When we did the 4.9L swap into the Finale we were told that we needed the 4 cylinder throttle cable and it would bolt right up. No problem, I have 3-4 cylinder parts cars. Problem was, none of them would work. I found out later that you need a LATE 4 cylinder throttle cable, but we needed it NOW, so I made the 6 cylinder throttle cable work and it worked fine.

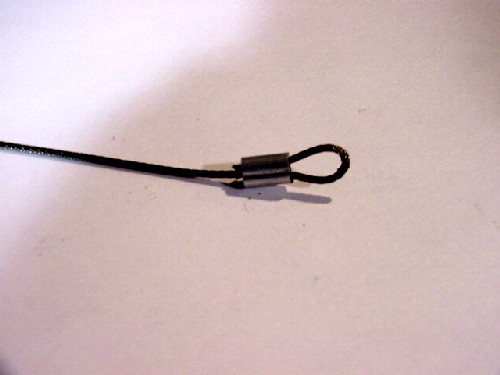

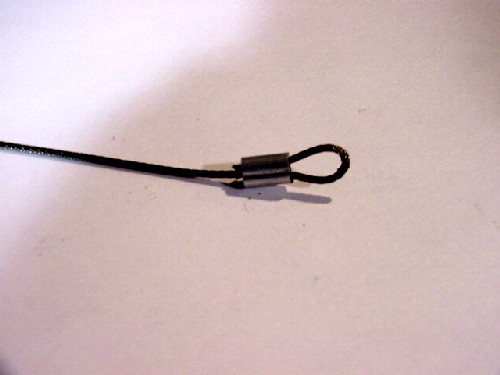

The first thing you need are some cable swage fittings. These can be found at a GOOD hardware store. Most likely you're going to need the smallest ones they have. I'd suggest that you get a few of them so you can practice crimping them so you know how far to crimp as you can go too far. Your primary one that you need is a double cable swage and it looks like the one on the left in the following two pictures.

Neither of the pictures above show the proper sized swage fitting because the bigger ones photograph better, but they look identical except for the size of the holes for the cable and the overall size of the fitting.

These pictures show two fittings, one a double hole fitting and one a single hole fitting. The double is the one you want to use to make a loop in the end of the throttle cable.

Here's a picture of the V6 throttle cable. Start by cutting the metal loop at the end of the cable off leaving as much cable as possible sticking out of the sheath. You want to cut JUST THE METAL LOOP OFF and no more cable. Make a nice, clean cut on the cable so it doesn't fray. A good, sharp pair of diagonal cutters will work just fine.

Now you need to make a loop in the throttle cable. Pass it through the swage fitting, loop it, and then through the other hole so it looks like this

Lay the cable and loop in the 4.9L TB with the plastic in the stock 4.9L retainer and check your length. You want it to lay in there easily. You have a LOT more travel on the throttle pedal and cable than you need for the 4.9L, so as long as it lays in there nicely, you'll be fine. If you can, make it so the loop just lays in loosely and you have excess sticking out behind the swage.

Now you need to swage (crimp) the fittings. This is not unlike crimping an electrical connector. The fittings are soft aluminum and the small ones you'll be using are easily crimped with electrical crimpers. In fact, you need to be careful that you don't crimp too tight and break the fitting. Just get a nice, tight crimp. You might want to buy some extra fittings (they're very cheap) and practice before you do your cable.

If you have enough cable sticking out behind the fitting, you can use a single hole fitting and crimp it on there as well so that you know it will never come loose. These fittings are small enough they will lay in the groove of the 4.9L throttle body actuating cam.

I used a stainless steel, button head, allen machine screw that I cut off to the proper length with a standard nut and a star washer. I also put a drop of loctite on the threads. Remember to pass the screw THROUGH the loop of the cable. I also used the screw to size the loop when I made it so that I knew the screw would slip through the loop easily when I got ready to put it on the throttle body.

We've driven the car about 1500 miles so far and almost 300 on track day at Wheatstock and the screw and cable show no signs of wear. You'll get full throttle well before the throttle is on the floor so you might want to fab a throttle stop at the pedal to keep from stretching and abusing the cable.

BTW, you can also use the simple, single hole fitting to take up the slack on your stretched throttle cables in stock applications. Just cut the stock end off and put the new one on. You can double them up if you think you need to, but once properly swaged, they're almost impossible to get off.

John Stricker

but they are by far

but they are by far