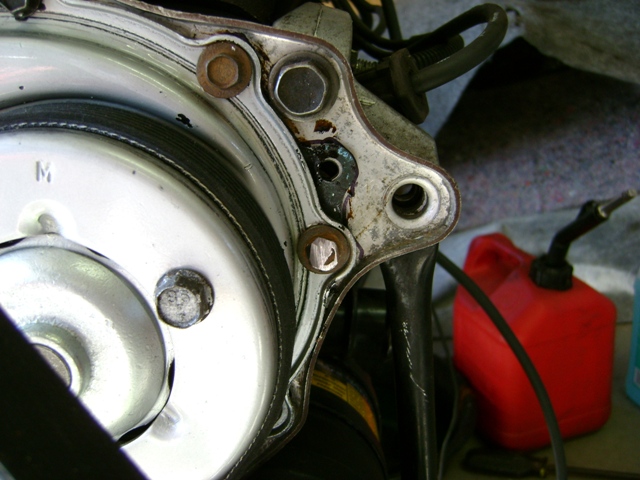

Pat, I removed the mount for the idler pulley from the Cadillac belt tensioner with a hack saw.

The stub is the correct dimension for the new idler pulley mounting hole.

I drilled out the stub so a 10mm bolt would go threw the center.

This was just short of 1/2". Some one here posted the space behind the pulley was about 1/2". Measuring the base of the stub, I added two flat washers behind it to make up 1/2".

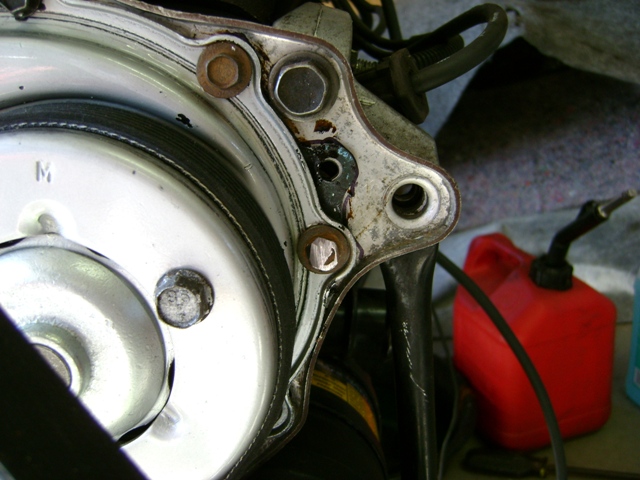

This bolt threads into the upright brace behind the water pump housing etc, while the lower end of the brace mounted to the AC compressor. Notice that I had to remove a bit off of one water pump bolt

Jam nut on the back so the bolt doesn't back out and get loose

I had noticed that the off set wasn't the same on both sides of the pulley, one way was just a bit different. You might need to try both ways to see which way is best for your set up.

[This message has been edited by josef644 (edited 03-13-2010).]