|

| LS4 / F40 swap - fieroguru (Page 152/197) |

|

fieroguru

|

APR 12, 07:22 PM

|

|

Heads installed and torqued down - I stuck with factory 5.3 head gaskets and GM bolts. Torqued to 22 ft lbs, 90 degrees 2nd pass, 70 degrees final pass.

Rockers installed and torqued. The CNC porting opened up the base of the rocker bolts in the intake ports, so I had to shorten the bolts (removed the unthreaded nubs from the ends) and installed the bolts with sealant.

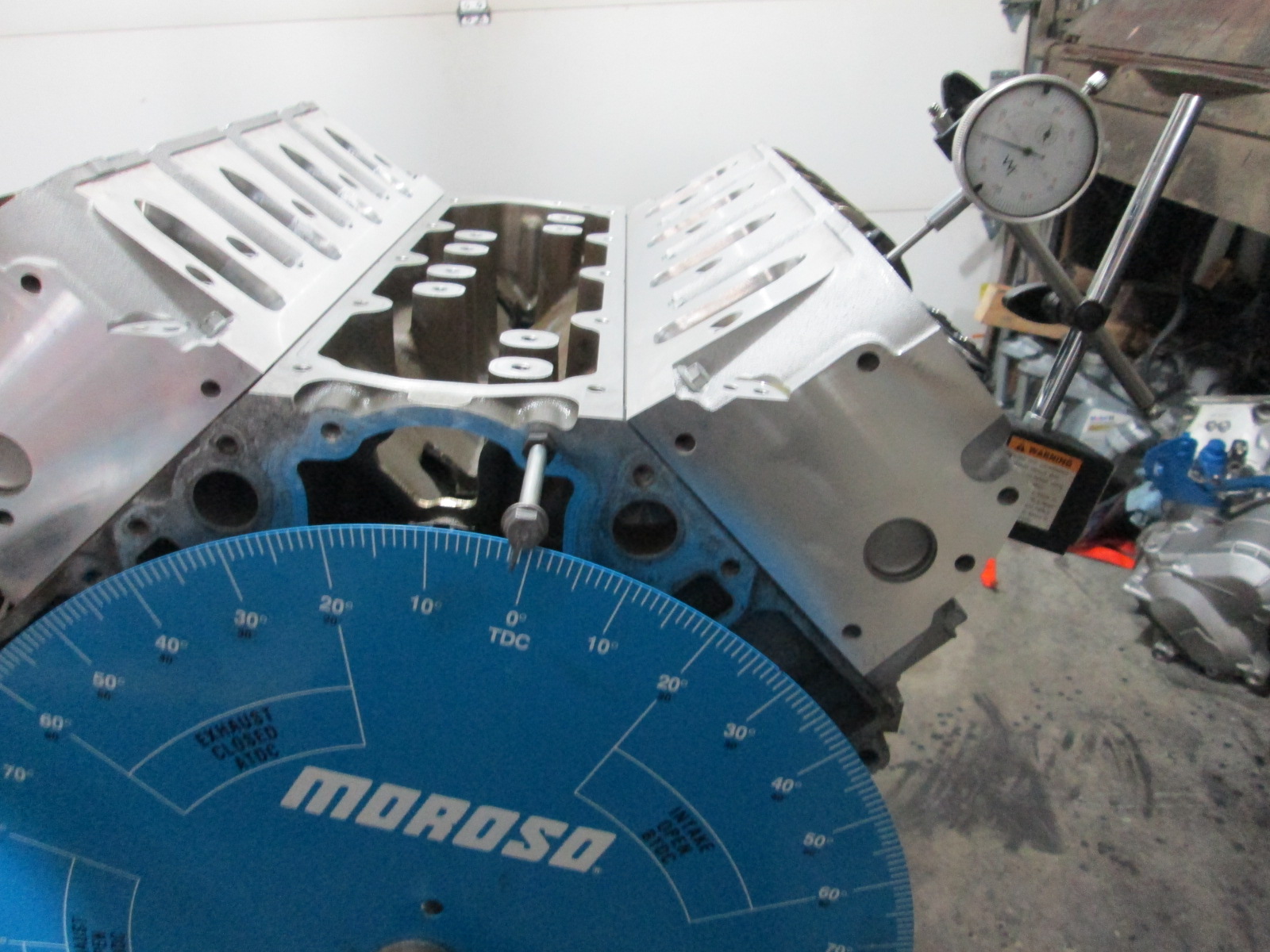

Camshaft degreed in with it installed dot to dot. The valve events were right where they are supposed to be. I will say the springs and lift are noticeable with hand turning the engine, lots of little spring pulses are each lobe goes to peak lift. Here are a couple of reference pictures showing the setup. Intake valve open @ .050"

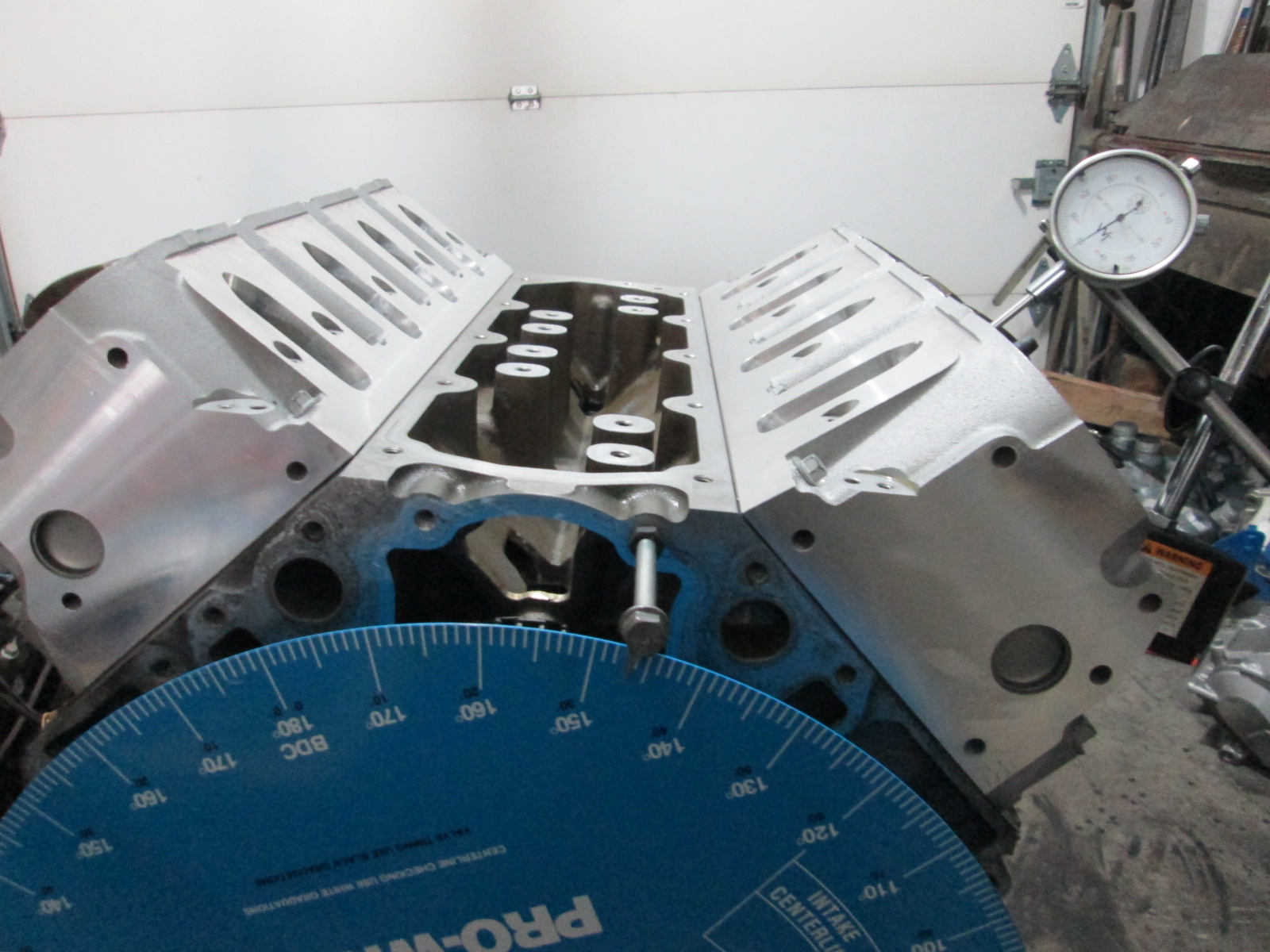

Exhaust valve open @ 0.050":

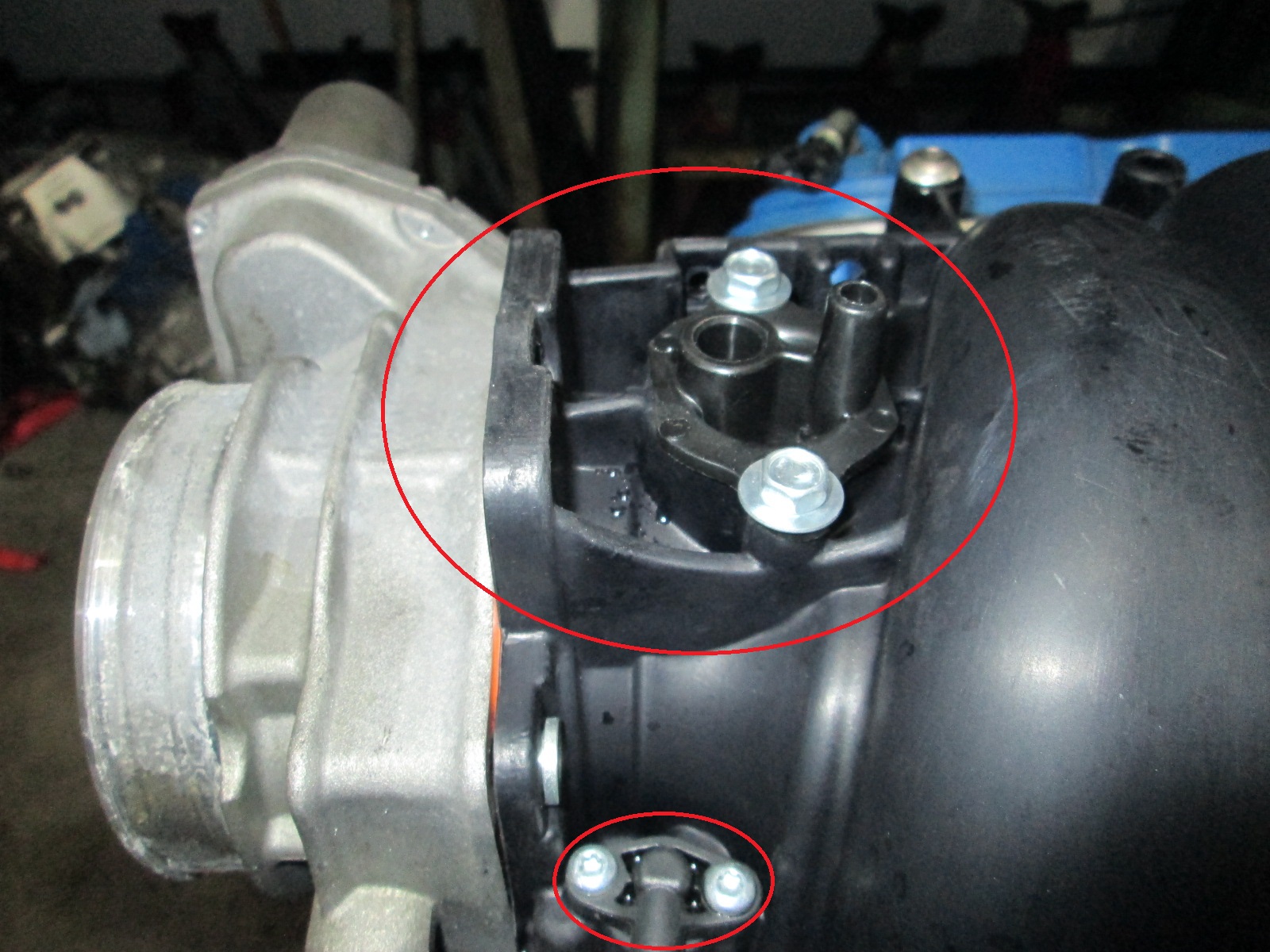

Since DoD was eliminated, I went with a factory LS2 valley cover, but I just had to make a few tweaks to it. First I cut down the OPSU boss about an inch and tapped it (might just plug this hole or use it for an oil feed to the turbo). The second modification was counter sinking all the bolt holes and adding stainless steel hardware, last modification was sanding down the sides to smooth the casting parting line flash. Not sure if this will be painted blue or aluminum at this point, so consider this a temporary install. This picture also shows the tape on the heads and the ports cut out. I will eventually used these to help verify port alignment with the intake.

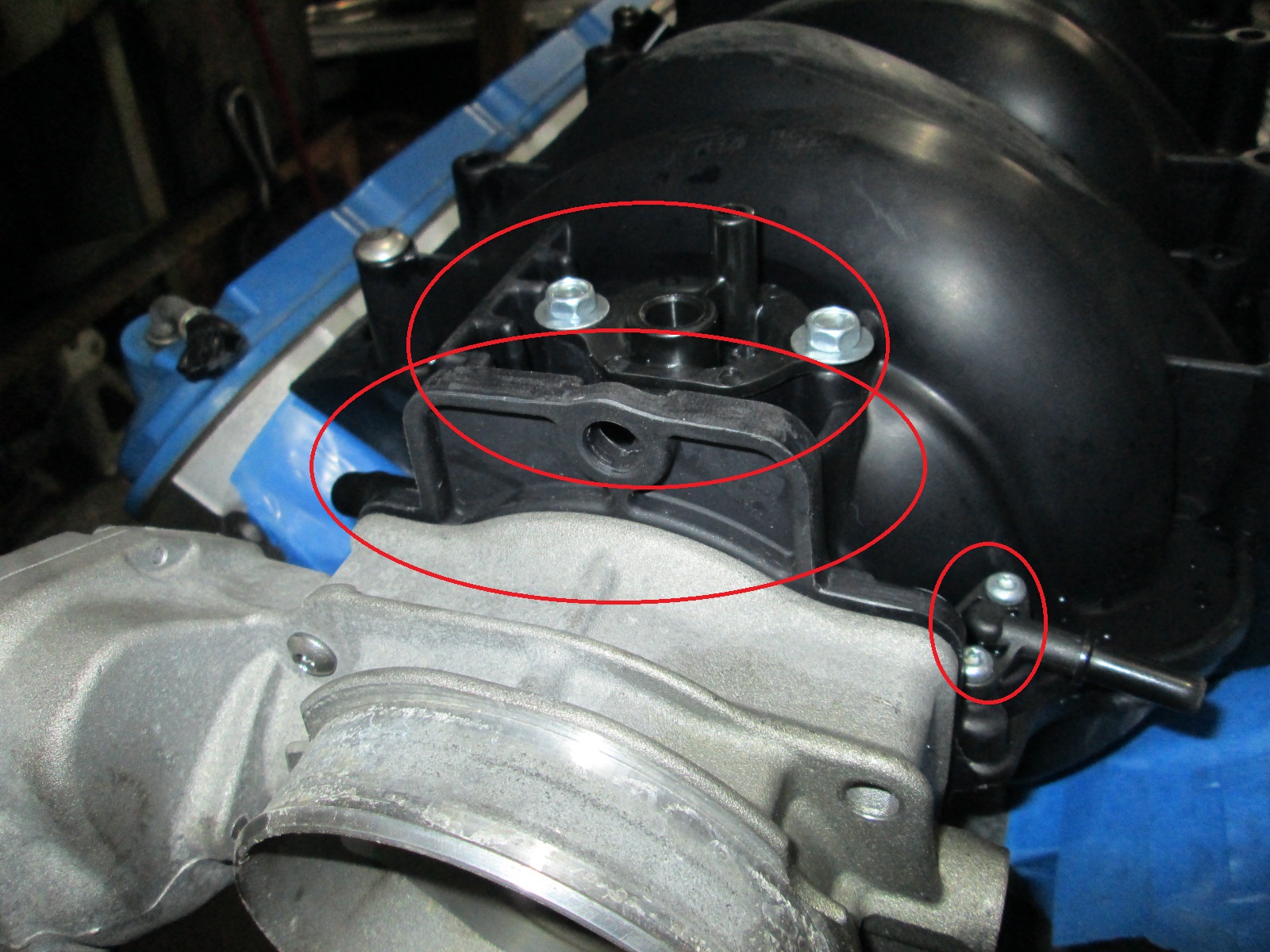

Then I started playing with the Dorman LS2 intake and making mental note of all the areas it will be modified, most of these are just to improve the visual appeal of the intake. There are several groups of modifications:

1. Intake bolt boss shortening. This needs done to reuse my modified bolts from when I did this to the original LS2 intake (they are too short with the stock height boss). The aftermarket fuel rail also wont fit on the injectors as it hits these bolt bosses as well.

2. Dorman probably figured that everyone runs an engine cover, so they literally wrote a book on nearly every surface of the intake they could. All of this has to go. There are also some areas were material extends and it doesn't have a purpose, so those need to go as well. Then there are some areas that would look better with the casting flash removed. Overall there just is a lot of smoothing in order. The scuffed areas on the runners have already had some text removed.

3. Universal usage fugliness... This intake is for the LS1 and LS2, so it has mounting provisions for the LS1 throttle body, the egr port, and alot of ugliness... All this will be cut down and cleaned up.

Once I address the aesthetic issues with the intake, then I can focus on some minor porting...

It was good to have some time away from work and customer orders to actually make some progress on my own Fiero!

|

|

|

Trinten

|

APR 12, 08:37 PM

|

|

Looking very nice man!

I take it you are not concerned about boost going through the Dorman intake? I know it's my paranoia, just seemed like a bad idea to have something that normally saw ambient to negative air pressure to see positive pressure.

|

|

|

ericjon262

|

APR 12, 08:39 PM

|

|

| quote | Originally posted by Trinten:

Looking very nice man!

I take it you are not concerned about boost going through the Dorman intake? I know it's my paranoia, just seemed like a bad idea to have something that normally saw ambient to negative air pressure to see positive pressure. |

|

People do it all the time, and push a ton of boost through them. the only failure I've seen, was a truck intake that all of the reinforcements were shaved off of. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

fieroguru

|

APR 13, 08:50 AM

|

|

| quote | Originally posted by Trinten:

I take it you are not concerned about boost going through the Dorman intake? I know it's my paranoia, just seemed like a bad idea to have something that normally saw ambient to negative air pressure to see positive pressure. |

|

I am only planning to run 7-10 psi boost. There has been 1 reported failure on the LS6 version (earlier version) at 15 PSI. It separated right behind the throttle body area at the seam. So far, I haven't seen any failures reported on the LS2 version, but time will tell. I want to keep the stock sleeper look and most of the other intake options either hurt low RPM toque, have also been popped, weight too much, or are too expensive.

|

|

|

wftb

|

APR 13, 09:21 AM

|

|

|

The intake on my ecotec came from an NA 2.4 ecotec. People have boosted it to 20psi. Pretty good for a piece of plastic. After that, they may split open. Way more boost than I will ever use, I usually run at11psi max. ------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms

|

|

|

Will

|

APR 13, 10:11 AM

|

|

The 996 front diff includes a viscous coupling in the driveshaft. SOME type of center diff is necessary, as the Saab gear train does not include any.

I've heard things that the 996 doesn't do a very effective job of putting power to the front tires... like YouTube videos of AWD 996's stuck in the snow without the front tires spinning... although the front diff is open so the video might not catch the other side spinning.

|

|

|

fieroguru

|

APR 13, 05:47 PM

|

|

| quote | Originally posted by Will:

The 996 front diff includes a viscous coupling in the driveshaft. SOME type of center diff is necessary, as the Saab gear train does not include any.

I've heard things that the 996 doesn't do a very effective job of putting power to the front tires... like YouTube videos of AWD 996's stuck in the snow without the front tires spinning... although the front diff is open so the video might not catch the other side spinning. |

|

My plan has always been to run a 1 way clutch in the drive shaft to the front diff. With the smaller front tires, the front will always over run (rotate faster than) the rear. When there is zero slip at the rears, the front just spin as normal w/o any power applied (they are effectively being pushed faster than the engagement RPM of the power). When the rears do slip (on hot dry pavement), and try to rotate faster than the fronts, the 1 way clutch will engage and send power to the front wheels. The fronts will then try to put an end to the wheel spin while helping to pull the car in the right general direction. One the rear slip subsides, then the fronts go back to their free wheeling... that at least is the thought/theory... Simple 100% mechanical AWD on demand w/o the typical binding in parking lot maneuvers.

|

|

|

qwikgta

|

APR 14, 10:46 AM

|

|

Great looking setup, love the attention to detail. A few questions for my own LS4 build, I noticed you tapped and plugged the holes used for the DoD lifters. Is that required? When I remove my setup, will I have to tap/fill those as well? what about the o-rings that would normally be there, do I need to worry about oil flowing out of the holes?

Also, noticed you still have the oil fitting on your valley cover, do you need this if your using your oil adapter, the one that installs near the oil filter? I was under the impression that I could use a valley cover without the oil fitting by using your adapter?

Thanks in advance.

Rob

|

|

|

fieroguru

|

APR 14, 01:18 PM

|

|

| quote | Originally posted by qwikgta:

Great looking setup, love the attention to detail. A few questions for my own LS4 build, I noticed you tapped and plugged the holes used for the DoD lifters. Is that required? When I remove my setup, will I have to tap/fill those as well? what about the o-rings that would normally be there, do I need to worry about oil flowing out of the holes?

Also, noticed you still have the oil fitting on your valley cover, do you need this if your using your oil adapter, the one that installs near the oil filter? I was under the impression that I could use a valley cover without the oil fitting by using your adapter?

Thanks in advance.

Rob |

|

Rob, there are a lot of things I do that are definitely not required, some are to get a specific look (like all the mods to the dorman intake) and some are for personal preference.

Tapping the DoD pedastal port is one of those. As long as you get a valley cover with the built in o-rings to seal those passages, you will be good. There is another potential modification that might require me running a thinner valley cover, which might not be able to apply enough pressure to seal the DoD o-rings. Since I had the camshaft out, tapping them seemed like the practical thing to do and it avoids any potential o-ring failure 10-15 years down the road.

Keeping the OPSU boss is another one. You don't need to keep it. There are billet versions that have it completely blocked off, but I like using GM parts as much as possible, and pretty much every one of them has the OPSU. I shortened it so it doesn't get in the way anymore, but left enough material I could either put a NPT plug in it or use it for the oil feed to the turbo... not sure which way I am going, but left myself options for either path. If I need a thinner valley cover, then I won't even use this one...

|

|

|

qwikgta

|

APR 14, 08:47 PM

|

|

|

|

|