|

| Greasable control arm bushings (Page 1/2) |

|

RB_Fiero

|

OCT 22, 08:41 PM

|

|

I will be replacing all of the bushings on my 85GT. I have done a lot of reading, but I have not found control arm bushings with a grease filling. I am considering polyurethane, but the grease must wash off at some time, and when it does I don't want to disassemble control arms to grease them. I am hoping that there is an alternative that is firm like the poly, but has a grease fitting. I do not have the means to machine my own bushings.

Does such a bushing exist?------------------

Ron

|

|

|

wftb

|

OCT 22, 09:28 PM

|

|

|

You can use poly , just drill and tap holes that you can thread grease fittings in to. Not the easiest thing to do on stock control arms but it only takes time and patience and common hand tools. A long time ago I bought a set of delrin aluminum bushings (Del-A-Lum trade name, look them up on Summit web site) from West Coast Fiero .These were greasable with fittings and designed to fit the stock 84-87 front control arms. I do not see them listed on his website any more but maybe Chris West might give the part #s out ? Or maybe he could get you some never hurts to ask.

|

|

|

wftb

|

OCT 22, 09:38 PM

|

|

|

Tried to post a link to Summits website and it just sends me to some bogus hosting site. So everyone has to go look for themselves I guess , sorry. [This message has been edited by wftb (edited 10-22-2017).]

|

|

|

RB_Fiero

|

OCT 22, 09:52 PM

|

|

| quote | Originally posted by wftb:

You can use poly , just drill and tap holes that you can thread grease fittings in to. Not the easiest thing to do on stock control arms but it only takes time and patience and common hand tools. |

|

I am sure that I can drill through the old bushing walls and thread in a grease fitting; likewise I could drill through the bushing, but lining the two holes up may be impossible. Can a groove be Dremeled in the outer surface of the bushing to allow for some misalignment of the holes and provide a path for the grease to follow?

|

|

|

Patrick

|

OCT 23, 01:56 AM

|

|

| quote | Originally posted by RB_Fiero:

Can a groove be Dremeled in the outer surface of the bushing to allow for some misalignment of the holes and provide a path for the grease to follow?

|

|

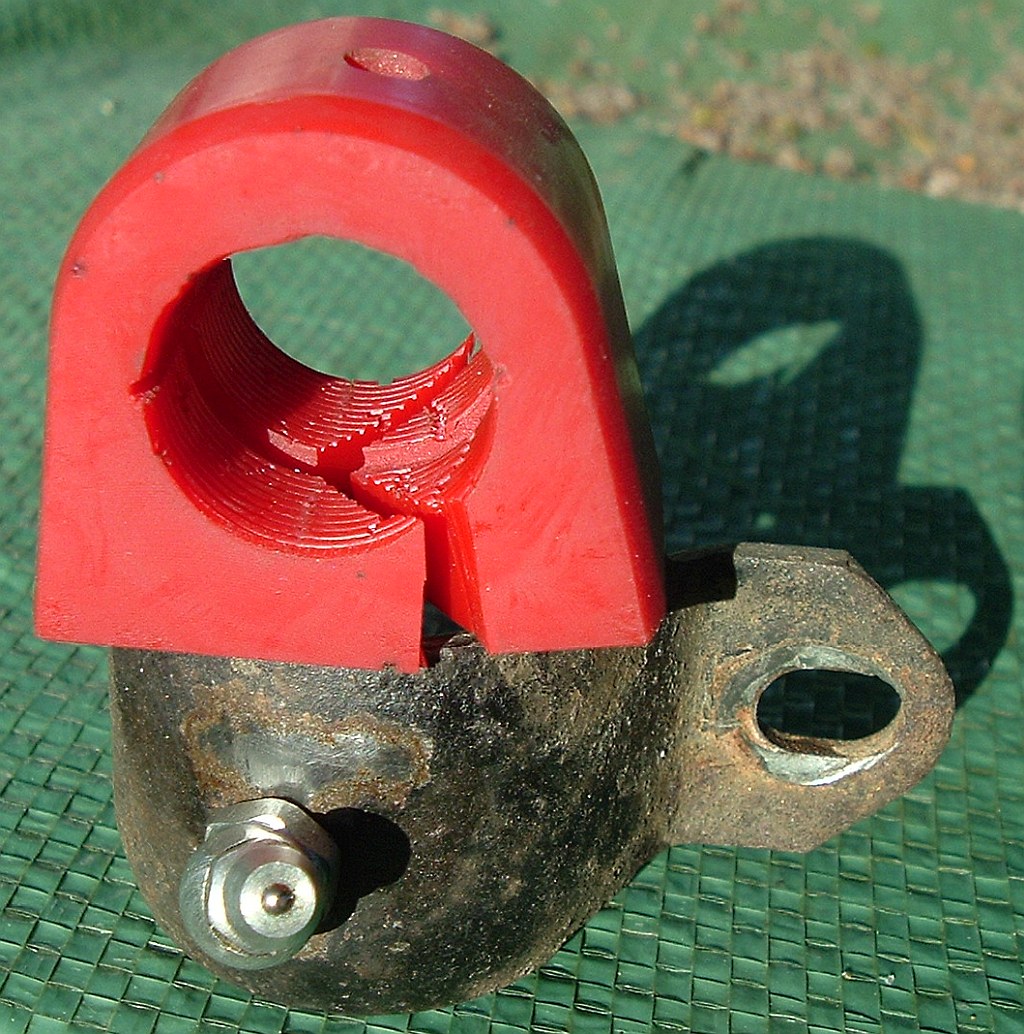

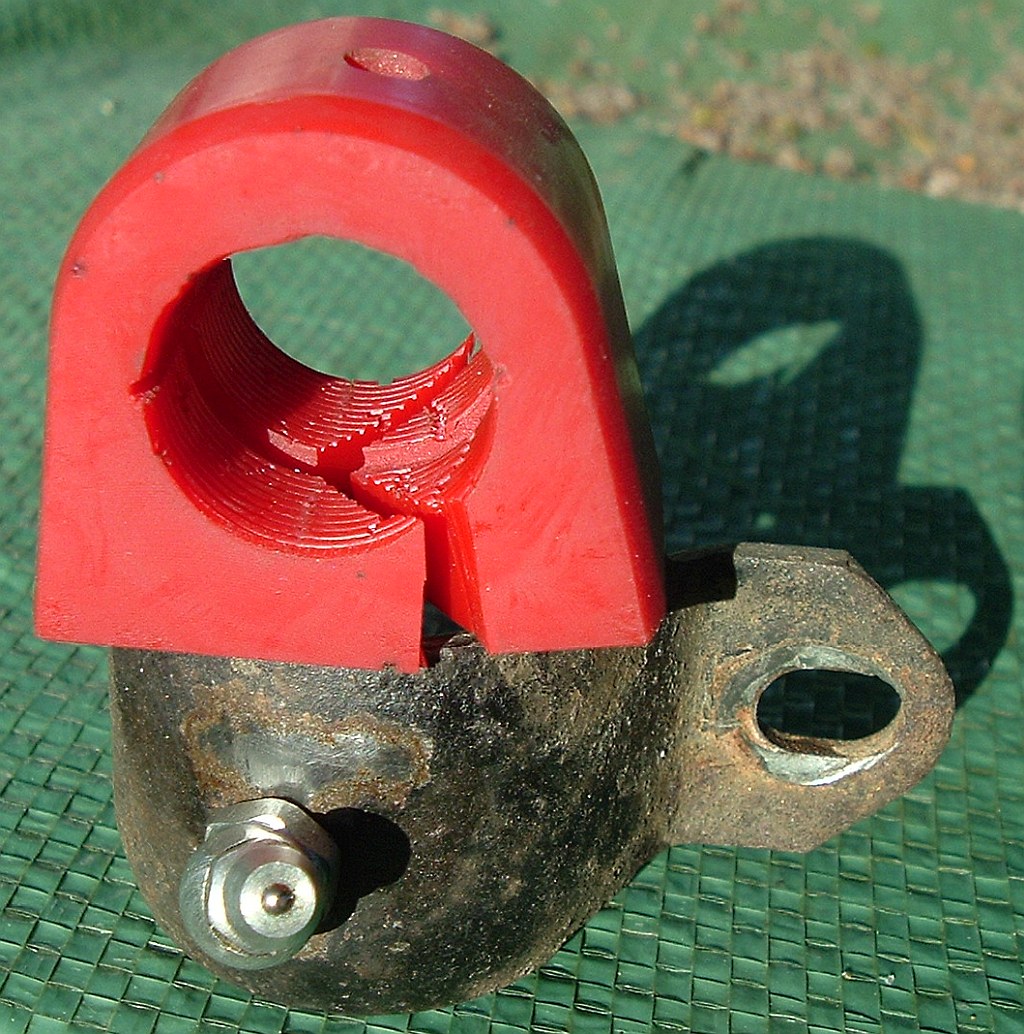

This is a totally different situation, but I dremeled out a channel for lithium grease to follow on the inside of these poly sway bar bushings for my Subie when I added the zerk fittings. Worked out really well... no squawking!

[This message has been edited by Patrick (edited 10-23-2017).]

|

|

|

wftb

|

OCT 23, 03:10 AM

|

|

|

When I did it, I drilled the holes whith the bushing in place. Then thread the hole and it lines up. Just take it apart to clean the metal out of it and put the grease fitting on after you push the bushing back in. You want the poly to rotate with the arm and the grease to go between the poly and the centre metal bushing and that centre bushing needs to be cranked down tight with the mounting bolt so it will never move. The grease fitting also helps the poly to stay in synch with the arm as well. As Patrick did above, you can make a groove on the inside of the poly so the grease travels around the inner metal bushing. [This message has been edited by wftb (edited 10-23-2017).]

|

|

|

RB_Fiero

|

OCT 23, 08:30 PM

|

|

| quote | Originally posted by Patrick:

... I dremeled out a channel for lithium grease to follow on the inside of these poly sway bar bushings for my Subie when I added the zerk fittings. Worked out really well... no squawking!

|

|

It looks like this bushing didn't do so well, but you say it did; I don't understand.

|

|

|

wftb

|

OCT 23, 10:19 PM

|

|

|

It is a sway bar bushing. They are split so they can be pulled apart to go around the bar and then the housing goes over the poly and bolts it all tight to the frame.

|

|

|

Patrick

|

OCT 24, 03:20 AM

|

|

| quote | Originally posted by RB_Fiero:

It looks like this bushing didn't do so well, but you say it did; I don't understand.

|

|

I don't understand why you feel my bushing "didn't do so well". Both it and its partner have done very well.

wftb did a good job describing the task I had tackled, but if you have any further questions, feel free to ask.

|

|

|

RB_Fiero

|

OCT 24, 06:10 PM

|

|

| quote | Originally posted by Patrick:

I don't understand why you feel my bushing "didn't do so well". and (from WFTB) It is a sway bar bushing. They are split so they can be pulled apart to go around the bar |

|

Okay, now I get it. I thought the split in the bushing was the result of bushing failure, and now I see that you couldn't install the bushing unless it had such a split feature.

So, if I understand it correctly, you started with a bushing that already had the radial grooves (for grease retention) on the inside bore, and added a drilled hole for the Zerk fitting and a groove on the inside bore to allow grease to flow across those radial grooves. Have I understood your bushing modification correctly? Is so, what did you use to make the groove on the inner bore.

Assuming that I have understood the modifications you made correctly, this is exactly what I would like to do to my control arm bushings. I want the poly bushing, but I don't want to remove bushings in the future to grease them. Additionally, do you know of anyone who has made the same modifications to a control arm bushing; they bear a higher load?

|

|

|