|

| ecotec swap (Page 90/98) |

|

longjonsilver

|

SEP 08, 08:54 AM

|

|

Doing my preliminary research on the ecotec engine, i read the thread about the 1800 Volvo and have read your thread and the other ecotec threads her on this forum. i also read threads on ecotec forums. i have noticed that the LE5 motor is available cheaply in the scrap yards, with the 5 speed tranny and superchargers for the ecotec run about 250. Apparently the LE5 motor can be supercharged to around 250hp before major engine mods need to be done, due to the rods used in the motor. i remember that you interchanged various ecotec motor parts to build the motor that you use now. What are your thots about going this route?

jon

edit: my car seems to handle better now that ive installed the 3 core radiator instead of the single core radiator that it came with - more weight right on the nose.

------------------

Astronomy says we will find a coded signal from outer space. Then we'll KNOW that life exists there, for coded signals aren't by chance.

Biology says there are coded genetic signals in every cell, but we KNOW that no intelligence created life.

I'm the original owner of a white ' 84 2M4 purchased Dec 10, 1983 from Pontiac. Always garaged, no rust, 4-wheel drifts are fun![This message has been edited by longjonsilver (edited 09-08-2018).]

|

|

|

wftb

|

SEP 08, 02:17 PM

|

|

The first production LE5 motor is a very good engine. It came with better rods,pistons and crankshaft than later versions. I am talking about the version that was in the Solstice, Sky and the base motor in the Cobalt SS. The early L61 ecotec electronics will not run this engine because it has a different reluctor wheel. But the strong bottom end makes it a good choice for a turbo because you do not need any internal mods to boost it.

The engine in my car has Eagle rods and Wiseco pistons and a head gasket from an LSJ.The rest is all stock first gen 2.2. Because the present engine was from an automatic car, I had to use the water pump piping from my old engine. I also used the oil pan because the new engine's pan had a hole in it.

The superchargers that are available used are either take off's from LSJ motors or they are from the kit that GM sold for the cvalier/sunfire/cobalt 2.2's. These kits came with new injectors and a tune that got downloaded in to the car at a GM dealer.

Stock 2.2 engines have no problem handling the kind of boost from these superchargers. It is when you run a lot of turbo boost or nitrous that the weak link in a 2.2 gets exposed: the ultra thin upper ring lands of the pistons. But if you do a turbo setup and do it right you can keep a 2.2 together at sub 300 HP levels in stock form. Keep the boost down to 8PSI, intercool it, bigger injectors, an FMU and watermeth injection is one way to do it.

The stock LSJ head gasket has proven to be the way to go for boost. Better and cheaper than aftermarket head gaskets.

Do a search on member 4thfiero. He has a turbo LE5 with Alphafab engine management.[This message has been edited by wftb (edited 09-09-2018).]

|

|

|

Lunatic

|

SEP 09, 07:43 AM

|

|

| quote | Originally posted by longjonsilver:

Perhaps if the gages thing is resolved...

jon

|

|

Jon,

Yes, WFTB used the OEM Cavalier instrument cluster in his swap. Is this something that you don't like?

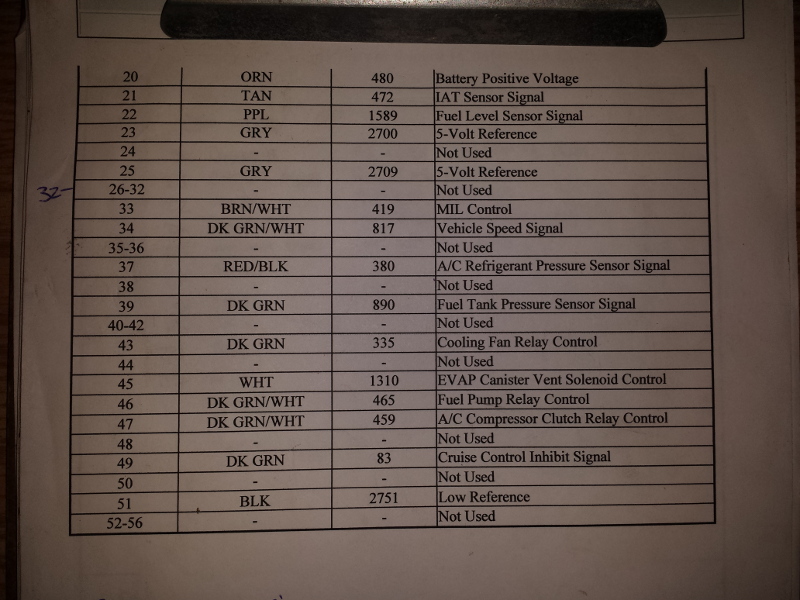

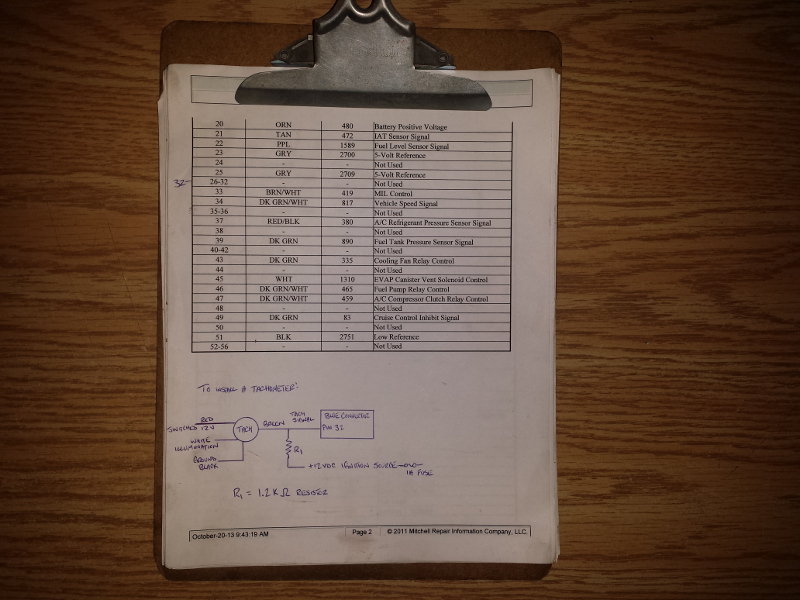

I too have a running Ecotec (L61)/F23 swap in my car. I went the other direction and used aftermarket gauges in my car. I clearly showed how to wire up a tachometer using a pull-up resistor using the stock PCM. I also modified the Fiero sending unit using late model Suburban guts and now have a functional fuel gauge. (See my thread for more information).

In case others out there are thinking of swapping in an L61 Ecotec, here is a snippet of information (from my swap) regarding how I resolved the Ecotec tachometer signal.

Steve, let me know if you don't want this in your thread and I'll remove it.

As you know, I've swapped in a 2.2 Ecotec into this car. Since I'm using the stock PCM and BCM, and not the Cavalier cluster, I needed to make the Equus aftermarket tachometer work with the Ecotec. Here's how I did it.

By looking at the 2003 Cavalier wiring schematic, a tachometer trigger signal is sent by the PCM through the serial data line and to the cluster where it's converted.

Since I'm not using the Cavalier cluster, I had to go about this another way.

Looking at the PID value charts was useless as it merely states, "Not Used" on several pins.

By using an oscilloscope, each pin labeled "not used" was checked.

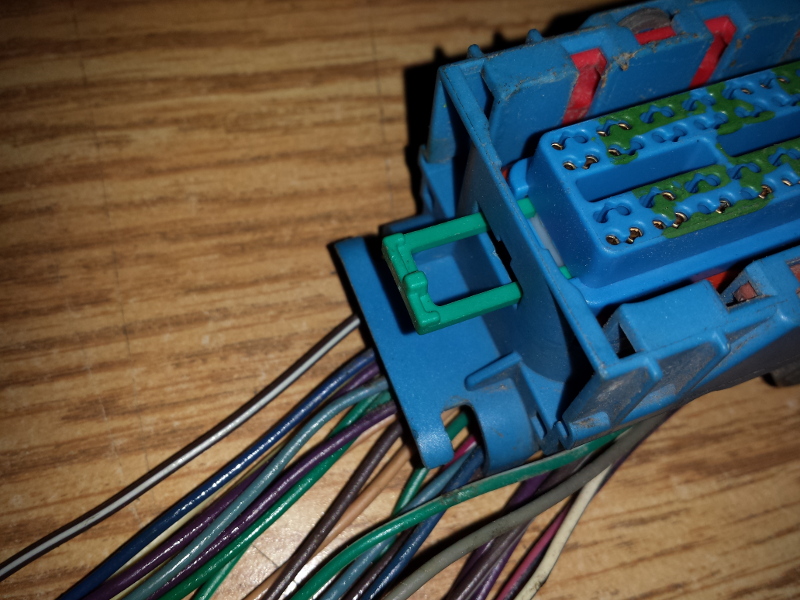

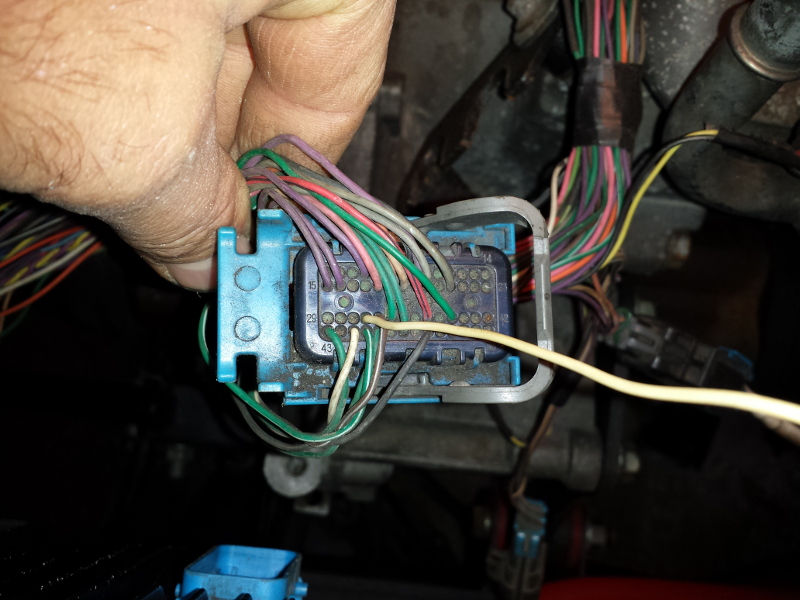

Success was present when pin 32 on the blue connector showed an open collector output for a tachometer.

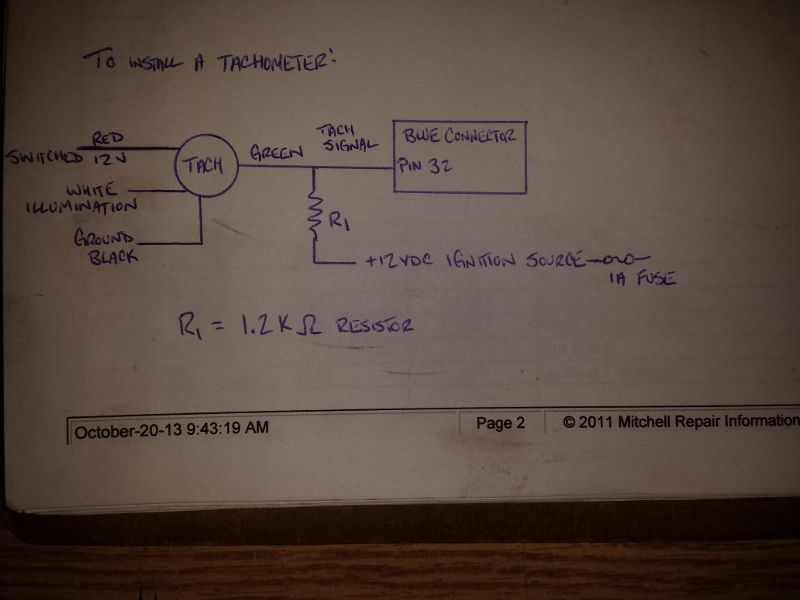

Since I had an aftermarket tach that doesn't have an internal "pull-up" resistor, I had to add one.

Note: I didn't have a 1K ohm (1000) resistor handy but I had some 1.2K (1200) ohm resistors in my collection.

The pull-up resistor pulls the open (collector) output up to +12V.

When the output transistor turns on, its collector terminal is connected to ground.

Hence the output is a square wave from near-ground to near +12V.

Here's the schematic that made it all work, simple really.

Note: My PCM part # is: 12576162

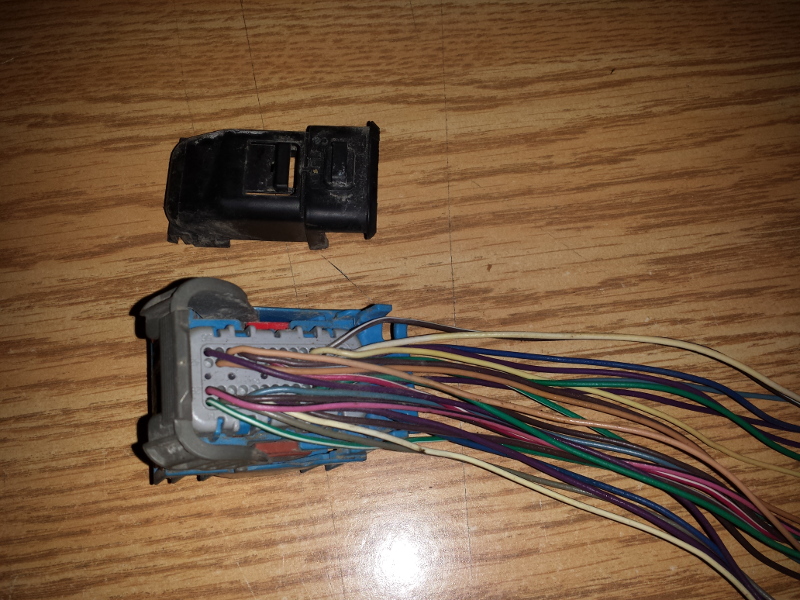

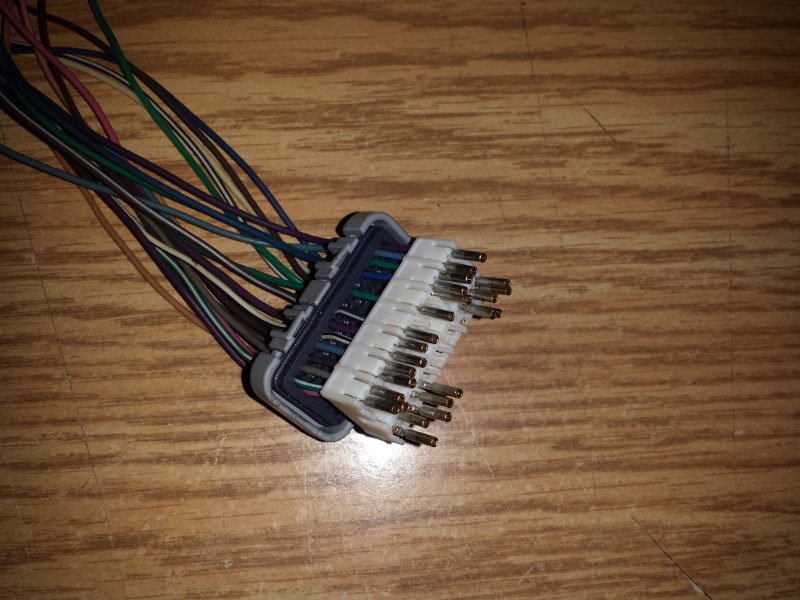

Since pin 32 was not used, there was no wire coming from the connector. I took another PCM harness pig tail and removed a white wire.

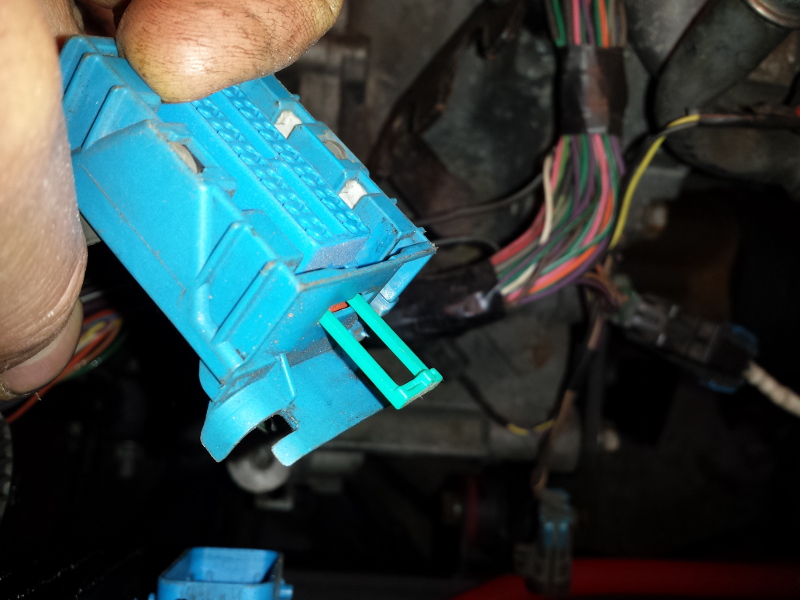

Remove the turquoise clip and unlock the connector.

This leads to exposed terminals and wires. I took a white wire just because.

On the car, I had to undo the clip and disassemble the connector.

Since cavity 32 was unused, I had to drill a small hole in order to place the connector through.

Here, you can clearly see the white wire protruding from cavity 32 on the blue connector.

I extended this new white wire to the stock Fiero harness.

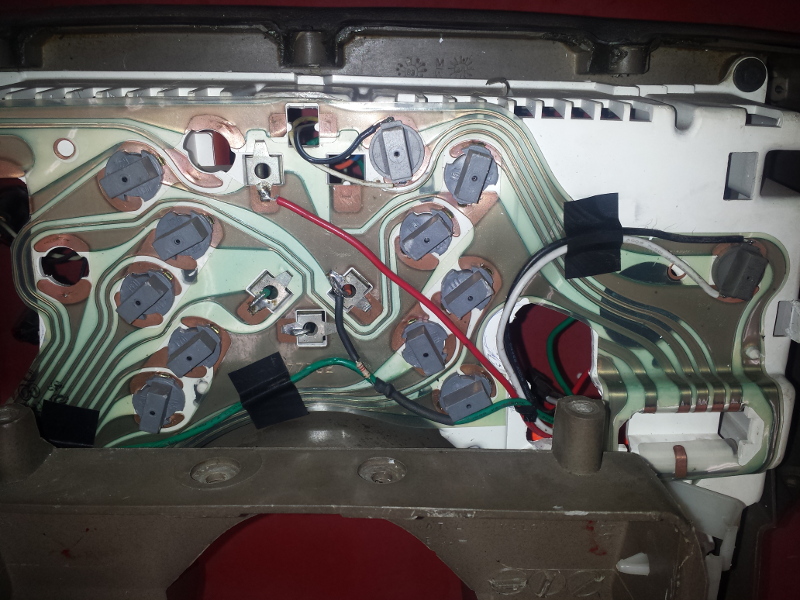

I then chose to add the pull-up resistor in the back of the instrument cluster.

In this location, I could tap into the two electrical points that I needed.

-The green wire is the tach signal wire.

-The resistor is then attached to the signal wire and the opposite end attaches to a keyed-on +12V.

A little video to show that it actually works.

[This message has been edited by Lunatic (edited 09-09-2018).]

|

|

|

wftb

|

SEP 09, 09:45 AM

|

|

|

Thanks for adding that Shayne. And for those that have never visited his thread(look for Lunatic in the construction zone) there is a wealth of knowledge and how to stuff in his thread. No matter what type of ecotec you install you could not go wrong using his methods.

|

|

|

longjonsilver

|

SEP 09, 12:12 PM

|

|

Thanks Lunatic, i had read your thread, but had lost it and was wondering where the thing about the gages was? Now i know.

So i guess if i source an LE5 motor, and add a stock supercharger, i will get a reliable engine? i don't need a lot of HP - i must only have 85 HP now, 200HP would be fun and not too much weight in the rear, i guess.

thanks

jon

edit: The F23 tranny weighs about 45 lbs more than the stock Muncie or Getrag trannies. Does your estimate of the weight of the ecotec include the weight of the transmissions? i suspect that the weight gain of the F23 transmission makes up for any loss of weight from the transition from the 2.8 V6 to the ecotec. Dunno about the iron duke engine.

------------------

Astronomy says we will find a coded signal from outer space. Then we'll KNOW that life exists there, for coded signals aren't by chance.

Biology says there are coded genetic signals in every cell, but we KNOW that no intelligence created life.

I'm the original owner of a white ' 84 2M4 purchased Dec 10, 1983 from Pontiac. Always garaged, no rust, 4-wheel drifts are fun![This message has been edited by longjonsilver (edited 09-10-2018).]

|

|

|

wftb

|

SEP 25, 10:12 AM

|

|

When I first ran my 2.2 it was bone stock. It was noticeably faster than my rebuilt 2.8. The 2.8 had forged pistons and was bored 30 thou over and complete rotating assembly was balanced. It isnt just the lighter weight, it is the way the ecotec delivers full power over a broader rpm range that makes it a better choice for a sports car over a 2.8.

The weights quoted for the 2.2 in one of the links is a fully dressed weight. I don't know if the other engines are fully dressed or not (alternator,AC compressor and bracketry etc). The main engine mount and related hardware (cavalier version) weigh 8 lbs and the lower stock dogbone at least 6 lbs.I don't know what the alternator and compressor weigh but you can see how hard it is to compare apples to apples. Making your own motor mounts saves weight.Alternator and AC compressor bolt directly to ecotecs without external mounted brackets also saving weight. There is only one serpentine belt and it is very short.

When the LE5 came out in the Solstice, it was rated at 178HP. Different applications had different ratings but even without a supercharger you are doubling your HP with a stock LE5 over the duke.

My F23 has been perfect as long as I have had it. It had 60000 KM on it when I got it and I have put on around 120000KM on it since. I am still using the original clutch that it came from the wreckers with. I highly recommend using the GM OEM clutch. The extra 45 lbs over the 4 speed that came in my car is worth it for the reliability.

|

|

|

Lunatic

|

SEP 26, 07:14 AM

|

|

| quote | Originally posted by longjonsilver:

edit: The F23 tranny weighs about 45 lbs more than the stock Muncie or Getrag trannies.

|

|

I believe your statement is incorrect Jon.

The 4 speed is the lightest trans by a slim margin, then the 282 (39.9 KG / 88 lbs) then the F23 (46 KG / 102 lbs) and finally the F40 is the heaviest by 30-40 lbs (56 KG / 123 lbs).

|

|

|

wftb

|

SEP 27, 04:21 PM

|

|

I did a bit of work over the last couple of days. Ever since I put the heavier springs on I have not been happy with the ride harshness. But I put up with it, telling myself that it will be better that way when I take it for a track day. But here it is almost October and I heavent made a track day yet.

So I decided to put my lighter set of springs on (350 frt 200 rear vs 450frt 350 rear) to smoothe out the ride. Took about 4 hours.

I decided to set up the shocks with a lot stiffer settings than normal. I set the rears at 8(stiffest setting is 18) and the fronts at 5 and drove about 20 KM. It rode about the same as with the heavier springs set at 1 all the way around. This was on roads I drive all the time so it was easy to make the comparison.

I needed to drive to Hanover to pick up a part so I thought I would drive over with the front at 3 and the rears at 4. Then I drove back with all the shocks at 1. On the way over ride was noticeably better but still too noisy. I lke a car to be on the stiff side but with a quiet suspension. Bumps should be seen and felt but not heard.

Driving the same roads on the way back with the shocks set at 1 that was achieved. Instead of a bang when the car hit bad expansion joints or things like a recessed storm drain now all you here is a low whump noise.

I am still going to track days in the future but I am not going to put my heavier springs back on. The range of adjustment on my shocks is something I have not utilized enough. If you set these shocks at 18 the effect would be almost like replacing the shock with a piece of pipe. So I should be able to adjust the shocks to get the roll control I want without stiffer springs. For the rest of this Fiero season, I am going to enjoy the quiet ride.

I even cleaned the calipers:  [This message has been edited by wftb (edited 09-27-2018).]

|

|

|

wftb

|

DEC 13, 06:08 PM

|

|

The Fiero is now away for the winter. The suspension has worked great this year, only one small thing to fix over the winter. One rear lower control arm has developed a bit of fore and aft slop because I did not get a smooth cut on one of the bushings causing wear on the rear delrin washer. Only about 1/32 of an inch and will be easy to fix by making a thin sheet metal washer to protect the delrin from the end of the bushing. No detectable wear in any of the Del A Lum bushings or the Febest bushings installed in the front lower control arms.

On the tuning front I learned 2 things at the end of the summer : Once you change your injectors to something in the range of almost double your stock size, both my water meth injection and the Vortec 6:1 FMU become useless and can actually cause some harm. Earlier in the thread I describe how I had to dial the W/M way back so it did not cause KR - now it is effectively shut off. With the larger injectors there is no point to having the FMU in the circuit, the extra pressure just sends too much fuel in and then the ECM just dials it back. But in the meantime the fuel pump is putting out more pressure and that shortens its life. I am on my 3rd fuel pump now. This is an aftermarket unit and it is starting to behave like it might be wearing out.

So I blocked off the boost signal to the FMU and now the pump is behaving normally again. It might die anyway I will find out next year.

------------------

86 GT built 2.2 ecotec turbo

rear SLA suspension

QA1 coilovers on tube arms

|

|

|

wftb

|

JAN 28, 04:56 PM

|

|

Being retired now I have lots of time to work on my hobby cars. But it also means I have a lot less money to play around with. So instead of paying for insurance for 2 summer cars, I need to cut back to 1 summer car. Since I am busy getting stuff done to the 91 Civic wagon (getting power steering working, installing an OEM roof rack, and it needs new axles), I am going to drive the wagon this summer. Once I have the wagon finished and back on the road, I am going to start a major Fiero project that will likely take me a year.

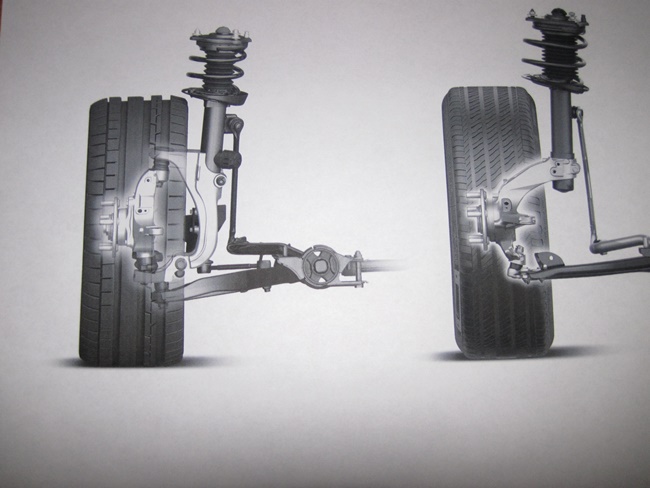

I was looking the other day at pics of custom made cradles and I have decided to make one. I have pretty well taken the 86 rear chassis based SLA suspension as far as I can. There is still room for improvement but the gains would be minimal.

There are 2 big things I want to change: I want longer upper and lower control arms and I want the arm mounts to be at right angles to the car rather than running on the strange

angle that the stock ones are at now. I also want a spindle that incorporates an upper and lower ball joint instead of using an adapter.

For instance, a spindle from the new Civic Type R:

I have not found one yet but GM and Ford also have a strut suspension that utilizes 2 ball joints. Or I could make my own spindles, utilizing some stronger newer FWD bolt on bearing packs. The Type R spindle assembly is available for a mere 327.00. Per side. They probably wont make it in to my local wreckers any time soon. 4 wheel drive cars that use upper and lower control arms might provide some thing too.

This project will be the biggest thing I have tackled yet. I will be using the rear coilovers I have on the car now, quite happy with the way they work. The wheels I have also have an extra larger bolt pattern on them so I will not have to buy new wheels if I cant find a suitable 5X100 bearing assembly. My front and rear tires are not interchangeable any ways.

Edit: It is now 2020 and I have still not started on the custom cradle project.Later in the thread you will see some further suspension mods that worked out well. And none of the spindles I want have made their way into our local pick and pull yet. So I am kind of doubting I will make a cradle.[This message has been edited by wftb (edited 01-01-2020).]

|

|

|

|