|

| LS4 / F40 swap - fieroguru (Page 145/197) |

|

fieroguru

|

SEP 29, 10:34 AM

|

|

One of these things is not like the others...

DoD lifter failure on the #7 exhaust valve. I knew it would happen someday, but glad it lasted 6.5 years, 55K mile (+ 18K miles before swap), and hundreds of WOT pulls to 7000+ rpm. Now I won't feel bad taking the car off the road for a little bit and doing some performance upgrades.

The current upgrade list:

1. DoD delete - all needed parts are now sitting on the shelf.

2. Camshaft swap. Tick Stage 2 Turbo camshaft for the 4.8/5.3L engines, 219/223 .617/.595 LSA114+3, sitting on the shelf

3. Dorman LS2 intake manifold. Sitting on the shelf

4. Flex fuel conversion. Flex fuel sensor and the Fierostore stainless steel sender are on the shelf.

5. Rework as many brackets, mounts, and smooth firewall panel in aluminum to help shed some weight.

6. Change the ECM to a RWD/6 speed manual ecm. This will allow me to remove the TCM and assorted wiring and likely remove my old school cruise module (weight savings).

7. Mockup and test fit Borg Warner SXE-369 turbo.[This message has been edited by fieroguru (edited 09-29-2019).]

|

|

|

motoracer838

|

SEP 30, 04:27 PM

|

|

Upgrade...

It was good that the lifter failed after the Power Tour...

Joe

|

|

|

Will

|

SEP 30, 04:29 PM

|

|

| quote | Originally posted by fieroguru:

One of these things is not like the others...

DoD lifter failure on the #7 exhaust valve. I knew it would happen someday, but glad it lasted 6.5 years, 55K mile (+ 18K miles before swap), and hundreds of WOT pulls to 7000+ rpm. Now I won't feel bad taking the car off the road for a little bit and doing some performance upgrades.

The current upgrade list:

1. DoD delete - all needed parts are now sitting on the shelf.

2. Camshaft swap. Tick Stage 2 Turbo camshaft for the 4.8/5.3L engines, 219/223 .617/.595 LSA114+3, sitting on the shelf

3. Dorman LS2 intake manifold. Sitting on the shelf

4. Flex fuel conversion. Flex fuel sensor and the Fierostore stainless steel sender are on the shelf.

5. Rework as many brackets, mounts, and smooth firewall panel in aluminum to help shed some weight.

6. Change the ECM to a RWD/6 speed manual ecm. This will allow me to remove the TCM and assorted wiring and likely remove my old school cruise module (weight savings).

7. Mockup and test fit Borg Warner SXE-369 turbo.

|

|

Is your engine a 24x or 58x?

|

|

|

fieroguru

|

SEP 30, 06:49 PM

|

|

| quote | Originally posted by motoracer838:

It was good that the lifter failed after the Power Tour...

Joe |

|

It made it through the HRPT of 2016, 2017, 2019. I have driven the car about 3K miles since the HRPT this year. Of course it broke 2.5 hrs from home on my way to work. So had it towed to the in-laws, picked up a rental, came back with my truck and tow dolly, and took it home. Been working on clearing out space in the garage to pull it back in for the repair and other work.

I do wish it would have lasted a few more weeks. I was registered for a HPDE event on the 12/13th of October.

| quote | Originally posted by Will:

Is your engine a 24x or 58x? |

|

The engine in the car is 58x, but I also have one of each on the shelf as well.

|

|

|

Will

|

OCT 01, 09:08 AM

|

|

|

The '09 Trailblazer OS can take direct-wired cruise control without needing a BCM. Not sure if that's what you had planned or if you were looking at another option.

|

|

|

sourmash

|

OCT 01, 10:48 AM

|

|

Yeah, that was good service life.

PM sent.

|

|

|

Will

|

OCT 05, 04:01 PM

|

|

| quote | Originally posted by fieroguru:

Found it:

3 wire LS1 temp sender GM # 12551708, application 1998 Camaro w/ LS1, pigtail is the same as the TPS sensor on the fiero 2.5 and later model applications.

The bottom wire is for the gauge.

Only downside to using this 3 wire setup is I will loose the temp light, but the gauge is much more important anyways. I like the idea of 1 less sensor.

|

|

Is this pinout is looking at the mating face of the connector?[This message has been edited by Will (edited 10-05-2019).]

|

|

|

fieroguru

|

OCT 07, 12:17 AM

|

|

| quote | Originally posted by Will:

Is this pinout is looking at the mating face of the connector?

|

|

I think it is the face of the connector (vs. the face of the sensor), but I will need to check the service manual when I get back home this coming Friday...

|

|

|

Will

|

OCT 07, 08:34 AM

|

|

We just swapped my dad's truck* from two wire sensor + original gauge sender to the three wire sensor/sender combo. We figured it out.

* Truck = 1990 3/4 ton Suburban, original diesel chassis, now with 3.21:1 14bff rear, Cadillac 500 and 4L80E trans. We run '90's LT1 controls via the optical trigger wheel mounted in the bottom of a large case HEI distributor.

|

|

|

fieroguru

|

OCT 13, 03:32 PM

|

|

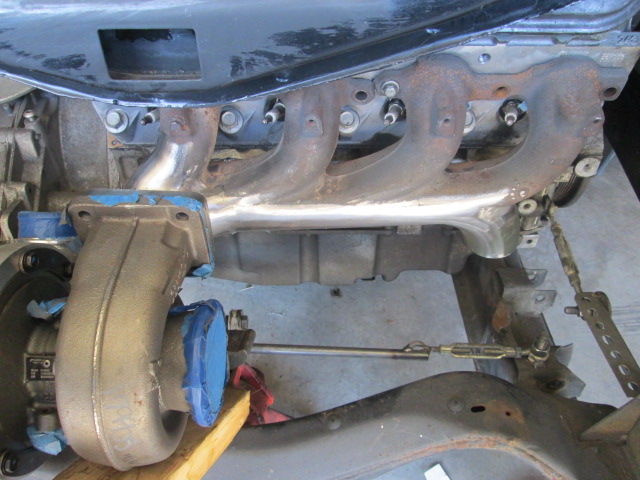

Over the past several weekends, I have been slowly working on the turbo manifold, and it has been a lot of work, but I am pretty happy with it.

Started with a truck manifold from the passenger side, cut the bottom half of the main tube off. Took some 2 1/2" back pipe, cut it a little longer than needed, cut out about 1/3 of the circumference the length of the pipe, then trim, trim trim until it would mate up well with the truck manifold. I use the vice to give it a taper as the exit end is larger and I wanted a smooth seem between the two pieces. I used a combination of 2 1/2", 2" and 1 1/2" elbow that were cut and shaped to smooth out all the transitions starting with the front bank tube all the way to the end where the T4 flange will be welded on.

Lots and lots of cutting, grinding, welding and more grinding got me to this point.

I bolted the manifold to one of my spare/junk heads and welded everything up. I started with a root pass along the seam, only doing about 2" at a time before jumping to the next section. Followed that up with a heavy top weld with about 1/8" overlap past the base material on each side. I went as fast as my 220V welder would allow, which kept the manifold quite hot through the top weld portion. Then I let it cool while I mowed the grass.

Removed the manifold and is was still flat at the head, which is good.

Then back to grinding....

I still have a lot of work to finish the smoothing process, but it is starting to look like a turbo manifold.

|

|

|

|