|

| Need Help Wheel Studs (Page 1/3) |

|

Chief08

|

FEB 19, 04:52 PM

|

|

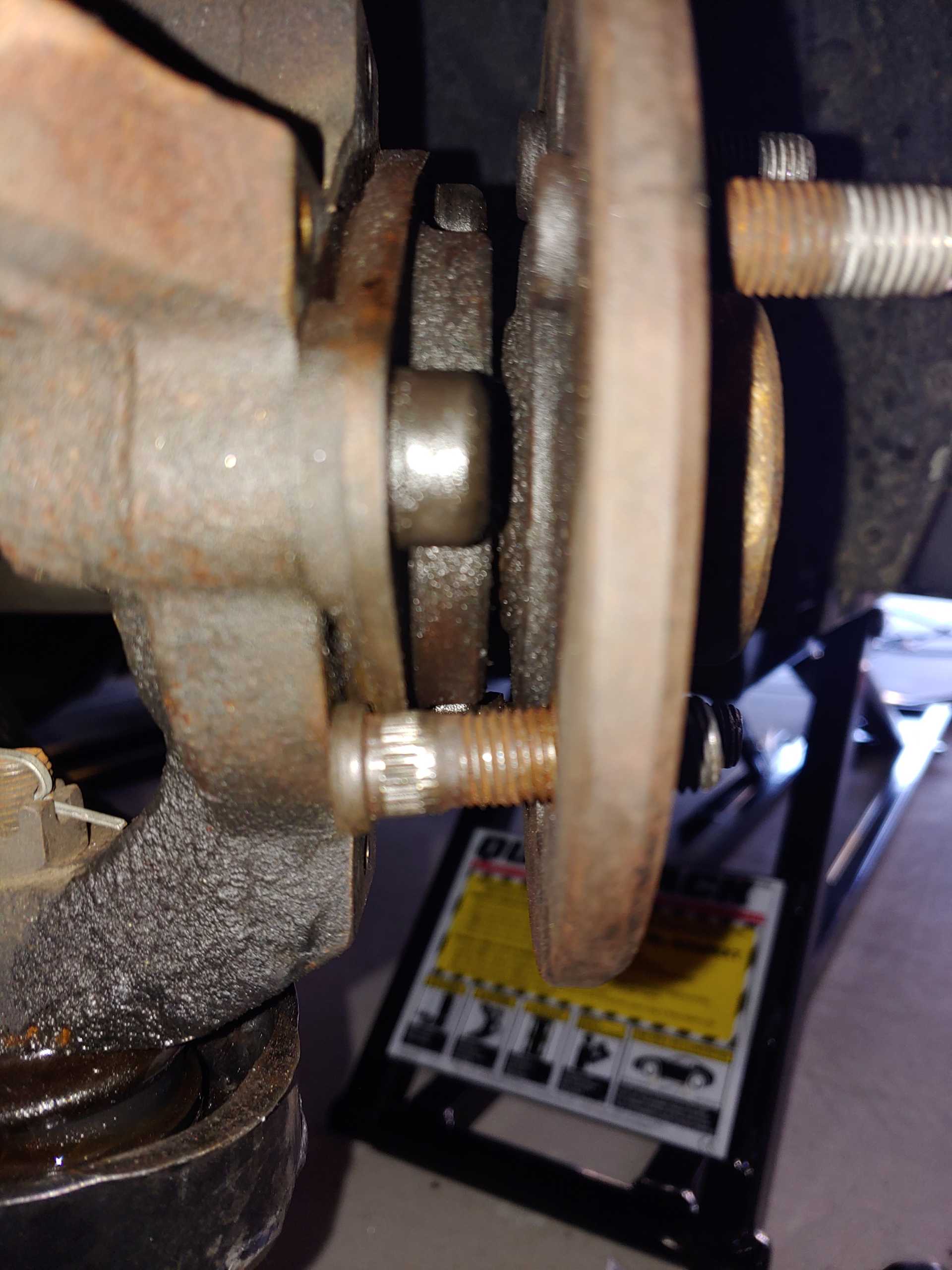

I am finding impossible to remove the wheel studs. Even at the recommended 4 and 8 positions they won't come out as you can see in the picture. I thought about removing the hub but the bolts are stripped. Anyone have any ideas? I'm stuck on this one. Also, I'm replacing the current studs with longer ones, so if these can't come out, I have no idea how I would get the new ones in.

|

|

|

fieroguru

|

FEB 19, 05:54 PM

|

|

|

On the 88 fronts you have to loosen the wheel bearing hub and pull it out slightly or remove it to install the wheel studs.

|

|

|

Chief08

|

FEB 23, 10:05 PM

|

|

|

The hub bolts are stripped and I'm not sure how to get them out. I broke a drill bit and an easy out off in one of them. There isn't much room between the hub and the structure to cut/grind etc.

|

|

|

Patrick

|

FEB 24, 03:53 AM

|

|

Sounds like an ugly mess. Might be easier to remove the knuckle and then deal with it... whether it's by you or a shop.

|

|

|

pmbrunelle

|

FEB 24, 12:23 PM

|

|

To get the studs out of the way, you can either pull them back into place with a lug nut + stack of washers, or you can cut then in half with an angle grinder + cutoff wheel.

Easy-outs are almost never the solution to rusted/stuck fasteners... if the original bolt head didn't have the strength to transmit the torque required to break the bolt free, I don't see how the easy-out could work any better.

For the bolts, I would try welding a hex bolt onto the head of your stripped bolts. Then, you'll have a hex you can grab onto with a socket.

If the weld breaks, weld it again with a new bolt. The heat should help loosen things; while the bolt head is still hot, shoot some penetrating oil on it.

I don't know how necessary it is to remove the knuckle from the car; it depends if you have a good way to secure the knuckle in a vise off the car. The knuckle is an awkward shape; the car provides a secure hold of the knuckle.[This message has been edited by pmbrunelle (edited 02-24-2020).]

|

|

|

Chief08

|

FEB 24, 12:48 PM

|

|

| quote | Originally posted by pmbrunelle:

To get the studs out of the way, you can either pull them back into place with a lug nut + stack of washers, or you can cut then in half with an angle grinder + cutoff wheel.

Easy-outs are almost never the solution to rusted/stuck fasteners... if the original bolt head didn't have the strength to transmit the torque required to break the bolt free, I don't see how the easy-out could work any better.

For the bolts, I would try welding a hex bolt onto the head of your stripped bolts. Then, you'll have a hex you can grab onto with a socket.

If the weld breaks, weld it again with a new bolt. The heat should help loosen things; while the bolt head is still hot, shoot some penetrating oil on it.

I don't know how necessary it is to remove the knuckle from the car; it depends if you have a good way to secure the knuckle in a vise off the car. The knuckle is an awkward shape; the car provides a secure hold of the knuckle.

|

|

I cut the stud bolts and removed them, also, I don't have access to a welder unfortunately. I tried heating the hub bolts, but the heads are round and I can't get a good grip on them. I tried using a pipe wrench, but there just isn't enough room. All of the removal methods that I have read about assume that the bolt is in the open, which is obviously not the case here. I thought about an extractor socket, but any socket that will fit over the bolt head will not fit through the hole in the hub. Bad choice by GM to use a torx bolt with a rounded head.

|

|

|

Patrick

|

FEB 24, 03:31 PM

|

|

| quote | Originally posted by pmbrunelle:

I don't know how necessary it is to remove the knuckle from the car...

|

|

If the OP decides he requires a shop to remove those bolts, it might be more practical to take just the knuckle there as opposed to towing the whole vehicle.

|

|

|

Dennis LaGrua

|

FEB 24, 05:12 PM

|

|

You can cut the studs with a cutting wheel but then be faced with freeing up enough clearance . You will still need to loosen the hub but there are sockets that you can buy that will grab onto rounded nuts.

Rounded bolts/nuts removal sockets

------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE " [This message has been edited by Dennis LaGrua (edited 02-24-2020).]

|

|

|

Chief08

|

FEB 24, 07:13 PM

|

|

|

I finally got them out by heating them, pouring cold water on them, then soaking with penetrating fluid. Then I took the next bigger sized torx bit and hammered it in. Using a pipe on the end of the ratchet, I was able to break them loose.

|

|

|

pmbrunelle

|

FEB 24, 07:25 PM

|

|

| quote | Originally posted by Chief08:

Bad choice by GM to use a torx bolt with a rounded head.

|

|

Now's your chance to install bolts that are to your liking!

Not catering to the handyman 30+ years later after the car's end-of-production wasn't necessarily a bad move... the objective of most public companies is to create shareholder value. A Torx bolt may have been the best way to do that.

|

|

|

|