Does trying to fix your broken Console Skeleton aggravate you? Have you tried every glue you can find but nothing seems to hold strong enough?

If any of this sounds like you, have no fear the solution is here.

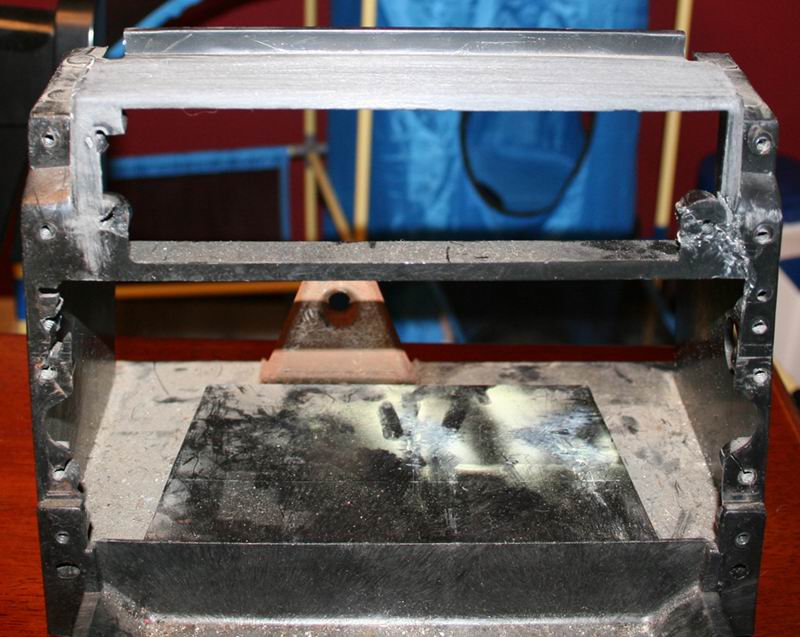

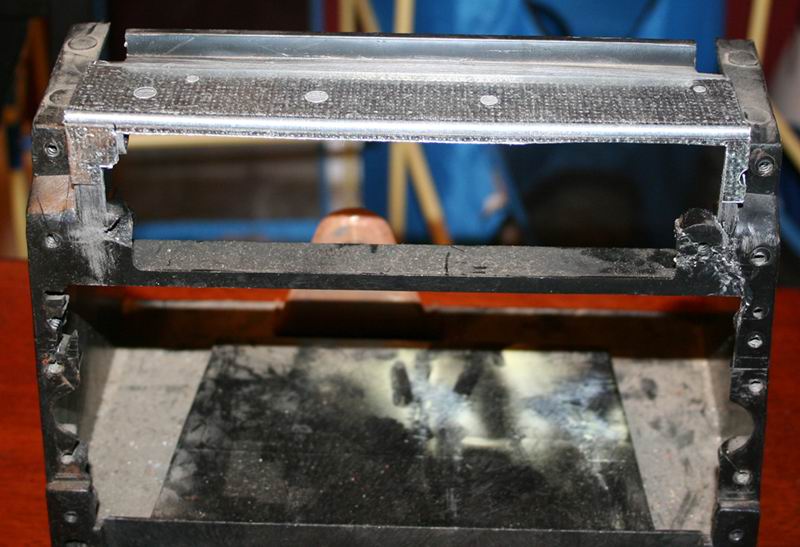

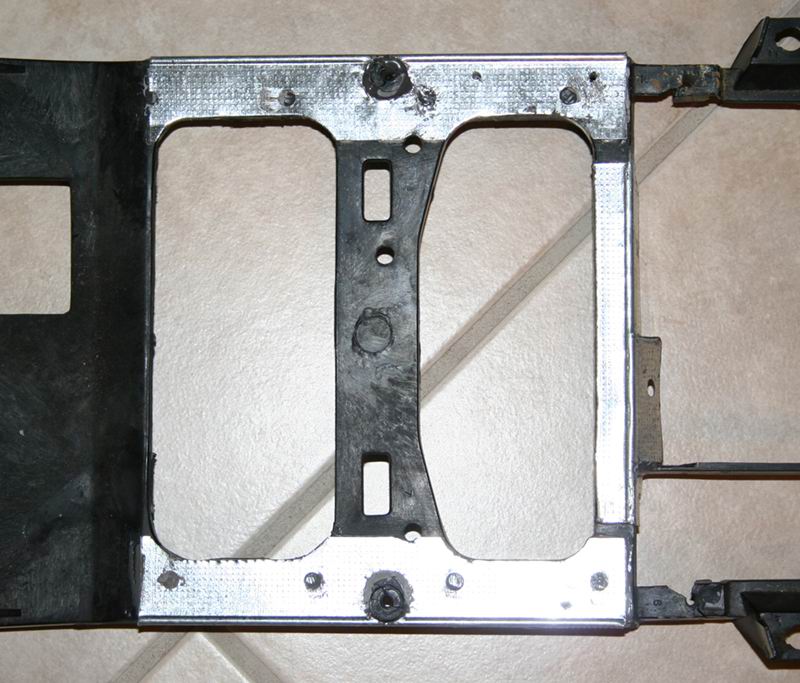

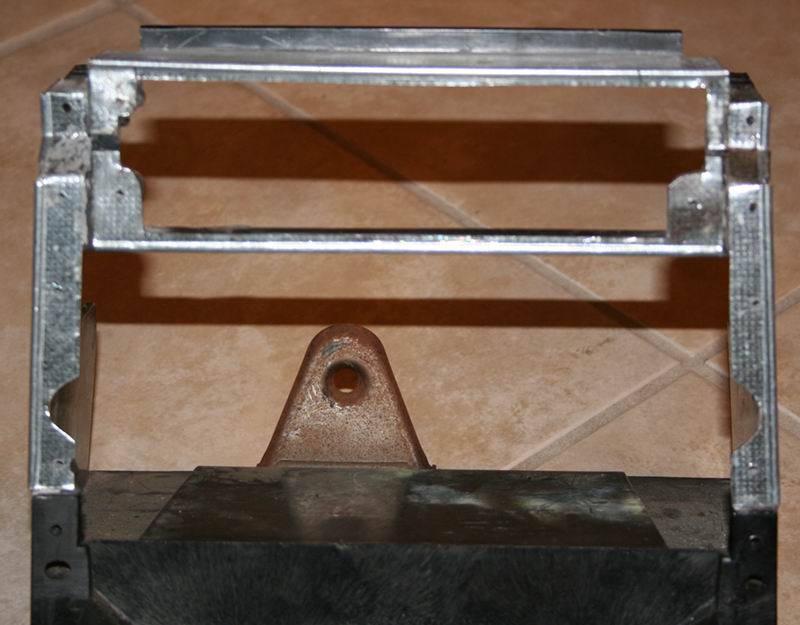

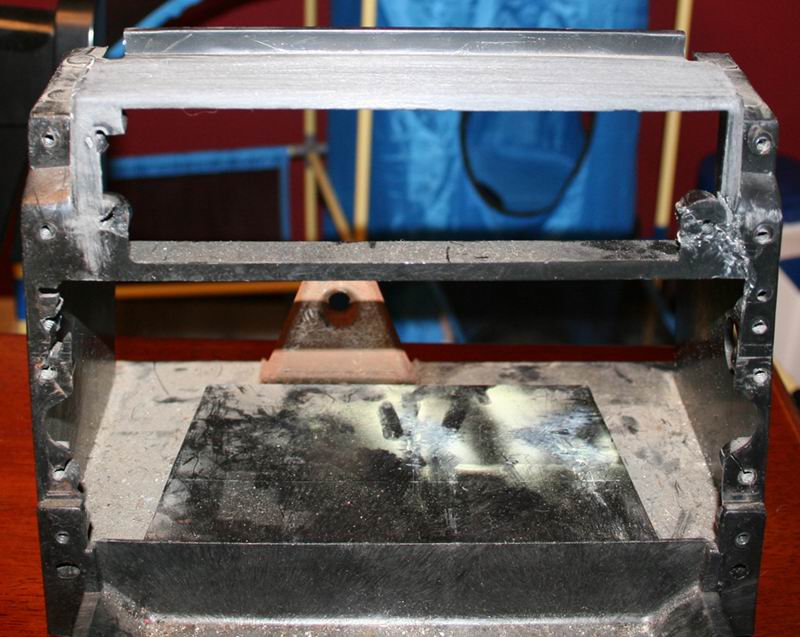

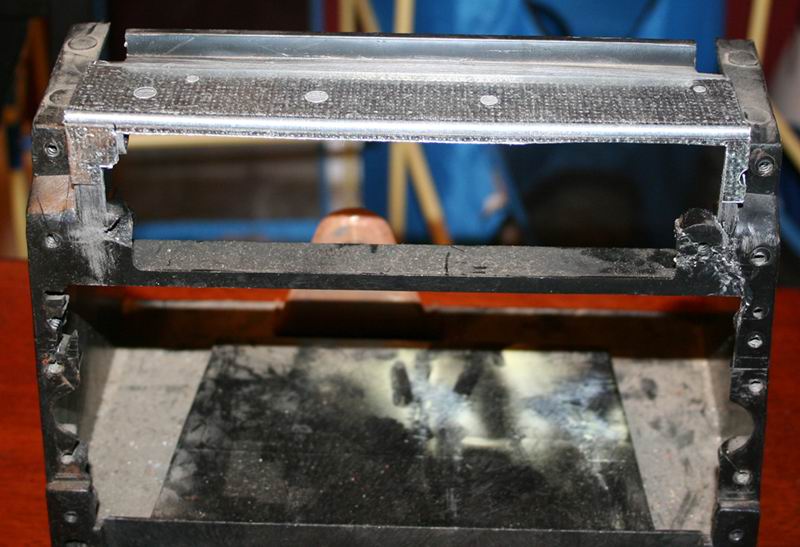

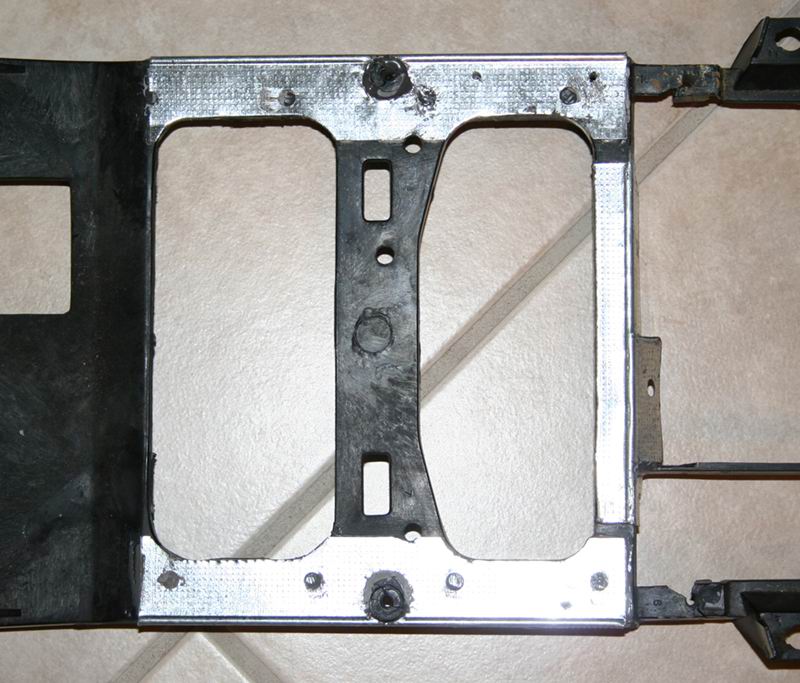

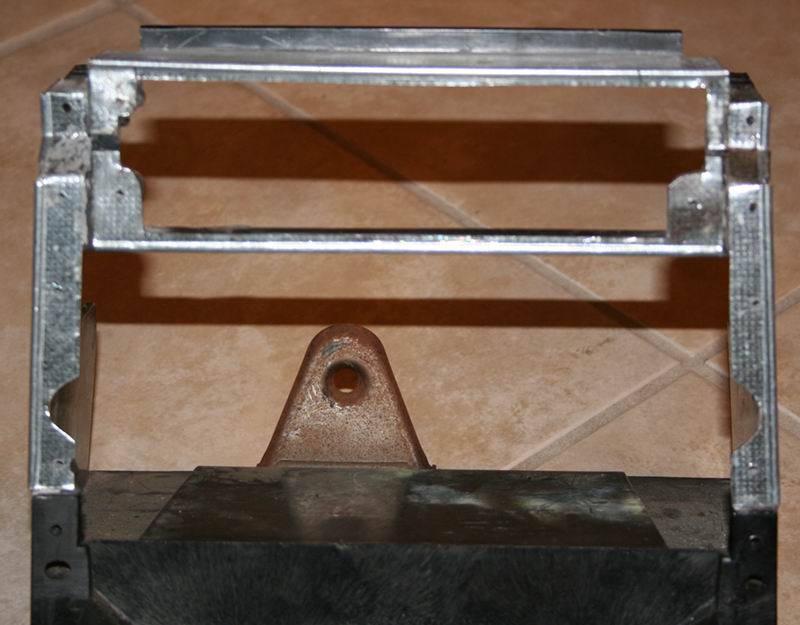

The goal of this project is to build a Console Skeleton "Exo Skeleton".

Here is what you will need to do this project...

1. Long piece of metal drywall corner bead.

2. Pair of tin snips

3. Super Glue gel

4. JB Weld

5. Fine Line Sharpie Marker

6. Pair of pliers

7. Razor knife

8. Spring loaded clamps

9. Piece of 120 grit sand paper

1st step is to use the super glue gel and glue the broken area.

2nd step is to sand the area where you will be bonding on the cut and shaped piece of metal drywall corner bead.

Next you need to cut and shape a piece of drywall corner bead to fit the area you want to repair. Use the pliers to make any 90* bends you need to make. Use the Sharpie marker to mark the metal where it needs to be cut.

Now you will need to mix some JB Weld and spread it over the entire area where you will be placing the metal. Place the metal in place and clamp it with the spring loaded clamps. The JB Weld take 15 hours to cure so this is a slow process to repair. Once it is dry, remove the clamps and move on to the next area. Use the razor knife to trim off any excess JB Weld that oozed out along the edges.

After you are done with all your repairs. You will need to use a 7/64 drill bit to drill pilot holes in the metal where all the original mounting points are.

Congratulations, you just repaired your Console Skeleton once and for all.

------------------

Click here for all your Fiberglass part needs

Click here for all your Fiberglass part needs[This message has been edited by JimmyS (edited 02-26-2011).]