|

| The White Bug (Page 6/42) |

|

pmbrunelle

|

JUL 01, 07:43 PM

|

|

Most of the steel plates I'm cutting with a hacksaw, angle grinder + cutoff wheel, drill press for internal corners. Bench grinder and files for the last bits of material removal.

Either I'm making 1:1 paper/cardboard models, and tracing the result on the steel, or I'm drawing lines directly on the steel with a ruler, compass, etc.

Only for the more "precision" work, or for shapes that would be a PITA to do with hand tools, then I make a *.dxf drawing, which I have cut by a metal shop in my town. They have a plasma-cutting table.

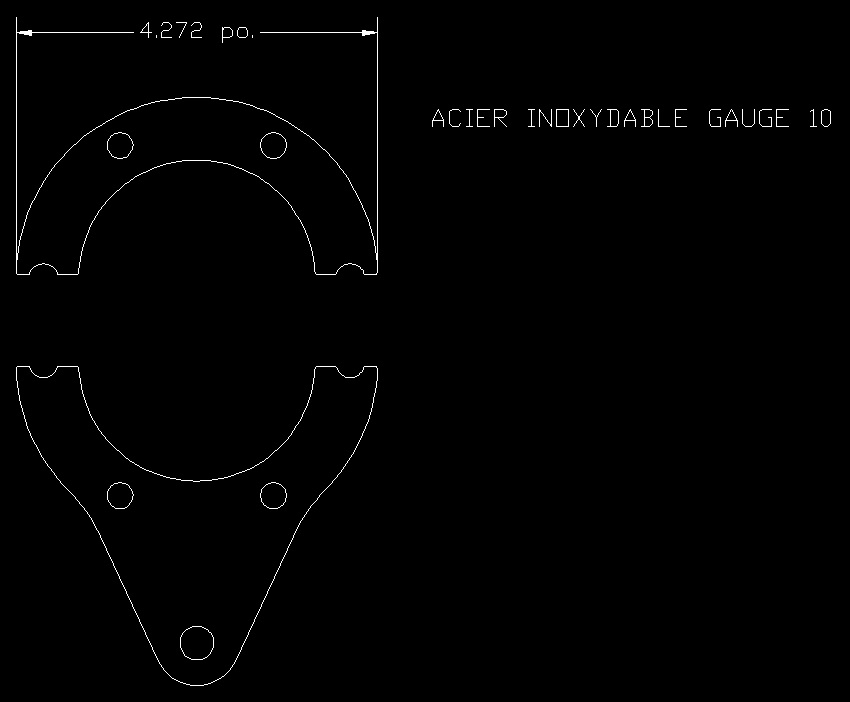

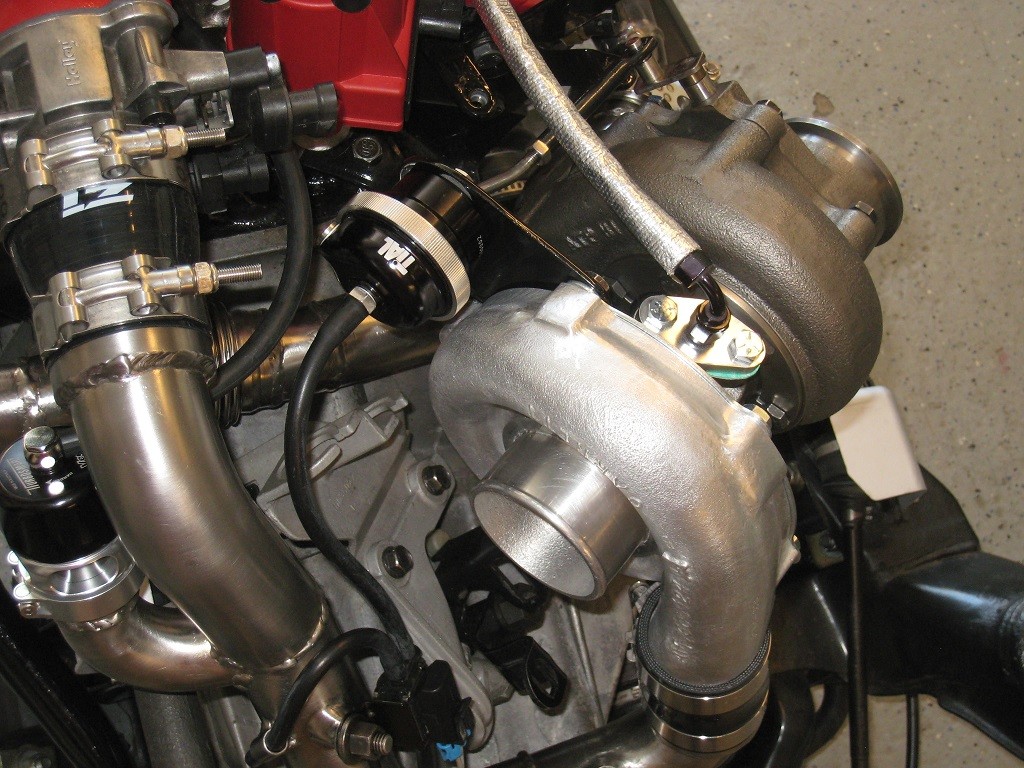

If we look at the turbo support components, the turbine housing clamping plates were something I outsourced. I made this *.dxf and had it cut from stainless:

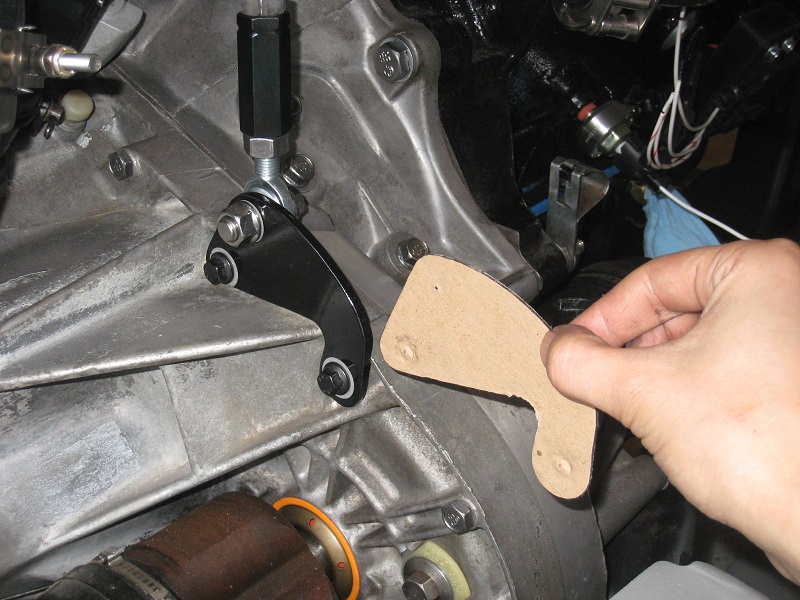

On the other hand, the bottom mount that bolts to the transaxle was easily within my capabilities. I did the design in cardboard, traced it in steel, and then cut it out:

It was just faster and easier to DIY it. I sidestepped the difficulty of digitizing a semi-arbitrary shape (as opposed to something easy to measure, such as a circle or rectangle). Outsourcing also brings the administrative burden of having to keep tabs on the supplier.

|

|

|

Will

|

JUL 03, 09:55 AM

|

|

|

LOL at seeing dimensions in inches on a drawing labeled in French...

|

|

|

pmbrunelle

|

JUL 20, 08:36 PM

|

|

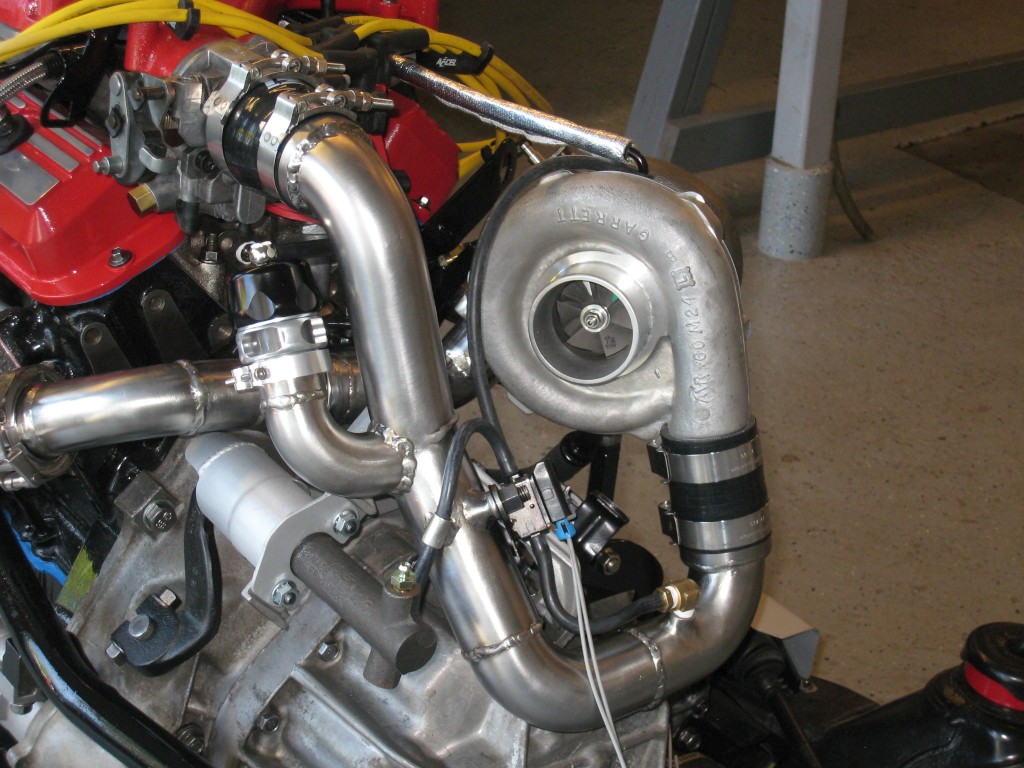

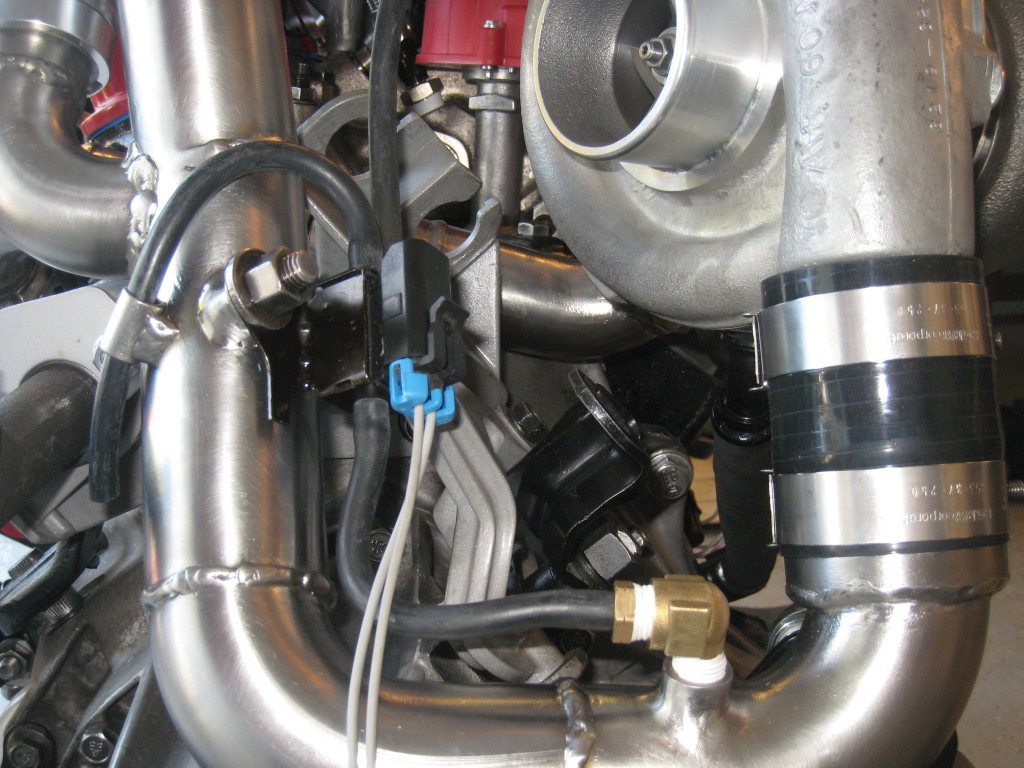

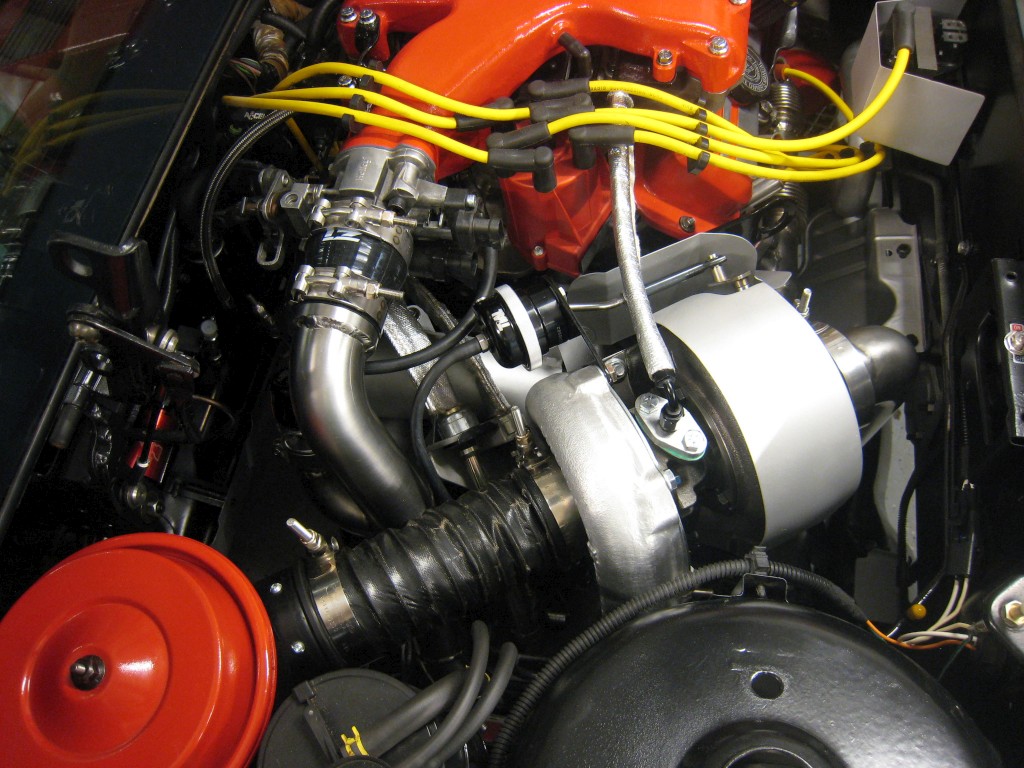

I finished the air pipe linking the turbo's compressor outlet to the throttle body:

I ended up going with the Turbosmart Vee Port Pro BOV. It's rated to be capable of venting 600 hp of compressed air, whereas the TiAL Q is rated at 1800 hp... which is overkill for my Fiero. The Turbosmart unit is physically smaller than the TiAL piece, hence I decided to go with the more compact, easier-to-package solution:

Here is the GM 3-port boost control solenoid (used on the Syclone/Typhoon). This will be computer-controlled, allowing the computer to increase the boost pressure beyond the wastegate spring setting:

|

|

|

Fiero38SC

|

JUL 22, 08:49 AM

|

|

|

Awesome work. Please keep it coming.

|

|

|

pmbrunelle

|

JUL 29, 12:43 PM

|

|

I installed the TiAL MVI 2.5 wastegate actuator.

Its opening pressure is configurable by installing different combinations of springs:

http://www.tialsport.com/do...vi2.5springchart.JPG

I own the red and green springs, which should provide enough flexibility for me. I expect to fine-tune the boost pressure with the electronic solenoid, rather than by spring selection.

I got the bent-rod version of the actuator, so that it would clear the compressor housing.

|

|

|

John W. Tilford

|

AUG 02, 08:20 AM

|

|

Did this Fiero have any Kentucky owner history? It looks so much like my first Fiero, a 1986 white/black notchie with the same interior colors, and 2.5 "Iron Duke". The Kentucky buyer called me about an hour after driving away . . "How do I get this gas filler cap cover open?"

------------------

John W. Tilford

|

|

|

pmbrunelle

|

AUG 02, 10:14 AM

|

|

It's definitely not your old Fiero. Mine has the (Canadian market) Z49 RPO code, and it still had an Ontarian car dealer sticker on the decklid when I took possession; seems like it spent its life in Canada. Additionally, mine is a 1985, and came with the 2.8 V6.

When I bought my first Fiero, I too struggled at the gas station with trying to find the filler cap release!

White bumperpad notchies were one of the most commonly produced Fiero body styles.

|

|

|

pmbrunelle

|

AUG 18, 12:12 AM

|

|

The powertrain is in the car (for the moment), and everything seems to fit.

The main steps remaining before driving the car are to fabricate the exhaust piping from the turbine outlet all the way to the exit, and lastly tweaking the wiring harness as needed.

|

|

|

pmbrunelle

|

SEP 15, 09:08 PM

|

|

I have mostly completed the post-turbo portion of the exhaust. It's 2.5" all the way to the exit. I am using a Magnaflow muffler.

Next, I must determine the exhaust hanger configuration.

|

|

|

pmbrunelle

|

OCT 07, 04:49 PM

|

|

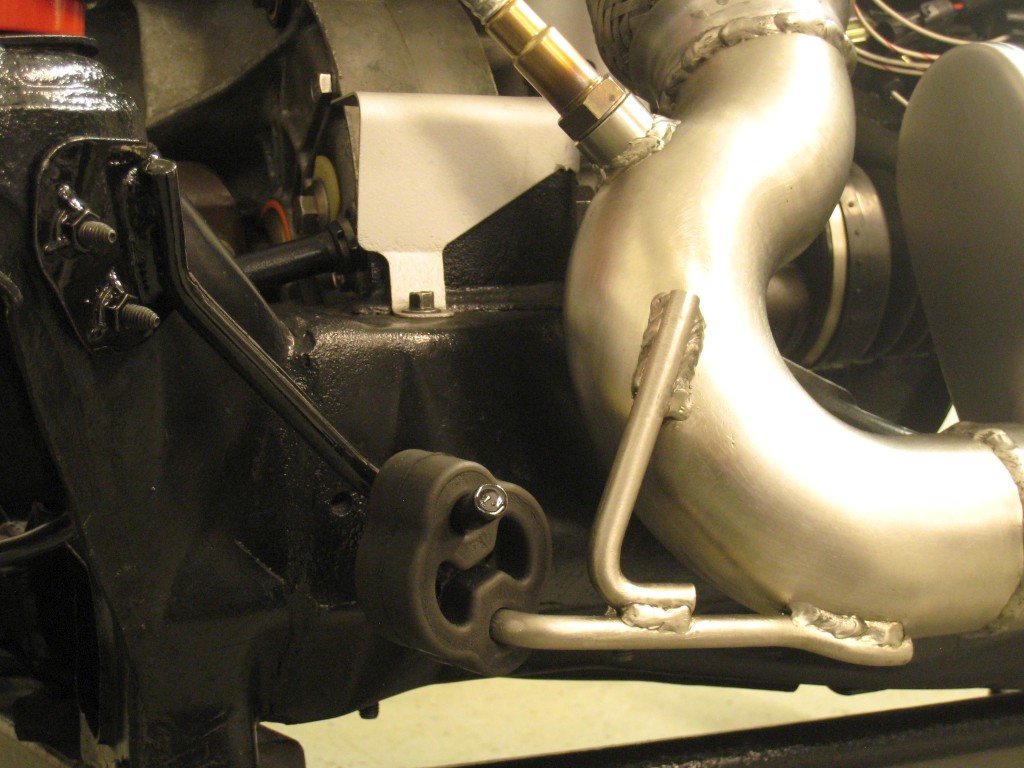

The exhaust is now supported from the cradle at three points:

Here is a typical hanger. I'm using 3/8" round rods, bent and welded as required. The actual rubber isolators are from a Ford Freestar minivan:

Here is the bending tool I purchased to bend the rods.

Huth BenPearson HMRB6017:

https://www.youtube.com/watch?v=1nyNZ67XIvk

The bender is rated for bending up to 3/8" round steel rod. 3/8" round is really at the tool's limit. I used a cheater bar on the handle to get the job done.

|

|

|

|