus/minus side of this when the weather warms up and I can get it out on the road.

Some other things I've learned:

If you're doing transmission work replace the throwout fork and bushings, mine were shot. Clutch disengagement on my car is now at the top 1/3 of the pedal travel, the force to disengage is probably no more than 15lb (I plan to put a digital force meter on it and get a measurement, I'll post it when I get that done).

If you hear a sucking sound from the master cylinder while pressure bleeding the clutch line you are screwed for about 2 hours!

The clutch master cylinder does not hold much fluid at all, only about 2 full strokes of the clutch.

Pump bleeding and then gravity bleeding the clutch is the only way to get all the air out.

Bleeding takes about 30 minutes if you know what you're doing! Much longer if you don't.....

The Fiero Store is the only place to get rear brake calipers anymore, don't waste a week or two trying to get them locally, nobody has them and trying to R & R them will only get them sent back with a note saying parts are no longer available!

E-brake cables are not that hard to install and adjust, don't know what all the fuss is about.

Don't "burn out" rubber bushings from A-frames or the Cradle, just take an axle puller and put some "preload" on them, heat them with a torch and they will eventually begin to slide out. Doing it this way leaves a perfectly clean surface!

The Haynes manual says transmission mounting bolts should be tightened to 10 ft-lbs, this is WRONG, they should be 50 ft-lb.

A Getrag holds 2 quarts of oil, not 2.7 (haynes manual again, but on closer inspection the Getrag is not listed, only the "5 speed" which must be the Isuzu).

Fiero Store has been great, I've ordered almost everything from them, there are only a couple of things I had problems with. 1. The bushings for the throwout fork they sell are split steel with teflon coating, they didn't seem to fit right, Tom was more comfortable ordering oil-lite bushings isntead. 2. The camber adjusting bolts they sell for the rear struts I did not like at all, the type Rock Auto sells are much better to make the adjustment with and will give more camber adjutment. 3. The rear "tie rods" came with 12mm set screws with nuts as the connection hardware to mount to the cradle. Set screws are brittle as hell and should never be used for anything other than a "set screw" application, they are not meant to be put in any tension or twist loading. I put in some grade 8 bolts and cut the heads off instead of using them.

Use an engine hoist to hold up the engine while you're doing this (assuming you do it the "hard way" like I did). The engine support you can buy from The Fiero Stor (or elseware) will not allow you to easily raise and lower the motor which is necessary when trying to dismount and mount the transmission. I made this decision before I started unbolting things and was darn glad I did when I got to removing the transmission, there is not enough room to slide it completely out of the clutch disc unlss you lower the motor so the butt end of the transmission can clear under the space frame.

I'm sure I'll think of more things, but that's all for now.

Edit for one more comment:

Shift cables, particularly the select cable. Replace it, do it now, yours is shot if it's original. Rodney Dickman's is great, I bought one of his so I don't know about others but I would imagine they are fine too.

The select cable siezes/gums up over time and actually causes the damage to the third gear synchro, maybe 5th too, and that's all I have to say about that! (from Forest Gump if you're wondering).

[This message has been edited by Indiana87GT (edited 02-08-2010).]